Aluminum framing materials offer many advantages for aquatic venues

by jason_cramp | March 28, 2017 8:30 am

By Mark Albertine

[1]

[1]Creating an all-season indoor aquatic attraction, whether it is a pool or waterpark, is a major commitment that requires a great deal of consideration. With this in mind, venue owners can reduce the stress caused by taking on such a venture by carefully choosing the appropriate design and materials at the start of the project.

For aquatic venues in particular, retractable roof designs built with a thermally broken aluminum framing system (a barrier in between the inside and outside window frames that help prevent conductive thermal energy loss) have been advantageous to many owners.

In fact, aquatic facilities built using aluminum-framed retractable roofs have lower energy, maintenance, and operating costs (compared to those built with conventional, fixed-roof structures) thanks to two key factors:

- The ability to use natural lighting and ventilation, which reduces energy costs with respect to illumination as well as heating, ventilation, and air conditioning (HVAC) systems to manage indoor air quality (IAQ).

- Reduced maintenance costs of the retractable enclosure’s aluminum frames, as they are corrosion-resistant.

Retractable roof designs and enclosures can be implemented on a wide range of aquatic venues in many locations and climates around the world. By choosing a design and construction firm with the right experience, venue owners can enjoy the benefits of a unique, quality engineered structure that takes full advantage of its materials. This article will provide an overview of how an aluminum-framed retractable roof enclosure can be designed and built successfully for an aquatic facility.

Diverse team of experts

Whether it is a full-scale family resort that attracts thousands of visitors every year or a local pool providing fun and recreation to a community, every aquatic facility requires a team of dedicated professionals to design and operate it successfully. Even a small-scale pool requires extensive plumbing, water filtration, and drainage systems, not to mention temperature control systems, chemical analysis, and other water engineering services.

Putting all of these features inside a retractable enclosure adds another layer of requirements, as additional HVAC systems, motorized roof components, structural engineering, and many other elements must be in place before a venue can open. It can become a challenge for owners if these things are not completed properly, but when the right team of experts is assembled, the design and construction of an indoor aquatic venue with a retractable enclosure can be extremely rewarding.

To bring together all of the functional components of an aquatic attraction, a building project needs to be managed by a team of professionals who are highly experienced in their fields. This team should meet frequently throughout the project—from start to finish—to ensure everyone understands the goals and vision of the job, as well as to ensure everyone can work seamlessly together, no matter what role he/she plays.

A typical indoor aquatic attraction will include experts from many industries, including:

- Surveyors;

- Zoning and building code specialists;

- Financial consultants;

- Architects;

- Structural engineers;

- Mechanical, electrical, and plumbing (MEP) engineers;

- Water systems engineers; and

- Planning and operations managers.

[2]

[2]To streamline the planning process for venue owners, a good firm will already have experts on staff from all of these professions who are ready to design and build an indoor aquatic park with a retractable enclosure. These firms also provide dedicated project managers for each job, along with a team of in-house architects, engineers and suppliers who are capable of custom designing and fabricating a retractable enclosure.

The team starts by consulting with the venue owners and managers to determine the project’s precise goals and specifications through the stages of concept, schematic design, design/development and, finally, construction/shop drawings. As soon as the shop drawings for an enclosure have been approved, the project manager starts the production process, including fabrication sheets for each and every component that will be fabricated for the retractable enclosure. During this process, the project manager and fabrication team can take advantage of 3D design software to model and test each component virtually before sending them to the production line. Once a design reaches the manufacturing centre, the fabrication process can be completed quickly and precisely using advanced computer numeric control (CNC) machining tools. A CNC machine then fabricates the design in aluminum alloys, performing routing, drilling, tapping, thread milling, notching, sawing, and many other operations efficiently and economically. Afterwards, professional welders who are specifically trained and certified to work with aluminum weld the components together to complete the assembly.

Once the structure’s components are built and have passed inspection, they are shipped to the building site. Here, an experienced team of installers assemble each component according to the approved shop drawings. The result is a fast and highly accurate installation process that keeps the project on schedule.

