Sound frame of mind

The structural aluminum frame’s design must meet local building code specifications and be able to withstand snow, wind, and seismic loads. Each aluminum frame requirement is different because climate conditions determine the local design loads. For example, a waterpark or pool enclosure at a ski resort with high snow loads will require an aluminum frame comprising more metal as would an enclosure located along an ocean coast with hurricane force winds versus a facility being built in a southern locale where none of these conditions exist.

However, no matter the local design loads, all aluminum frame enclosures are built in accordance with a minimum L/180 deflection limit which controls how much a frame will deflect when under full design load (i.e. a combination of dead load [weight of the structure] along with snow, wind, and seismic loads). Aluminum frames built to a lesser deflection limit (e.g. the higher the number under the ‘L,’ the less a frame will deflect or bend), might not collapse, but will incur more movement causing gaps between frame and doors and, if enough deflection occurs in the rafters, cause the roof panels to bind in the frame and become inoperable. It may also cause fuses to blow in the control box due to electrical overload of the motors.

Structural aluminum frames can be painted any colour to blend in seamlessly with the surrounding environment. Further, as the structural frame is naturally rust and corrosion-proof it is ideal for indoor aquatic facilities that are regularly exposed to pool chemicals, indoor/outdoor atmospheres, and wet environments.

More than just window dressing

Strong, durable glazing materials are also an integral part of the retractable enclosure design, as they allow open views of the exterior surroundings with minimal obstruction—even when the structure is closed. As mentioned earlier, a range of materials can be used depending on the design requirements.

Multi-walled polycarbonate panels, in particular, have become the preferred material for this type of retractable enclosure design as it offers several structural advantages. For instance, in comparison to glass, lightweight polycarbonate allows for less structural support, while the multi-walled design offers high thermal resistance, great insulating properties, and ultraviolet (UV) protection.

When the roof is open, it creates a chimney effect which allows moisture and chloramines created by pool chemicals to escape. This ventilation also reduces the need for dehumidification and air filtration systems, as well as air conditioning during the summer. By combining this air circulation with the natural light of the all-glazed envelope, aquatic facilities with a retractable enclosure also use less energy when it comes to lighting and HVAC systems. Managers at some venues where a retractable enclosure has been installed have seen a 20 per cent reduction in energy use in comparison to a conventional aquatic facility of similar size.

Structures that defy conventions

Rigorous engineering and design make retractable enclosures durable and reliable, but creativity and innovation are also needed to catch the attention of visitors to make the venue memorable. The easier it is for people to forget a location, the more likely they are to not remember the business.

Effective retractable enclosures create spaces that break down uniformity by blending the indoors with the outdoors. The unique experience of these attractions encourages visitors to keep coming back. Moreover, as manufacturing timelines become more sophisticated and customizable, it has become easier for aquatic venues of all sizes to create their own unique retractable enclosure designs with the expertise of a qualified architectural firm.

Using the aluminum frame and glazing method discussed earlier, a retractable enclosure can be fabricated to fit much more versatile specifications than a conventionally built structure. Thanks to their lightweight and exceptional strength, aluminum frames are able to free-span beyond 50 m (165 ft) and more than 91 m (300 ft) with additional support. As a result, facilities equipped with a retractable enclosure provide patrons the feeling of an extremely open space with the roof structure seeming to hang weightless over the venue. The system’s versatility also allows for many custom specifications to be integrated into its design.

