An energy-efficient heating and cooling method for indoor pools

by Sally Bouorm | October 1, 2010 2:55 pm

[1]

[1]By Steve Hamoen

Given the seasonal shifts in the Canadian climate, indoor pools are a luxurious, value-added item for a homeowner, offering fitness and recreational enjoyment 365 days a year. For the heating, ventilation and air conditioning (HVAC) industry, indoor pool environments pose a unique challenge in terms of humidity control and its associated costs. While commercially packaged humidity units have their strengths, there are tremendous gains to be made in leveraging hydronic and geothermal technology to satisfy consumer demand for energy-efficient indoor pool design.

Dehumidification units for commercial pools

Commercially available humidity control packaged units for an indoor pool environment have existed for a long time and typically satisfy the following conditions:

- Space heating/cooling;

- Dehumidifying; and

- Pool water heating.

While these units are efficient, they tend to function best when responding to multiple conditions in the indoor pool environment, such as calls for space cooling and dehumidification or pool heating and dehumidification. Energy is shared as pool dehumidifiers extract heat from the air in the room to cool or dehumidify it, and then transfer the ‘free’ recovered heat to the pool water or to supplement space heating. Moisture captured on the air coil returns to the pool, leaving a comfortable living environment indoors.

In circumstances where only one or two conditions in the room need to be met (e.g. when the unit recognizes the water temperature is adequate, but the room needs to be cooler or the humidity  [2]controlled), the system will typically respond like a traditional air conditioning unit. In this instance, it will start transferring heat in the air to an outdoor condenser. While this works, it is not the most efficient way to use the energy, particularly in a climate where daily temperature swings can mean heat might be needed later in the evening. This is where hydronic systems can dramatically impact HVAC design in indoor pools.

[2]controlled), the system will typically respond like a traditional air conditioning unit. In this instance, it will start transferring heat in the air to an outdoor condenser. While this works, it is not the most efficient way to use the energy, particularly in a climate where daily temperature swings can mean heat might be needed later in the evening. This is where hydronic systems can dramatically impact HVAC design in indoor pools.

Hydronic systems

The term ‘hydronic’ refers to using liquid, such as water, as the mechanism for heat transfer in heating and cooling systems. Its greatest asset is the flexibility it offers—heating can be created from any source (e.g. a boiler, geothermal, electric, wood, solar, etc.) or redistributed from another source that is trying to reject heat, such as a cooling process.

Rather than reject heat from an indoor space via an outdoor condenser, to cool down the room, as noted in the earlier example, the heat can be sent via a hydronic system to a ‘buffer’ tank as warm water, which can be used in other processes. Secondary processes that can benefit from consumption of this relatively ‘free’ heat include floor warming, preheating domestic water, spa heating or hydronic forced-air heating elsewhere in the building. Once the tank capacity is maximized, the heat is then directed elsewhere (e.g. to a water feature, outdoor chill tower or condenser, sprinkler system or geothermal system).

Geothermal systems

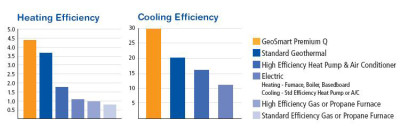

Geothermal or ground source heat pumps (GSHPs) use the earth’s relatively constant temperature to heat or cool an indoor pool, home or business. This system typically uses the earth’s crust as a thermal mass from which constant energy can be drawn. As the earth is heated by solar energy, a properly designed and installed geothermal system has little or no overall earth temperature impact to the area in which it is installed.

This technology, also known as geo exchange or ground source systems, comprises two major components; the heat pump and the ground loop. The heat pump, simply defined, has a compressor and two heat exchangers and is installed in the building. One is connected to the ground to absorb or reject heat, while the second heat exchanger is connected to a load to transfer heat to a load process (i.e. space or pool water heating). The compressor acts as a transfer agent between the two heat exchangers. It takes heat from the heat exchanger that requires heating or cooling and transfers it to the other side via the refrigeration cycle inherent in the heat pump.