Throughout the design, engineering, and manufacturing processes, quality control professionals, third-party inspectors, independent welding engineer consultants, and other professional inspectors ensure all components are compliant with local and international standards. If the construction team includes experienced, skilled installers, a project can be completed on schedule. Further, facility owners can be assured the retractable enclosure will fit the project specifications precisely.

Quality design and engineering

[3]

[3]Aquatic facility enclosures with retractable roofs are built with materials to meet today’s architectural standards. To make a client’s retractable roof structure a reality, architects rely on a proven, effective design and construction technique. This involves the use of non-ferrous thermally broken aluminum for framing structures; glazing consisting of polycarbonate (PC), insulated glass, or ethylene tetrafluoroethylene (ETFE), custom motorized roof components; and other design and fabrication technologies that can be adapted for almost any location or climate. These specialized design and engineering methods have not only produced some of the world’s most impressive structures for aquatic venues, they have often done so with lower-maintenance costs than the industry average.

The heart of the design is a thermally broken aluminum frame. This material offers many benefits over traditional steel construction: it is lighter in weight and can be easily shaped for custom designs, yet it offers comparable strength and durability. These properties reduce the load of the enclosure or skylight on existing structures, giving the planning team flexibility when designing projects with long spans for a more expansive atmosphere. Aluminum alloys have been used successfully on retractable enclosures of many sizes—from local pools and recreation centres to some of the world’s largest waterparks.

Thermal breaks within the aluminum frame are important to prevent the transfer of exterior cold air through the frame where it can mix with the warm interior air and form condensation. Exterior metal is separated from the interior metal by a neoprene spacer to form this ‘break.’

While this break is critical for all aluminum frame designs, it is especially important for aquatic facility enclosures due to the warmer than usual atmosphere of an indoor pool. The air temperature in an enclosed pool must be kept two degrees warmer than the water, which creates a greater temperature difference between the inside and outside air temperatures. As such, it is important to not only have a thermally broken aluminum frame, but the entire enclosure envelope should consist of a thermally broken design. Further, an interior and exterior skin separated by a 25-mm (1-in.) thick rigid core should be used to form an insulating panel at all transitions rather than a single piece of sheet metal. Transitional areas include: where the enclosure changes direction from the slope to the vertical at the eave; at a jamb condition from slope to gable end; or against an adjacent structure.

Aluminum alloy 6061 T6 and 6063 T5/T6 are commonly used in the construction of retractable enclosures and skylights as they can be created to meet specifications for many different designs. Pure aluminum is too soft and reactive to be used in architectural applications.

According to industrial standards, aluminum alloys with a numeric code beginning with six possess far greater strength and durability. The ‘T6’ suffix denotes a higher temper (hardness) than average, which is obtained with heat treatment and artificial aging, making the alloy well-suited for commercial architecture. Many metallurgy experts say 6061 T6 aluminum has a high strength-to-weight ratio, “making it ideal for large parts that need to be very light.”[4]

Sound frame of mind

[5]

[5]The structural aluminum frame’s design must meet local building code specifications and be able to withstand snow, wind, and seismic loads. Each aluminum frame requirement is different because climate conditions determine the local design loads. For example, a waterpark or pool enclosure at a ski resort with high snow loads will require an aluminum frame comprising more metal as would an enclosure located along an ocean coast with hurricane force winds versus a facility being built in a southern locale where none of these conditions exist.

However, no matter the local design loads, all aluminum frame enclosures are built in accordance with a minimum L/180 deflection limit which controls how much a frame will deflect when under full design load (i.e. a combination of dead load [weight of the structure] along with snow, wind, and seismic loads). Aluminum frames built to a lesser deflection limit (e.g. the higher the number under the ‘L,’ the less a frame will deflect or bend), might not collapse, but will incur more movement causing gaps between frame and doors and, if enough deflection occurs in the rafters, cause the roof panels to bind in the frame and become inoperable. It may also cause fuses to blow in the control box due to electrical overload of the motors.

