A simple switch

Although switching to a completely different method of treating pool water may seem like a challenge, the process of converting from traditional chlorination to salt chlorine generation is actually quite simple. In fact, the switch does not require any other equipment changes in the pump room, nor does the pool need to be drained. With today’s advancements in chlorine generator technology, the introduction of this equipment into an existing commercial pool pump room has become quite simple.

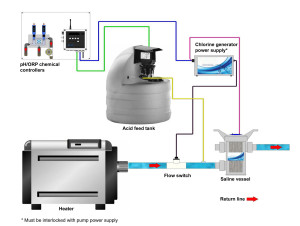

Newer commercial salt chlorine generators make use of small 120-volt power supplies in conjunction with a compact, single-cell electrode stack that produces more than 2.26 kg (5 lbs) of chlorine per day, which is enough to handle the application’s peak demands.

Historically, these systems were manufactured to operate as their own entity and were quite difficult to integrate with automated pH and oxidation-reduction potential (ORP) chemical controllers. With the growing awareness of chemical automation due to the rising occurrences of waterborne illnesses and increased legislation, manufacturers have initiated ways to make the adaptation of water chemistry controllers seamless with commercial salt chlorine generators.

For example, most commercial units now have ‘plug-and-play’ options, where the chlorine generator has a primary power supply cable that plugs into a standard ground fault circuit interrupter (GFCI), and a separate male cable that plugs into an automated pH and ORP chemical controller. This setup allows chlorine levels to be maintained more accurately. Once the chlorine generator is plugged into the controller, chlorine is only delivered to the pool based on actual demand, not on percentages or timers. This not only keeps chlorine levels more accurate, but also simultaneously adjusts the pool’s pH level to ensure the water remains balanced for more active chlorine and safer bathing conditions.

Additionally, automated controller manufacturers have taken their technology one step further by providing the ability to control a salt chlorine generator as the primary source of sanitization, while offering the capability of controlling a secondary backup chlorination system with a separate ORP set point for added safety in commercial pools. This increases water chemistry safety as the chlorine generator is allowed to handle sanitation demands unassisted until the controller is made aware of an extraordinary situation where it will power an additional chlorine feed system to assist the chlorine generator to ensure safe water conditions.

Salt chlorine generating systems offers a great deal of benefits to the entire spectrum of stakeholders within the commercial pool market. As mentioned earlier, comfort, convenience, and cost-savings are the primary factors for this change. Each of these alone drives demand for the switch from traditional liquid/tablet chlorine as the primary sanitizing method for commercial pools.

The introduction of new technologies, ease of installation and operation, as well as increased product longevity, will now serve to play an important role in this paradigm shift. It appears chlorine generators are poised to become a common feature in the commercial swimming pool industry.

M. Troy McGinty is the global product manager for commercial products for Hayward Commercial Pools a division of Hayward Industries, a pool equipment manufacturer. He first became involved in the pool and spa industry in 2003 and has developed and commercialized a number of swimming pool and spa products. He is a Certified Pool Operator/Instructor (CPOI), Aquatic Facility Operator (AFO) and has led numerous seminars and training sessions across North America on the topic of pH and ORP automation, communication, and business development. He can be reached via e-mail at mtmcginty@haywardnet.com.

M. Troy McGinty is the global product manager for commercial products for Hayward Commercial Pools a division of Hayward Industries, a pool equipment manufacturer. He first became involved in the pool and spa industry in 2003 and has developed and commercialized a number of swimming pool and spa products. He is a Certified Pool Operator/Instructor (CPOI), Aquatic Facility Operator (AFO) and has led numerous seminars and training sessions across North America on the topic of pH and ORP automation, communication, and business development. He can be reached via e-mail at mtmcginty@haywardnet.com.

Ray Denkewicz is the global product manager for sanitization and chemical automation for Hayward Industries, a pool equipment manufacturer. He first became involved in the pool and spa industry in 1994 and has developed and commercialized a number of swimming pool and spa products. Denkewicz has also been an active contributor to technical meetings, groups and committees with various pool and spa associations and has co-authored three symposia on swimming pool and spa water chemistry. He can be reached via e-mail at rdenkewicz@haywardnet.com.

Ray Denkewicz is the global product manager for sanitization and chemical automation for Hayward Industries, a pool equipment manufacturer. He first became involved in the pool and spa industry in 1994 and has developed and commercialized a number of swimming pool and spa products. Denkewicz has also been an active contributor to technical meetings, groups and committees with various pool and spa associations and has co-authored three symposia on swimming pool and spa water chemistry. He can be reached via e-mail at rdenkewicz@haywardnet.com.