By Greg Solmundson

When deciding on an aquatic vessel, potential customers are at times unaware of the vast potential a hot tub can present when it comes to enhancing a leisure space. Most clients have an appetite for a unique design—whether integrating a hot tub into a newly constructed home or an existing residence undergoing a renovation. That said, the most common request Ark Custom Pool & Spa International faces from customers is to have a personalized design that differs from traditional concepts.

Facilitating personalized design features can be easily managed with the ability to customize the hot tub first, then working on other areas of the project. For example, a hot tub engineered from stainless steel is not only available in any size or configuration, but also provides a bright, sophisticated-looking feature that is capable of withstanding harsh winters. Further, the ability to include ceramic and glass tile in a variety of colours and patterns allows the homeowner to easily integrate their hot tub with the surrounding environment (e.g. landscaping, decking, façade of the house, etc.) to match the vision they have for their outdoor space.

One recent project, which included a stainless steel hot tub as part of a complete backyard makeover, was completed in Calgary, Alta. On this particular job, VisionScapes, a local landscaping firm, commissioned a portion of the project to Ark Custom Pool & Spa International to design a custom hot tub for the property, which would be nestled amongst other outdoor amenities.

How did it all begin?

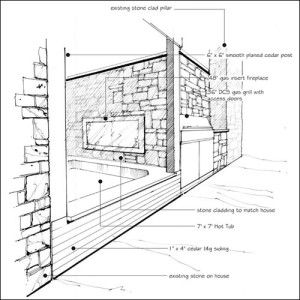

Upon receiving the invitation from the landscape company, a meeting was arranged with the customer to identify the specific features and designs they were interested in. To help this along, a preliminary conceptual design of the client’s property was rendered. The idea of presenting a stainless steel hot tub with integrated tile trim that was partially recessed into the ground next to a natural gas fireplace was very appealing to the customer.

Careful consideration was made by listening to the homeowner’s suggestions and ideas, which ultimately influenced the final design. The ability to provide the client with any shape or size hot tub helped to accelerate the decision-making process and enabled them to make the necessary design alterations.

Based on these discussions, it was clear the homeowner was looking to maintain sharp lines with the hot tub being a complementary feature to the preliminary design. Once the general design was established, the customer selected a tile combination to be applied on the hot tub’s interior trim, which also provided a basis for selecting the surrounding stonework, concrete colouring, and furniture combinations.

Controlled environment manufacturing

After finalizing the size and shape of the hot tub, and before the stainless steel vessel entered the production floor, the engineering team produced a detailed drawing for each manufacturing assembly team. Then, each sheet of stainless steel was passed through a state-of-the-art computer numerically controlled (CNC) laser machine, which cut the steel precisely based on the design. After being cut, the steel was formed using a press brake and then welded together. Once assembled, the tiles were installed using a proprietary epoxy adhesive. Plumbers and insulators then installed the hot tub’s hydraulic functions.

When the manufacturing process is complete, the hot tub undergoes quality control checks and operational tests before it is shipped to the project site in a protective crate.