The compressor takes heat from the heat exchanger that requires heating or cooling and transfers it to the other side through the use of the refrigeration cycle inherent in the heat pump. The second component is the ground source heat exchanger, which can be implemented in several different ways:

Horizontal loops

[3]This is the most common type of ground source heat exchanger. Horizontal loops are commonly used in rural areas due to the land space needed for installation. An excavator will dig several trenches, roughly 1.8-m (6-ft) deep and 91-m (300-ft) long, where geothermal piping is placed. The trench is then backfilled with the same soil.

[3]This is the most common type of ground source heat exchanger. Horizontal loops are commonly used in rural areas due to the land space needed for installation. An excavator will dig several trenches, roughly 1.8-m (6-ft) deep and 91-m (300-ft) long, where geothermal piping is placed. The trench is then backfilled with the same soil.

Vertical loops

[4]Vertical loops are primarily used in urban areas, as they require little land space for installation. A specially designed geothermal drilling rig bores vertical holes into the ground, each ranging from 55- to 165-m (180- to 540-ft) deep. Geothermal pipe is inserted in each vertical bore and the holes are filled with bentonite grout.

[4]Vertical loops are primarily used in urban areas, as they require little land space for installation. A specially designed geothermal drilling rig bores vertical holes into the ground, each ranging from 55- to 165-m (180- to 540-ft) deep. Geothermal pipe is inserted in each vertical bore and the holes are filled with bentonite grout.

Pond or lake loops

[5]On properties that have a nearby lake or an appropriately-sized pond (at least 2.4 m [8 ft] deep), a loop system can be submerged to rest on the lake/pond bed. A single trench is excavated from the home to the water, and typically, two geothermal pipes are inserted. These two pipes connect to the submerged loop system, which comprise several geothermal pipes.

[5]On properties that have a nearby lake or an appropriately-sized pond (at least 2.4 m [8 ft] deep), a loop system can be submerged to rest on the lake/pond bed. A single trench is excavated from the home to the water, and typically, two geothermal pipes are inserted. These two pipes connect to the submerged loop system, which comprise several geothermal pipes.

Open loops

[6]Open loops are commonly used on rural properties that have existing high-capacity water wells. Ground water is drawn from an aquifer through a supply well and pumped into the heat pump, while discharged water from the pump is redirected into a second well and back into the same aquifer.

[6]Open loops are commonly used on rural properties that have existing high-capacity water wells. Ground water is drawn from an aquifer through a supply well and pumped into the heat pump, while discharged water from the pump is redirected into a second well and back into the same aquifer.

Combining geothermal with hydronic systems

Leveraging existing hydronic and geothermal technology allows installers and homeowners alike to enjoy more eco-friendly, energy-efficient solutions when it comes to indoor pool design, and reap the benefits of more comfortable and better controlled living environments.

The loops (geothermal ground source heat exchangers) carry water or an environmentally friendly antifreeze (hydronics) into the indoor heat pump system to transfer the earth’s natural heating and cooling properties. In the winter, the loops act as a source for heat; in the summer they serve as a place to reject heat.

Geothermal cooling

A geothermal loop is an ideal way to reject excess heat. According to the second law of thermodynamics, heat transfer always occurs from a higher-temperature region to a cooler-temperature region; therefore, heat exchange efficiency is a function of the difference in temperature between the two mediums (i.e. the movement of heat from one place to another). From an efficiency standpoint, rejecting heat to a geothermal system buried in the ground, where the average temperature is normally 10 C (50 F), will be more effective than an outdoor air-cooled condenser with a big blower that is rejecting heat to the hot summer air.

Using the process heat pump, as noted above, leverages the flexibility of energy-efficient hydronic systems and heat pump technology in indoor pool installations, which can also be implemented in a chill pool system.

A chill pool is a concept that is enjoying a revival as an addition to a home spa and/or pool environment. They fit perfectly into an energy-efficient design when used as a source to withdraw heat for other processes. By using the chilling process as a heat source for other systems, such as pool/spa water, energy is again transferred, resulting in potentially significant savings.