Structural aluminum frames can be painted any colour to blend in seamlessly with the surrounding environment. Further, as the structural frame is naturally rust and corrosion-proof it is ideal for indoor aquatic facilities that are regularly exposed to pool chemicals, indoor/outdoor atmospheres, and wet environments.

More than just window dressing

Strong, durable glazing materials are also an integral part of the retractable enclosure design, as they allow open views of the exterior surroundings with minimal obstruction—even when the structure is closed. As mentioned earlier, a range of materials can be used depending on the design requirements.

Multi-walled polycarbonate panels, in particular, have become the preferred material for this type of retractable enclosure design as it offers several structural advantages. For instance, in comparison to glass, lightweight polycarbonate allows for less structural support, while the multi-walled design offers high thermal resistance, great insulating properties, and ultraviolet (UV) protection.

[6]

[6]When the roof is open, it creates a chimney effect which allows moisture and chloramines created by pool chemicals to escape. This ventilation also reduces the need for dehumidification and air filtration systems, as well as air conditioning during the summer. By combining this air circulation with the natural light of the all-glazed envelope, aquatic facilities with a retractable enclosure also use less energy when it comes to lighting and HVAC systems. Managers at some venues where a retractable enclosure has been installed have seen a 20 per cent reduction in energy use in comparison to a conventional aquatic facility of similar size.

Structures that defy conventions

Rigorous engineering and design make retractable enclosures durable and reliable, but creativity and innovation are also needed to catch the attention of visitors to make the venue memorable. The easier it is for people to forget a location, the more likely they are to not remember the business.

Effective retractable enclosures create spaces that break down uniformity by blending the indoors with the outdoors. The unique experience of these attractions encourages visitors to keep coming back. Moreover, as manufacturing timelines become more sophisticated and customizable, it has become easier for aquatic venues of all sizes to create their own unique retractable enclosure designs with the expertise of a qualified architectural firm.

Using the aluminum frame and glazing method discussed earlier, a retractable enclosure can be fabricated to fit much more versatile specifications than a conventionally built structure. Thanks to their lightweight and exceptional strength, aluminum frames are able to free-span beyond 50 m (165 ft) and more than 91 m (300 ft) with additional support. As a result, facilities equipped with a retractable enclosure provide patrons the feeling of an extremely open space with the roof structure seeming to hang weightless over the venue. The system’s versatility also allows for many custom specifications to be integrated into its design.

One venue which successfully installed a retractable enclosure was Jay Peak Resort in Jay, Vt., when its owners decided to install a new indoor waterpark called Pump House. Completed in 2015, the waterpark is located in a 4645-m2 (50,000-sf) enclosure with an arching roof made of retracting polycarbonate panels. The structure’s aluminum frame is designed to be unobtrusive, blending in the roof panels with minimal supports. As a result, the Pump House seems to stretch on massively, giving guests the sensation of playing and swimming outdoors. Further, as Jay Peak Resort is located in an area with some of the heaviest snowfalls in the U.S., the roof was engineered to withstand snow loads of 3.8 kPa (80 psf).

[7]

[7]The addition of the waterpark and its unique retractable roof was a hit with visitors as the resort experienced a 120 per cent year-over-year growth in guest reservations, as well as a 300 per cent increase in single-day visitors.

