Cartridge filtration

by Sally Bouorm | October 1, 2010 8:50 am

By John Antretter

[1]

[1]Although it has been on the market for 30 years, cartridge filtration is a virtual newcomer to the pool and spa market compared to other filtration options. Cartridge filtration is growing across the industry in pool applications, capturing virtually all of the spa and above-ground pool market. The reason for this popularity lies in the advantages of filter cartridges, which are effective, efficient, environmentally advantageous and relatively easy to maintain.

Pool and spa builders and service technicians must learn to balance the costs needed to achieve unnecessary expectations with energy consumption and the expenses associated with increased service. With a better understanding of the advantages cartridge filtration can provide, pool and spa professionals can make an informed decision.

A brief history of filtration

A properly maintained filter will reduce the pressure in a pool or spa’s filtration system, keep water flowing smoothly and reduce the wear and tear on all equipment in the system. There are three different types of pool filtration: sand, diatomaceous earth (DE), and cartridge.

Many older pools have a sand filter, the oldest method of pool filtration. Tried and true, sand filters do a fine job cleaning particles approximately 40 to 60 microns in size, but require costly backwashing to clean the filter. Backwashing for even a few minutes to remove old dirt and debris may result in the use of as much as 1,135 to 1,892 L (300 to 500 gal) of water. Pool professionals overlook the true cost of backwashing. The water being pumped down the drain has been chemically balanced and heated.

While DE filtration is an improvement performance-wise on traditional sand methods, it still requires the same backwashing as sand filtration. In addition, many local governments no longer allow the discharge of water containing DE into their municipal sewage systems. Also, even after backwashing, DE grids often need to be unbolted from their filter housing and scrubbed to ensure proper cleaning. This high level of maintenance and the waste associated with backwashing, has prompted many in the industry to turn to the third alternative: cartridge filtration. Over the past decade, cartridge filtration has become increasingly popular in new pool installations and as replacements for aging sand and DE filters.

In comparison, cartridge filtration is easy to maintain and cost effective. They do not require backwashing; the homeowner, rather than a service technician, can typically handle maintenance. They are also easily replaced, with the old filters being thrown in the trash and swapped out with new ones in the housing.

Effective and efficient

A new filter cartridge will capture 100 per cent of all particles larger than 30 microns (one micron equals 1/25,000th of an inch); particles smaller than 40 to 50 microns are not visible to the naked eye. Like sand and DE filtration, as a filter cartridge is in use, the filtration fabric will actually start to ‘load’ with particles, making the filter more efficient. After loading, the cartridge will naturally capture a higher percentage of smaller particles even as small as five microns. As any filter captures (loads) particles, the path for other material to move through the filter gets smaller and more complex, making any filter more efficient in trapping more matter of a smaller size.

[2]

[2]Larger particles will be trapped on the surface of the filtration fabric; these can be washed off simply with a quick run of the hose. Smaller particles will actually penetrate the media and cannot be washed off. Over time, filter cartridge efficiency will be reduced, as it becomes loaded with these small, invisible particles. For pool applications, if the bathing season is less than six months, a filter cartridge will generally last for two years; if the pool season is longer than six months, the cartridge will last approximately one year.

In spa applications, hot water will remove oils and other contaminants from bathers more rapidly than cooler pool water. Therefore, filter cartridges are more apt to become clogged and need to be replaced. Where homeowners use their spas regularly, replacing filter cartridges every three to six months is recommended. Using a filter cartridge beyond its recommended life can increase the wear and tear on other more expensive components (e.g. pumps) because of the extra force needed to move water through the filtration system.

Some use inferior filtration fabric, which can clog quickly and fail to achieve proper water cleanliness.

Cartridge filtration fundamentals

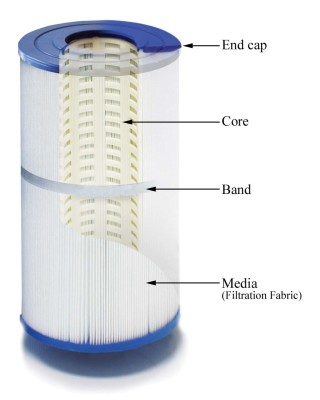

Not all filter cartridges are the same. There are four main elements in an effective cartridge filtration system: the core, media (filtration fabric), bands and end caps.

Core

[3]

[3]A properly designed core enhances flow rates, reduces head loss (lost pressure or velocity of a flowing fluid between two points created by friction) and maximizes filtration. This improved flow reduces wear and tear on the pump, uses less energy and extends cartridge life. This becomes even more important given the recent trend of switching to energy-efficient variable-speed pumps. When a pump is on low speed and saving energy, a core that maximizes flow will make it easier for water to move through the filter, maximizing the filtration area and creating uniform flow distribution through the entire cartridge.

