By Sue Robach

Automatic pool cleaners can simplify pool maintenance, but only when they are functioning properly. Thankfully, most pool cleaners work well most of the time. Occasionally, however, a pool may not be as clean as the owner would like, so it is important to know a few things about ensuring the long-term successful use of these relatively simple machines.

Before moving on to other potential issues, first ensure the system was installed correctly. Each cleaner type—suction, pressure and robotic—can and should be adjusted at the time of installation.

For suction and pressure cleaners, hoses must be the correct length and free of bends or kinks. To ensure proper positioning of the cleaner, suction cleaner hoses require weights (to make the hose sink), while pressure cleaner hoses have floats (to keep the hose at the surface).

Robotic cleaners and their accessories may require assembly and adjustments. These will vary by cleaner type and model; the owner’s and/or installation manual will provide the necessary details.

Routine maintenance is key

Once it is verified the cleaner was installed properly, if possible, try to determine when it was last inspected for general wear and tear. This is among the things that should be done regularly—annually in most cases, but more frequently depending on the cleaner’s use patterns.

When operating correctly, pressure and suction cleaners should move throughout the pool. Some cleaners have programmed cycles, while others operate in random patterns. Both approaches should enable the cleaner to cover the entire pool. If the cleaner occasionally stops or misses particular areas, it may require some adjustment. Some of the things that may require fine-tuning are flow and/or pressure (suction or pressure cleaners), thrust jets and backup valves (pressure).

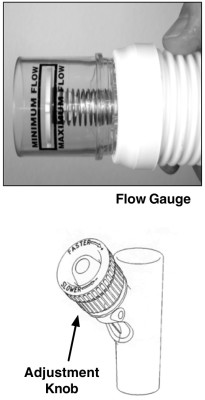

To adjust the flow on suction cleaners, turn the pool pump off. Remove the cleaner head and connect a flow gauge to the end of the leader hose, keeping the hose submerged to prevent air from entering. Some suction cleaners have inline vacuum gauges inserted in the hose between the first section from the skimmer and the next hose extension. With these models, an ancillary flow gauge is not required. Then, turn the pump on. As it is running, adjust the regulator valve (on equipped models) until the indicator settles between maximum and minimum flow. (Refer to the manufacturer’s manual for proper vacuum ranges.)

When satisfied with the flow setting, turn the pump off again, remove the flow gauge and reconnect the cleaner to the hose. Again, make sure to keep the hose submerged to prevent air from getting in the line.

Keep in mind, optimizing the water flow in this manner does not necessarily maximize flow through the cleaner itself. In fact, less suction may better enable a random cleaning pattern.

If a pressure cleaner’s backup valve is not cycling, its random cleaning pattern may be compromised. To check this, hold the valve out of the water. The jet should come on for about 30 seconds and then rest for about 3.5 minutes. If this is not the case, the backup valve may need to be adjusted or replaced.