Cartridge filtration fundamentals

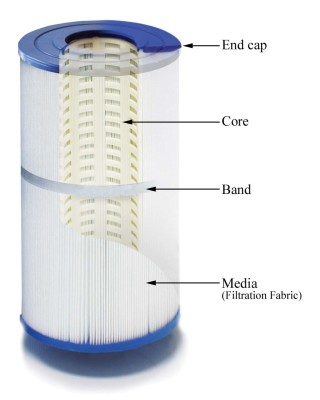

Not all filter cartridges are the same. There are four main elements in an effective cartridge filtration system: the core, media (filtration fabric), bands and end caps.

Core

A properly designed core enhances flow rates, reduces head loss (lost pressure or velocity of a flowing fluid between two points created by friction) and maximizes filtration. This improved flow reduces wear and tear on the pump, uses less energy and extends cartridge life. This becomes even more important given the recent trend of switching to energy-efficient variable-speed pumps. When a pump is on low speed and saving energy, a core that maximizes flow will make it easier for water to move through the filter, maximizing the filtration area and creating uniform flow distribution through the entire cartridge.

In contrast, a poorly designed core will create water channelling, which reduces the usable area of the filter cartridge (i.e. a 9.2-m2 [100-sf] filter will work only as effectively a 4.6-m2 [50-sf] filter). A high-quality filter cartridge with a good core is even more important for larger inground pool applications, where as many as four filter cartridges are installed. In these situations, anywhere from 14 to 18.5 m2 (150 to 200 sf) of filtration fabric is used. In such a complex installation, improper flow distribution greatly decreases usable filtration area, making for an inefficient filtration system.

The consequences of poor flow are significant. Increased pressure will have a negative impact on every component in the filtration system, resulting in early failure. Filtration fabric is the most expensive component of a filter cartridge; if a poorly designed core inhibits the full use of the media, money is wasted.

Media/filtration fabric

Virtually all major filter cartridge manufacturers use the same media—spun-bonded polyester filtration fabric. This media is bonded together by entangling the fibre (filaments) without using adhesives. This material ‘depth loads,’ meaning some particles will actually get imbedded into the fabric and can not be cleaned out, as previously explained. Eventually, the media will become inefficient. In a spa setting, this is indicated when a filter quickly inhibits water flow right after cleaning. In pool applications, a clogged filter can be identified by rapidly increasing tank pressure, indicated on the pressure gauge. If this happens, it is time to replace the filter cartridge.

To function most effectively, filtration fabric must be long-lasting and free of fillers, additives or binders, which could serve as potential contaminants that might leach into the water during filtration. Further, the use of point-bonded material, which is less expensive, will reduce water flow, clog more easily and reduce filter life. This media uses additional adhesives to hold fibres together, which reduces flow (and media efficiency) and usually results in shorter filter cartridge life.

Higher-quality filtration fabrics, while more expensive, are also more resistant to rot and mildew, and will retain their physical characteristics when exposed to most solvents, oils, salt solutions, acids and alkalis. This uniform flow distribution results in even dirt loading, providing cleaner water and longer life. Superior filtration fabric is also easily cleaned and can be re-used several times. Lastly, higher-quality filtration fabrics are more uniform in their construction, which facilitates even water flow and provides more surface area to enhance the filtering process. When the fabric construction is uneven, water will move to the point of least resistance and larger particles will not be captured.

Bands

While they are often overlooked, bands are not used for esthetics—they serve a very valuable purpose. Bands should be tightly secured to each pleat for stability and strength. A properly secured band will help enhance flow, assure more consistent use of all the filtration fabric and increase a filter’s resistance to severe operating conditions. Too often, poorly constructed filters have no bands at all, or ones that fall off easily. Without proper bands, the pleats will actually fold over and the usable area of the filter will be reduced.