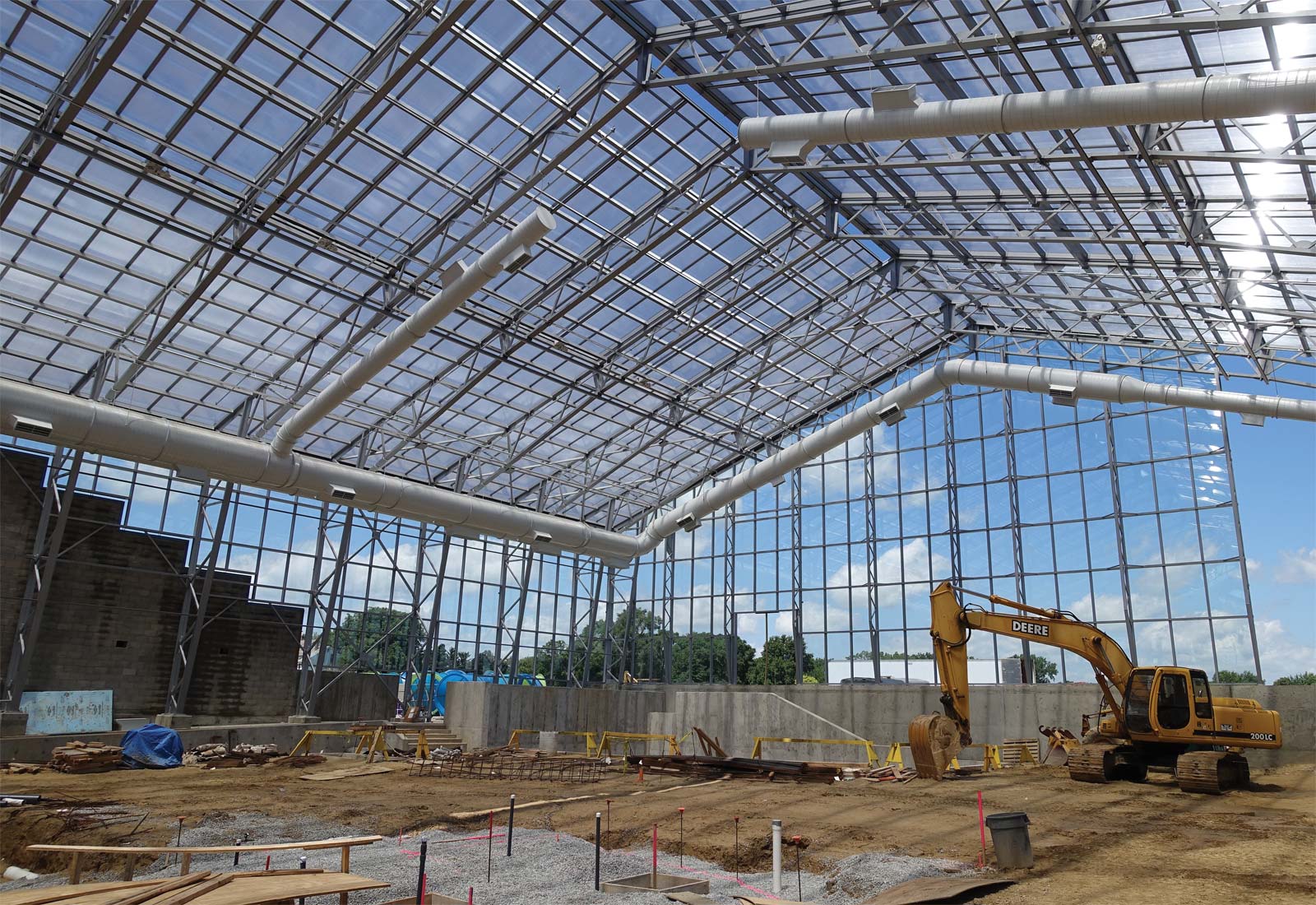

Pirate’s Cay waterpark in Sheridan, Ill., (now owned by Holliday Inn’s Orange Lake Club) saw similar success when it opened its own customized, glass-panelled enclosure in 2014. This free-standing, double-sloped enclosure includes two 7.3-m (24-ft) high glass sidewalls and spans 40.2 x 45 m (132 x 148 ft), with two gable ends connecting seamlessly with the main building.

