Best practices for installing interlocking concrete pavers

Selecting paving stones

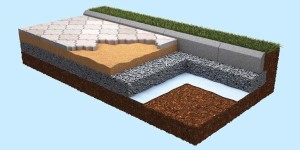

Understanding how ICP systems function is an important part of proper installation. When planning the installation, the overall environment and the strength of the underlying soil subgrade should be considered.

ICPs can last 40 to 50 years and because of this it adds a sizeable amount of value to the client’s home. Further, they also allow the homeowner to co-ordinate and customize activity space, including driveways, walkways, patios, pool decks, and gardens in a way that was never before possible.

The number of consumers selecting ICPs for residential applications has grown rapidly. There are an increasing number of published reports by experts which rate ICPs as the best value for the money by a considerable margin over traditional pavements. In fact, many consumers learn the surprising truth about their landscaping when they put their home up for sale. Further, when landscaping elements are properly installed and maintained, they have a significant long-term influence on the market value of the property.

Base basics

A compacted aggregate base is essential to the proper installation of ICPs. Some of the most common questions and answers with regards to installing this base include:

Q. What is the base?

A.The base is made from stone crushed at a quarry and generally ranges in size from 19 mm (0.75 in.) to very small particles called ‘fines.’ It is graded or sorted after crushing by placing it on screens of different sizes mixed together in various proportions to create a range of particle sizes. The range creates a dense material when compacted.

Q. What is the right mix of particle sizes?

A.Crushed rock normally used under asphalt driveways and roads is generally acceptable under concrete pavers and bedding sand. The mix of particle sizes is often set by provincial or city standards. These materials can be used under patios, driveways, and streets. For example, granular ‘A’ base is commonly used in Ontario.

Q. Where is the base placed?

A.The compacted aggregate base is placed on top of the compacted soil subgrade.

Q. How much base should be used?

A.For patios and walkways, a minimum compacted thickness of 100 to 150 mm (4 to 6 in.) should be used, while for driveways the minimum compacted thickness is 150 to 200 mm (6 to 7.8 in.).

Q. How is it installed?

A.The aggregate base should be installed in compacted layers of approximately 50 to 75 mm (2 to 3 in.).

Q. What type of equipment is required to compact aggregate base material?

A.For patios and walkways, a five‑horsepower (hp) plate compactor will do the job. The plate compactor should have at least 18 to 22 kN centrifugal force (4046 to 4945 pound force [lbf]). For driveways, a large, high-frequency plate rammer or vibratory roller can be used. A walk-behind or ride‑on roller can also be used.

Q. What about maintaining the slope or grade for drainage?

A.Slope the base away from buildings for drainage to remove rain and snow. Walkways and driveways should also slope to remove water. Maintain a slope while keeping a consistent thickness throughout the base by using string lines tied to stakes. Set the lines to mark the final grade. Check depth measurements along the string lines when excavating the pavers.