Expert tips for safety cover installation

By Paul Hunter

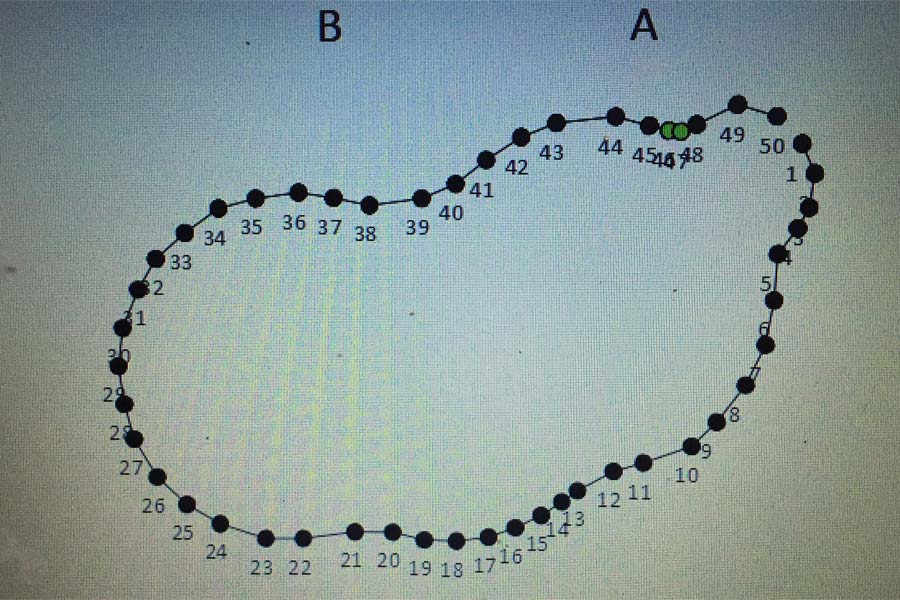

While there are still some standard pools around, an increasing number of homeowners are opting to renovate their backyard oasis, adding walk-in stairs, slides, and waterfalls. In fact, most new pools today have unique, irregular shapes and, with custom safety covers becoming the industry norm, ‘A-B’ measurements are required to obtain the correct pool dimensions.

Most expert safety cover installers start this process by using chalk to make small marks along the pool edge (on the coping or deck) approximately 0.6 to 0.9 m (2 to 3 ft) apart, including the edges of walk-in stairs and attached spas—the space between these markings do not need to be exact. The first mark should be identified as number ‘1.’

Next, two stakes (e.g. pipes, rebar, or screwdrivers will suffice) are inserted into the grass or garden alongside the pool. These stakes should be at least 0.9 m (3 ft) away from the water’s edge, and a minimum of 3 m (10 ft) apart. The installer should record the distance between these stakes on paper.

When standing beside the stakes, facing the pool, point ‘A’ is identified by the stake on the left, and point ‘B’ is the stake on the right. The entire pool should be on one side of the ‘A-B’ line. If this line is set-up within the curve of an irregular shaped pool, or within the corner of an L-shaped pool, the measurements will be incorrect.

Using a 30-m (100-ft) tape measure (or longer if required) attached to the end of point ‘A,’ the distance between it and mark ‘1’ is recorded as ‘A1.’ All of the measurements should be rounded to the closest inch. The distance from ‘A’ to the second mark is recorded as ‘A2,’ and so on. Measurements are taken around the pool circumference, and always end with the same point started at (A1), to double-check the stake has not moved.

Once the ‘A’ measurements have been taken, the tape end is attached to stake ‘B,’ and the measurements for ‘B1,’ ‘B2,’ etc., are then recorded.

If there are obstructions within 457 mm (18 in.) of the pool’s edge, such as slide legs or non-removable handrails, these measurements are taken as the ‘A’ and ‘B’ measurements are being done, and recorded as, for example, slide leg point ‘AA1,’ slide leg point ‘BB1,’ slide second leg point ‘AA2,’ slide second leg point ‘BB2,’ etc. These measurements will identify areas of the safety cover where cutouts are necessary. Some cover manufacturers provide measurement sheets which provide space to list point ‘1’ and point ‘2’ for specific obstructions, or for changes in deck material or height.

Water features, rock walls, or gardens that are close to the edge of the pool need to have their size, location, and proximity to the pool edge noted in the measurements. The cover needs to be made to fit these obstructions; therefore, providing the manufacturer with drawings or photos is also helpful. In these instances, rather than using cables to secure the cover, the installer should consider requesting that ‘D’ loops be attached to the cover, as they can be directly fastened to the obstruction (e.g. a poolside waterfall/rock wall).

The installer should also indicate areas where the deck is less than 0.3 m (3 ft) wide, so the cover manufacturer knows to supply shorter springs or garden stakes. Some manufacturers offer software, which allows installers to input the ‘A-B’ measurements and view a diagram to check for accuracy.