In contrast, a poorly designed core will create water channelling, which reduces the usable area of the filter cartridge (i.e. a 9.2-m2 [100-sf] filter will work only as effectively a 4.6-m2 [50-sf] filter). A high-quality filter cartridge with a good core is even more important for larger inground pool applications, where as many as four filter cartridges are installed. In these situations, anywhere from 14 to 18.5 m2 (150 to 200 sf) of filtration fabric is used. In such a complex installation, improper flow distribution greatly decreases usable filtration area, making for an inefficient filtration system.

The consequences of poor flow are significant. Increased pressure will have a negative impact on every component in the filtration system, resulting in early failure. Filtration fabric is the most expensive component of a filter cartridge; if a poorly designed core inhibits the full use of the media, money is wasted.

Media/filtration fabric

Virtually all major filter cartridge manufacturers use the same media—spun-bonded polyester filtration fabric. This media is bonded together by entangling the fibre (filaments) without using adhesives. This material ‘depth loads,’ meaning some particles will actually get imbedded into the fabric and can not be cleaned out, as previously explained. Eventually, the media will become inefficient. In a spa setting, this is indicated when a filter quickly inhibits water flow right after cleaning. In pool applications, a clogged filter can be identified by rapidly increasing tank pressure, indicated on the pressure gauge. If this happens, it is time to replace the filter cartridge.

[4]

[4] [5]

[5]To function most effectively, filtration fabric must be long-lasting and free of fillers, additives or binders, which could serve as potential contaminants that might leach into the water during filtration. Further, the use of point-bonded material, which is less expensive, will reduce water flow, clog more easily and reduce filter life. This media uses additional adhesives to hold fibres together, which reduces flow (and media efficiency) and usually results in shorter filter cartridge life.

Higher-quality filtration fabrics, while more expensive, are also more resistant to rot and mildew, and will retain their physical characteristics when exposed to most solvents, oils, salt solutions, acids and alkalis. This uniform flow distribution results in even dirt loading, providing cleaner water and longer life. Superior filtration fabric is also easily cleaned and can be re-used several times. Lastly, higher-quality filtration fabrics are more uniform in their construction, which facilitates even water flow and provides more surface area to enhance the filtering process. When the fabric construction is uneven, water will move to the point of least resistance and larger particles will not be captured.

Bands

While they are often overlooked, bands are not used for esthetics—they serve a very valuable purpose. Bands should be tightly secured to each pleat for stability and strength. A properly secured band will help enhance flow, assure more consistent use of all the filtration fabric and increase a filter’s resistance to severe operating conditions. Too often, poorly constructed filters have no bands at all, or ones that fall off easily. Without proper bands, the pleats will actually fold over and the usable area of the filter will be reduced.

End caps

Strong end caps, which are specially formulated to withstand chlorine degradation, provide structural support and increase cartridge durability. If an end cap degrades over time, it can break into pieces and damage a pool’s pump. Today, anti-microbial end caps, which inhibit the growth of bacteria, are becoming more common.

The future

As the pool and spa industry continues to grow, many companies are working to revolutionize pool and spa filtration. These companies understand that people love their pools and spas, even through tough economic times. Regardless of the strength of the world’s economy, existing pools and spas need to be maintained. This gives rise to an increasingly competitive filtration market.

Cartridge filtration is evolving. New media are being developed and tested to increase water cleanliness without sacrificing ease of maintenance. Innovative designs are being developed, in which several different types of media are being used at the same time (e.g. one filter traps larger particles leaving smaller particles to another more expensive filter using a more advanced media).

Unfortunately, despite these technological advances, any filtration system will fail without proper maintenance or unbalanced water. In the end, pool and spa professionals must educate homeowners about the health and cost benefits associated with small incremental investments needed to properly maintain their pool or spa.

John Antretter is the chief operating officer (COO) of Pleatco LLC, a manufacturer of filter cartridges and grids for diatomaceious earth (DE) filters in Glen Cove, N.Y. He has lead the development of innovative products for over 20 years. His most notable success came as the chief executive officer (CEO) of Plasmaco, a leader in Plasma TV technology, which he sold to Panasonic. Antretter has been an adjunct professor of finance at Fordham University’s business school since 1991 and is a retired army captain. He can be reached at jantretter@pleatco.com[6].

John Antretter is the chief operating officer (COO) of Pleatco LLC, a manufacturer of filter cartridges and grids for diatomaceious earth (DE) filters in Glen Cove, N.Y. He has lead the development of innovative products for over 20 years. His most notable success came as the chief executive officer (CEO) of Plasmaco, a leader in Plasma TV technology, which he sold to Panasonic. Antretter has been an adjunct professor of finance at Fordham University’s business school since 1991 and is a retired army captain. He can be reached at jantretter@pleatco.com[6].

- [Image]: http://poolspamarketing.com/wp-content/uploads/2010/10/bigstock_filter__776283_edited-1.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/bigstock_Girl_Swimming_3131155.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/high-efficiency-cores-010-copy.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/Filter_Cartridge_Anatomy-copy.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/PleatcoDualCoreDualMediacross-section.jpg

- jantretter@pleatco.com: mailto:jantretter@pleatco.com

Source URL: https://www.poolspamarketing.com/trade/cartridge-filtration/