Another example is Zehnder’s Splash Village Hotel and Waterpark in Frankenmuth, Mich. After almost 10 years of successful business, the family-owned waterpark had an enclosure installed which added 2694 m2 (29,000 sf) of aquatic attractions housed under a double-sloped retractable roof. Converting the park into an indoor/outdoor waterpark made it an instant success upon reopening in 2014. The new park design drew in many new visitors in the 2014-15 period, generating more than $2 million in single-day tickets which exceeded the company’s three-year pro forma.

These examples represent only a few cases where an investment in a custom retractable enclosure has led to increased business and attention for an aquatic venue. These structures are not only eye-catching and memorable for users, but also provide peace of mind for many owners thanks to their added benefits.

Built to move

The best retractable enclosure designs include operable panels as an integral part of the structure’s construction. A well-qualified design team will take full advantage of the architectural benefits offered by an aluminum frame and glazed-panel system to create a structure that retracts reliably without creating excessive loads or introducing obtrusive structural features.

The world’s most prominent aquatic facilities with retractable enclosures have been engineered with motorized systems that are custom-built to operate the retractable panels. This process is critical in the structure’s design; the end result is a motorized system that is crafted to accommodate the precise weight, size, and paths of the structure’s components.

[8]

[8]Large and small retractable enclosures are able to operate with great speed and reliability. Aqua Sferra waterpark in Donetsk, Ukraine, for example, is housed in the world’s largest free-standing aluminum dome (standing 26 m [85 ft] high and 85 m [279 ft] in diameter).

The dome’s design uses 16 custom-built and calibrated motors to move four triangular roof panels (each measuring 24.3 m [80 ft] across the base and 24.3 m [80 ft] across the arch) along 587 m (1926 ft) of track to open the park to the outdoors.

Despite the weight and size of the four panels, the system is able to retract in less than 10 minutes. This speed allows park operators to minimize delays due to inclement weather, while also giving the park an extremely dynamic and open atmosphere that guests will remember.

The customized nature of the design and materials used to fabricate these enclosures allows each component to be tailored to meet the particular requirements of each venue’s location. Further, the retractable panels and support profiles are also fabricated to fit precisely when closed to prevent drafts.

Increasing in popularity

The use of aluminum framed retractable enclosures for aquatic venues is becoming increasingly popular among developers. The lightweight, adaptability, and natural corrosion-resistance of the support materials, along with the design possibilities the transparent glazing offers, make these enclosure systems well-suited for these facilities.

With many successful installations worldwide, the abundance of structural and design advantages retractable enclosures offer have made these systems a desirable choice for aquatic venues of all types. Facility owners can make the most of these materials and design techniques by seeking an experienced, well-equipped firm that specializes in these projects.

[9]Mark Albertine has nearly 30 years’ experience in all facets of the aluminum and glass construction industry. In 1989, shortly after completing university, Albertine founded OpenAire, a firm that designs and constructs unique retractable roof structures and skylights. As president, his company has developed custom retractable enclosure and operable roof systems for a number of applications all over the world. He can be reached via e-mail at mark@openaire.com[10].

[9]Mark Albertine has nearly 30 years’ experience in all facets of the aluminum and glass construction industry. In 1989, shortly after completing university, Albertine founded OpenAire, a firm that designs and constructs unique retractable roof structures and skylights. As president, his company has developed custom retractable enclosure and operable roof systems for a number of applications all over the world. He can be reached via e-mail at mark@openaire.com[10].

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xPiratesCay_int_OpenAire.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xPiratesCay_ext_OpenAire.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xManufacturing_Zehnders_2_O.jpg

- “making it ideal for large parts that need to be very light.”: http://www.sapagroup.com/en/na/profiles/6061-t6-aluminum-properties/

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xZehnders_Splash_build_Open.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xJayPeak_PumpHouse_int_Open.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xJayPeak_PumpHouse_ext_Open.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/xAquaSferra_roof_OpenAire.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2017/03/AlbertineHeadshot.jpg

- mark@openaire.com: mailto:mark@openaire.com

Source URL: https://www.poolspamarketing.com/trade/aluminum-framing-materials-offer-many-advantages-for-aquatic-venues/