Geothermal heating

Using a geothermal loop system in tandem with a pool dehumidification system offers considerable options on the heating side as well. Using a heat pump in conjunction with the ground loop generates returns on the loop investment and delivers added value all year round. A properly designed and installed geothermal heating and cooling system can completely replace other heating alternatives, as it can efficiently generate heat up to 43 to 46 C (110 to 115 F).

Geothermal and hydronic system design parameters

The two design factors critical to maximizing energy efficiency are load temperature and source temperature.

The load temperature is the temperature required in the distribution system for services such as floor warming, space or pool water heating. The load supply water temperature (LSWT) and load leaving water temperature (LLWT) are measured as the load liquid enters and leaves the heat pump on the load side.

The source temperature is the temperature of the liquid flowing through the ground source side. The source entry water temperature (SEWT) and source leaving water temperature (SLWT) are measured as they enter and leave the heat pump on the source or groundside.

The amount of energy delivered can be calculated by considering the load and source temperature differences, together with the flow of the liquids measured in litres/gallons per minute (lpm/gpm).

In heating mode, the coefficient of performance (COP) is highest when the geothermal system has to generate a low LSWT, and the SEWT from the ground loop is high. For example, if a floor-warming system requires 26 C (80 F) LSWT to heat a pool deck and the liquid from the ground is 10 C (50 F) SEWT, this heat pump system will out perform a unit requiring 49 C (120 F) LSWT for a low cubic feet per minute (cfm) fan coil when the liquid from the ground is –1 C (30 F) SEWT.

In fact, the most efficient way to heat an occupied space is by floor warming utilizing a well-designed geothermal heating source because of the low approach temperatures and large surface area used to deliver heating energy to where it is needed most.

| HYDRONIC AND GEOTHERMAL CONCEPTS IN ACTION |

|---|

| The following factors were considered to provide an elegant ‘green’ solution for a residential indoor swimming pool installation in Halton Hills, Ont.: • Converting the residential heating system from propane to geothermal heating/cooling; • A closed-circuit indoor swimming pool dehumidifier and pool water heater; • A heat recovery ventilator designed for indoor swimming pools; • A geothermal heat pump, to provide water heating/cooling; • A process heat pump, to provide simultaneous water heating/cooling; • A high-efficiency modulating heating boiler, to provide back-up heating; • Buffer tanks for heating and cooling water; • An indirect hot water tank for domestic use in the indoor pool addition; and • Distribution systems designed to utilize low-grade (low load supply water temperature [LSWT]) and ‘free’ heating sources, such as pool room floor warming, under-pool water heating, large, air heating/cooling coils for the pool room, a domestic hot water preheat tank for the residence and a hot water (excess energy recovery) preheat tank.The integrated project design used the concepts described herein to minimize energy use in an environment that included high humidity and extreme solar loads, large exterior glass surfaces and a variety of heating and cooling demands. For more on this project, see article on page 6. |

Steve Hamoen is the founder and acting president of Zonelife Inc., a contracting and design firm specializing in custom hydronic and geothermal systems for residential and commercial applications in Cambridge, Ont. Hamoen can be reached through his blog at www.geothermalinstallers.ca[7], or by e-mail at steve@zonelife.ca[8].

Steve Hamoen is the founder and acting president of Zonelife Inc., a contracting and design firm specializing in custom hydronic and geothermal systems for residential and commercial applications in Cambridge, Ont. Hamoen can be reached through his blog at www.geothermalinstallers.ca[7], or by e-mail at steve@zonelife.ca[8].

- [Image]: http://poolspamarketing.com/wp-content/uploads/2010/10/IMG_1058.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/Geosmart-Premium-Q-chart.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/Horizontal_Loop.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/Vertical_Loop.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/Pond_Lake_Loop.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/Open_Loop.jpg

- www.geothermalinstallers.ca: http://www.geothermalinstallers.ca

- steve@zonelife.ca: mailto:steve@zonelife.ca

Source URL: https://www.poolspamarketing.com/trade/an-energy-efficient-heating-and-cooling-method-for-indoor-pools/