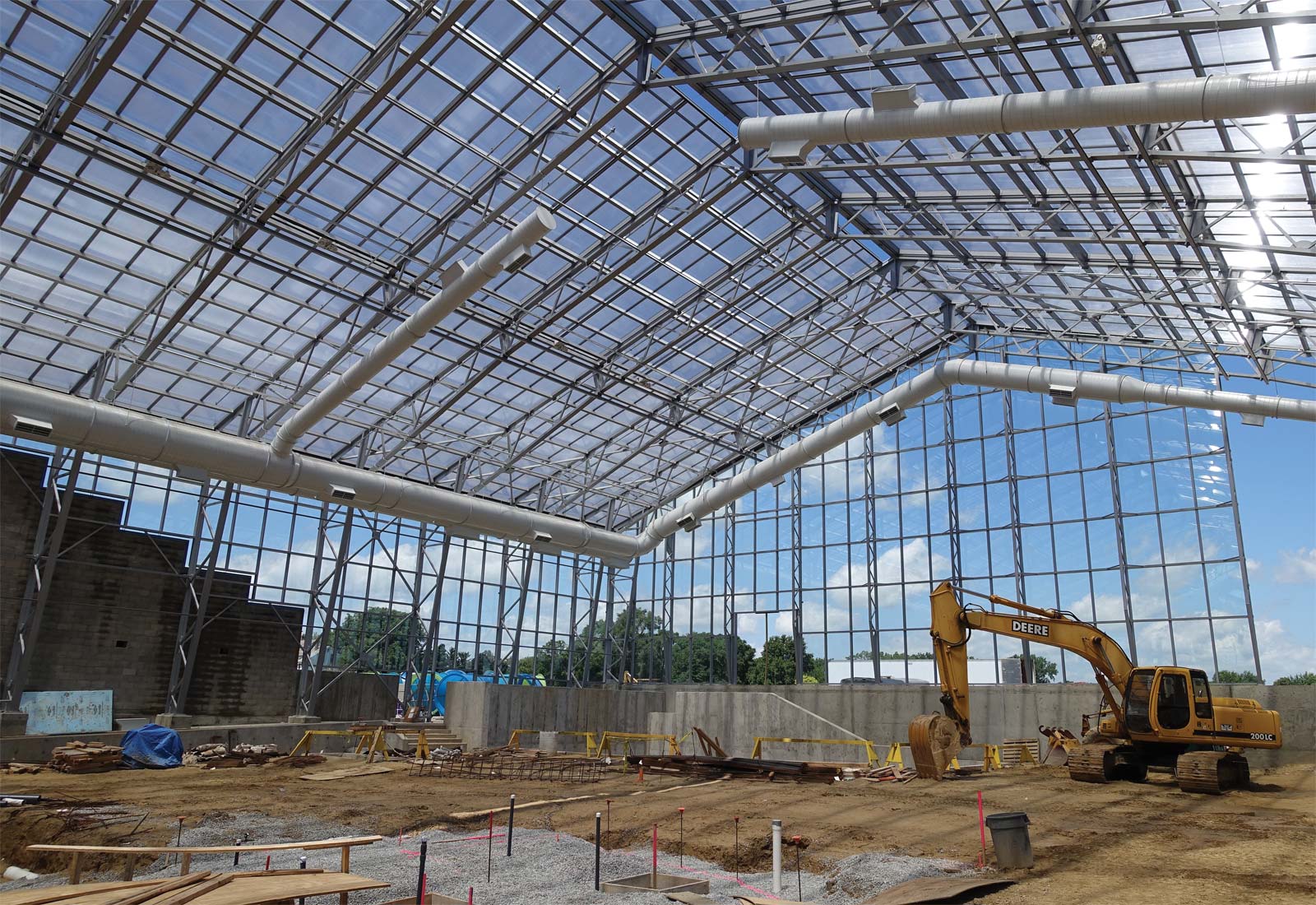

One venue which successfully installed a retractable enclosure was Jay Peak Resort in Jay, Vt., when its owners decided to install a new indoor waterpark called Pump House. Completed in 2015, the waterpark is located in a 4645-m2 (50,000-sf) enclosure with an arching roof made of retracting polycarbonate panels. The structure’s aluminum frame is designed to be unobtrusive, blending in the roof panels with minimal supports. As a result, the Pump House seems to stretch on massively, giving guests the sensation of playing and swimming outdoors. Further, as Jay Peak Resort is located in an area with some of the heaviest snowfalls in the U.S., the roof was engineered to withstand snow loads of 3.8 kPa (80 psf).

The addition of the waterpark and its unique retractable roof was a hit with visitors as the resort experienced a 120 per cent year-over-year growth in guest reservations, as well as a 300 per cent increase in single-day visitors.

Pirate’s Cay waterpark in Sheridan, Ill., (now owned by Holliday Inn’s Orange Lake Club) saw similar success when it opened its own customized, glass-panelled enclosure in 2014. This free-standing, double-sloped enclosure includes two 7.3-m (24-ft) high glass sidewalls and spans 40.2 x 45 m (132 x 148 ft), with two gable ends connecting seamlessly with the main building.

Another example is Zehnder’s Splash Village Hotel and Waterpark in Frankenmuth, Mich. After almost 10 years of successful business, the family-owned waterpark had an enclosure installed which added 2694 m2 (29,000 sf) of aquatic attractions housed under a double-sloped retractable roof. Converting the park into an indoor/outdoor waterpark made it an instant success upon reopening in 2014. The new park design drew in many new visitors in the 2014-15 period, generating more than $2 million in single-day tickets which exceeded the company’s three-year pro forma.

These examples represent only a few cases where an investment in a custom retractable enclosure has led to increased business and attention for an aquatic venue. These structures are not only eye-catching and memorable for users, but also provide peace of mind for many owners thanks to their added benefits.

Built to move

The best retractable enclosure designs include operable panels as an integral part of the structure’s construction. A well-qualified design team will take full advantage of the architectural benefits offered by an aluminum frame and glazed-panel system to create a structure that retracts reliably without creating excessive loads or introducing obtrusive structural features.

The world’s most prominent aquatic facilities with retractable enclosures have been engineered with motorized systems that are custom-built to operate the retractable panels. This process is critical in the structure’s design; the end result is a motorized system that is crafted to accommodate the precise weight, size, and paths of the structure’s components.