A look into the effectiveness of below-ground solar heating systems

For a pedestal mounted system, the paver installer will set the pedestals to the correct height. Following this, the panel installer will place the panel rows on top of the pedestals and adjust them accordingly. The landscaper then places the pavers on top of the panel.

An on-grade system follows a similar installation schematic. First, the landscaper will prepare the ground surface (sub-base) for typical paver installation (keeping in mind the height differential due to the hydronic system). Then, the panels are set, connected, and tested by the contracted installer.

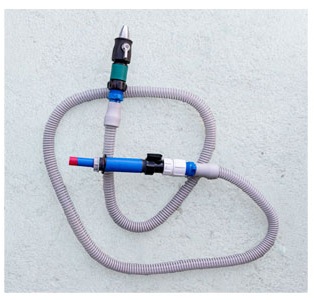

Setting the panels is easy, as they are delivered in factory connected and labelled rows. The installer simply unfolds and sets the panels in place, where they can be adjusted accordingly. Once the panel system is placed on the sub-base, tested, and connected to the manifolds, the paver installer can add bedding sand and continue with the installation of the hardscaping (i.e. pavers, stones, or brick).

The installation process is very similar to how tube- based snowmelt systems are set-up. However, because each row of a below-ground hydronic system is custom-made to the plan’s specifications, laying out the rows and making the connections is faster and simpler. For instance, installing a panel system on a driveway can typically be completed in a half-day, while a tubing installation, on the other hand, may take a couple of days.

On-grade installations are required to have a sub-base approved by the Interlocking Concrete Pavement Institute (ICPI). The sub-base should comprise a thin, 6.4-mm (0.25-in.) layer of sand on top of the base to fill any voids in the rough base material. A panel system provides structure to the base (acting as a second sub-base) and adds full support to the paver array. It is advisable to pre-compact the sand into the joints and crevices between the panels. This can be completed using a vibrating plate compactor that has a plastic base or a hand tamp.

An advantage to the panel system is installations remain within ICPI guidelines. The panel acts as a second sub- base, allowing for a very thin layer of sand over top of the system. Installing tube systems entails adding a layer of sand that is outside of the guidelines, meaning the pavers will no longer be covered under warranty. This is a major issue, as tubing systems often cause settling, or cracking and spalling due to uneven heating.

Full integration

When using a grate-type support system mounted on a wood-framed deck or pedestals, any size paver, brick or stone, can be applied over top.

Wood-framed decks can also be configured to support hydronic panels with just the framing and deck planks, while polyvinyl chloride (PVC) or other synthetic decking can be applied over the panels and fastened to the framing located between the panels.

Adding a new dimension to design

Below-ground solar heaters, patio coolers, and snow melting systems add a new dimension to any space. By supplying designers and architects with a tool that increases the functionality of a landscaped area, extends the season, or otherwise makes a space more useful, the designers are able to incorporate more into the area.

Hardscape professionals are capable of integrating this system with any surface—nothing hinders the design—creating endless opportunities for use in residential/commercial projects. In fact, homeowners and/or commercial property owners can find new uses for their spaces, while being more energy conscious and saving money in the long run.