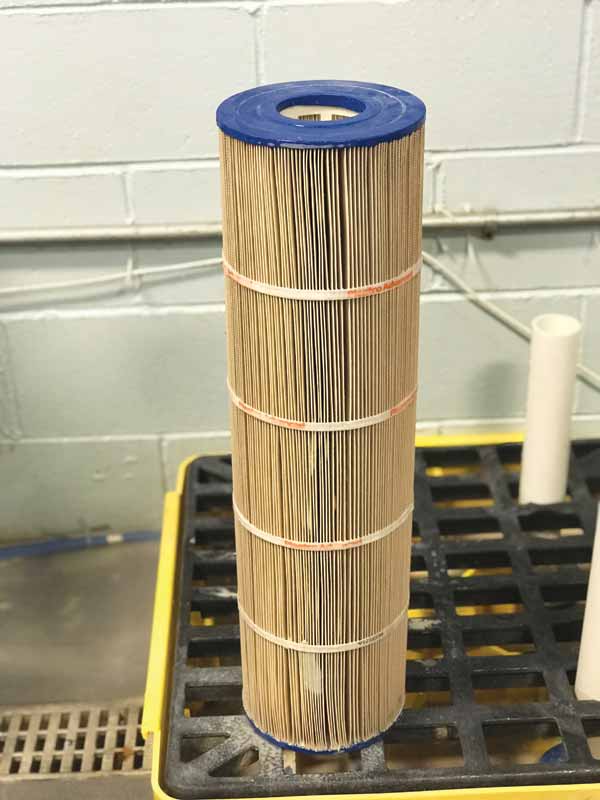

A microscopic look at how the pool environment affects cartridge filters

How to clean a cartridge filter

How are cartridge filters cleaned? This is a popular question with multiple answers, as it depends on what is being cleaned. In most cases, a combination of a weak acid, oxidizer, surfactant, and degreaser will tidy up most dirty filters.

It is a good idea to refrain from using a strong acid to clean a filter, as they can bleach out the product to look as though they are as good as new. However, a strong acid can negatively influence the fibres and, as a result, the filtration performance. It is also recognized that certain treatments and chemicals added to the pool may have non-reversible impact on the filter and may shorten the life of a filter.

The field experiment

With help from Rich Tarricone of Aquatic Pool Systems in Florida, the 2010 Perfect Pool Guy winner, the authors were able to conduct a brief study on filters used in pools located in Florida. It looked at how certain pool conditions, and the chemicals used in the treatment of that condition, affected the filter fabric at a microscopic level.

The images showcase what happens to a cartridge filter under different conditions, including:

- Using clarifiers to increase filter efficiency by capturing finer particles.

Clarifiers are used to increase the filtration efficiency; however, they can become difficult to clean, resulting in reduced life of the filter.

A gel-like substance is formed and, over time, led with debris from the pool, it adheres to the fibres. - Using phosphate removers to reduce phosphate levels in pools.

- Using algaecides to treat algae infected pools.

Algae blooms are difficult to treat. The algae fines could be as small as sub-4 microns, which may become trapped in the web of the filter cartridge, and would require a thorough cleaning. It is always recommended to use an older set of filters. - Vacation home/commercial filters, which see many bodily fluids/oils.

Oil and dirt binds over filtration fabric, forming a film, which reduces the filter’s dirt holding capacity and performance lifespan. This mixture is difficult to clean and often requires degreasing chemicals to help remove the oil from the fabric’s surface. - Calcium scaling.

Calcium deposits are difficult to clean from the surface of the filter. It compromises the effective surface area of the filter and its ability to hold debris.

In conclusion

Under normal conditions, cleaning a cartridge filter using a simple garden hose is sufficient to remove a large portion of the filter cake. When using mechanical agitation such as a brush to clean debris, it is important to use care to minimize any damage to the fabric web.

For heavier soils and other conditions where specialty chemicals and filter aids were used, these treatments may affect the service of a filter; therefore, it is important the recommended cartridge cleaning instructions are followed to prevent the calcification of debris on the fabric surface.

Authors’ note: In subsequent articles, the authors will evaluate the impact these treatments have on cartridge filters by studying the permeability of the media.

Richard Medina (left) is the senior vice-president of engineering for Pleatco LLC. A 24-year veteran of the industry, Medina has extensive experience in filtration, moulding, product, and process improvements. He can be reached via e-mail at rmedina@pleatco.com.

Richard Medina (left) is the senior vice-president of engineering for Pleatco LLC. A 24-year veteran of the industry, Medina has extensive experience in filtration, moulding, product, and process improvements. He can be reached via e-mail at rmedina@pleatco.com.

Abhi Pillai is the director of research and product development for Pleatco LLC. In his seven-year tenure, Pillai is specialized in evaluating filtration fabrics and development of new products at Pleatco. He can be reached via e-mail at apillai@pleatco.com.