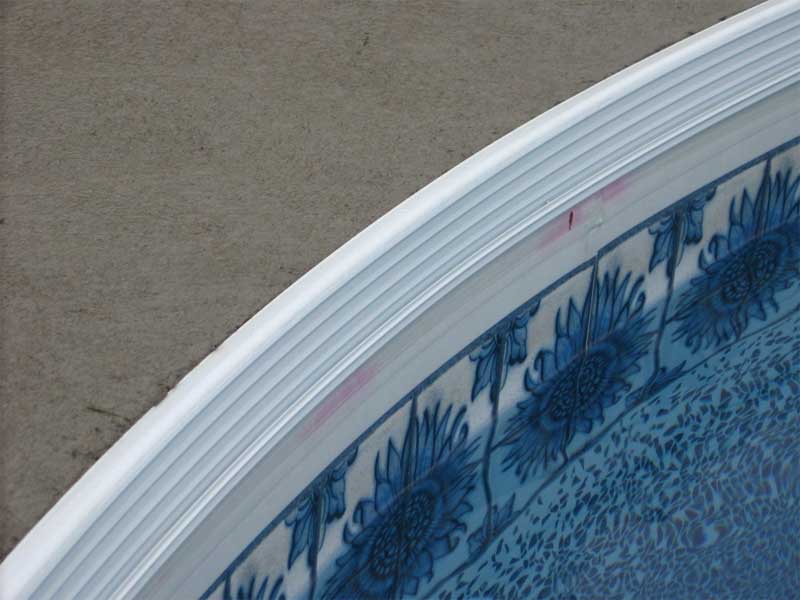

Pink stains

Pink blotches can appear on pool liners of all colours. This type of staining is mainly caused by an indelible pink dye excreted from bacterial micro-organisms. The dye is highly soluble in the plasticizers used in vinyl liners; therefore, it can easily migrate through the entire thickness of the liner.

The dye on the surface can be bleached using chlorine; however, more can migrate back to the surface. If the liner is replaced, all contaminated materials must be removed and the entire pool shell (floor and walls) must be disinfected using a liquid chlorine spray or other suitable disinfectant.

A barrier layer (e.g. plastic sheet or coating of some kind) should be applied directly to the pool shell.

Pool tar

Sticky substances, referred to as ‘pool tar,’ can coat parts of vinyl liners. This is caused by an interaction of quaternary ammonium compounds (quats) used in some algaecides. Decaying organic material, such as leaves, grass, and insects, is another cause. To help prevent this type of staining from occurring, always dilute algaecides before using and wait 24 hours before shocking the pool.

Chemical staining

Any chemical can damage a pool liner if it is not circulated sufficiently. For example, chlorine can settle in the pool’s deep end and bleach the liner without proper circulation.

White, turquoise, light blue, and grey vinyl liners are less likely to show the effects of chlorine bleaching; however, medium or darker blue liner designs will show bleaching immediately.

Pool liners exposed to high concentrations of trichloroisocyanurate-stabilized chlorine can easily cause bleaching in as little as six to 24 hours. As a rule of thumb, all chemicals should be diluted in a bucket of water before adding it into the pool’s deep end. Administer chemicals into the pool in front of a return line to achieve the best dispersion.

Organic debris left on vinyl surfaces can also cause staining and bleaching. This happens after the pool is closed and debris accumulates over several months. When opening a pool, debris should not be allowed to remain on the liner for a long period, especially in the corners. Should a stain occur, citric acid stain lifters can be effective at removing organic stains.

Wrinkling and stretching

Wrinkles in properly-sized vinyl pool liners develop as it absorbs water. Excessive water absorption is a result of high levels of chlorine or bromine. If sanitizer levels are allowed to remain five times higher than normal, an excessive amount of water can be absorbed. Therefore, proper water chemistry is essential to maintain the liner’s integrity. Wrinkling, on the other hand, is caused by changes in the liner stability due to an acidic environment. Large, single doses of hydrochloric (muriatic) acid can damage a vinyl liner.

To avoid stretching and wrinkling, chlorine levels should not remain higher than three ppm for an extended period. Bromine levels should not exceed four ppm. Peak chlorine levels after super-chlorination (between five and 10 ppm), should return to a level between two and three ppm via natural dissipation.

The pool water’s pH must be maintained at the highest practicable level (between 7.4 and 7.8 is desirable). Acidic levels (below seven) must be avoided. To minimize pH fluctuation, total alkalinity should be controlled between 100 and 150 ppm.

How can liner staining be prevented when the pool is closed?

The most important step to preventing any stain causing debris from entering and staying on the vinyl liner for any length of time is to cover the pool when it is closed for the season.

A cover that seals around the pool’s perimeter should be used to prevent the accumulation of organic debris such as leaves and insects. There are closing kits for vinyl pools that include chlorine shock, algaecide, and a metal sequestering treatment. When opening pools, they should be thoroughly cleaned of any debris and the water should be tested for balance and phosphates.

An enzyme-based start-up product can help deal with non-living contaminants along with bringing the sanitizer level back up to operating levels. Proper closing and start-up techniques can ensure a clean and stain-free vinyl liner throughout the season.

Terry Arko has more than 40 years of experience in the pool, spa and hot tub industry, working in service, repair, retail sales, chemical manufacturing, and product development. He is a certified pool operator (CPO) instructor through the National Swimming Pool Foundation (NSPF). He also serves as instructor for the Pool Chemistry Training Institute (PCTI) to certify residential pool techs. Arko is an active member on the Association of Pool and Spa Professionals (APSP) Recreational Water Quality Committee (RWQC). He is a member of Pool & Spa Marketing‘s Editorial Advisory Committee and currently serves as a water specialist for NC Brands, parent company of SeaKlear, Natural Chemistry and Coral Seas. He can be reached via e-mail at tarko@ncbrands.com.

Terry Arko has more than 40 years of experience in the pool, spa and hot tub industry, working in service, repair, retail sales, chemical manufacturing, and product development. He is a certified pool operator (CPO) instructor through the National Swimming Pool Foundation (NSPF). He also serves as instructor for the Pool Chemistry Training Institute (PCTI) to certify residential pool techs. Arko is an active member on the Association of Pool and Spa Professionals (APSP) Recreational Water Quality Committee (RWQC). He is a member of Pool & Spa Marketing‘s Editorial Advisory Committee and currently serves as a water specialist for NC Brands, parent company of SeaKlear, Natural Chemistry and Coral Seas. He can be reached via e-mail at tarko@ncbrands.com.