The pool installer curriculum

By Melissa Brown and Peter Brown

Education and training are integral components for those in the pool industry who strive to be the best in the business. For far too long, the approach most pool builders took was the in-house, transfer-of-knowledge/on-the-job-training style of teaching. While this can be an easy and effective way to train new staff, it rarely explores creative new practices and methods. Instead, it often perpetuates existing bad habits and does nothing to advance the professionalism of the industry as a whole. It is encouraging to see the tide seems to be shifting, as a real interest in industry standard training and certification programs is beginning to take hold.

Starting in 2014, under the leadership of Dave Simek, Dave Warren, Rodney Taylor, and Mark Fournier, the Pool & Hot Tub Council of Canada (PHTCC) established a renewed focus on industry education and certification programs for its members. In the span of a few years, a number of new programs were developed, existing courses were drastically revamped, and a database of online industry training modules was created. A two-tiered Industry Trade Certification Program was concurrently implemented, and the results have been positive. The PHTCC has seen interest in its training resources steadily increase, and the numbers of registrants for the various courses offered at the Canadian Pool & Spa Conference & Expo gets larger each year. Participation in the ‘Pool Installation 101’ and ‘Pool Installation 201’ courses offered at last year’s show in Niagara Falls, Ont., exemplifies this new dynamic.

Rebuilt from the ground up

In 2016, the pool installation courses were completely redeveloped by the authors—the brother-sister ownership team at BonaVista Pools Ltd., in Markham, Ont. Together they used their combined 40-plus year experience of shared pool building and project management knowledge to design course material based on the active principles used in their business. They also brought a unique perspective to the table on what pool business owners would want their employees to take away from such programs.

The opportunity the ‘Pool Installation 101’ course provided was a means to introduce new employees into the industry. ‘Pool Installation 201’ focuses more on project management specifics. As the course content took shape, the authors worked to ensure there would be plenty of room for active discussion during the delivery of the key learning objectives. Participants found the program’s built-in encouragement for guided audience to be the most rewarding.

Pool Installation 101

This three-hour PHTCC short course introduces pool installation processes and the numerous options, choices, and points of differentiation available in the industry. It covers the following topics: circulation systems, pool types, filtration, heating options, sanitization, plumbing, options and inclusions, services, pool covers, contracts, client relations, and project management basics.

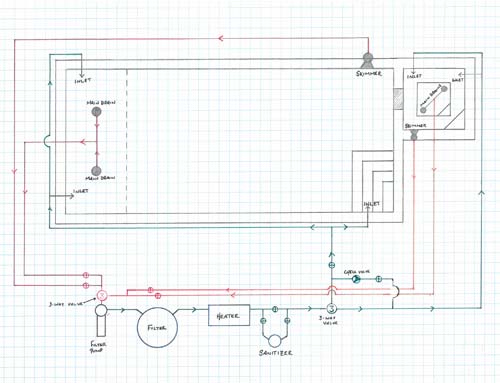

Circulation systems

This is paramount for every pool, regardless of the type of construction or choice of component. It is vital for anyone involved in the pool industry to understand the various elements of a basic circulation system, the correct placement and ordering of each element in that system, and how water travels through it. Using flow charts and drawing plans, the circulation system of a simple pool, and a pool/hot tub combination are explained in detail.

Pool types

The general attributes, along with the pros and cons, of the four main pool types available in the Canadian market are discussed, including fibreglass, vinyl, shotcrete/gunite, and insulated concrete form (ICF) block.

Filtration

The three most common filtration options are outlined. Discussion centres on the filtration efficiency, media cleaning processes, lifespan, and user-friendliness of sand, cartridge, and diatomaceous earth (DE) filters.

Heaters

A number of different heating options for pools are presented, along with the pros and cons of each. The impact on project planning each option demands, such as energy supply (e.g. gas, propane, or electricity supply), as well as ventilation and clearance considerations, are also discussed. Specifically, the course focuses on the following heaters: direct-fired, electric, heat pumps, solar, and wood-fired.

Sanitization

The need for a sanitization system is explained, and the different choices for addressing bacteria and algae are itemized. The benefits and drawbacks of the most common sanitizers, such as chlorine/bromine, ionizers, ozone, ultraviolet (UV), and hydroxyl are outline, while salt chlorine generators are also explained.