Constructing safe water play parks that offer universal accessibility

All there is to know about recirculating systems

A skid-mounted recirculation system is manufactured off-site and each system has the same design specifications. These units are often referred to as off the shelf equipment. One drawback with this equipment is many skid-mounted recirculating systems are undersized.

Therefore, the installation of custom filtration systems that are designed to meet the needs and demands (e.g. high bather loads) of the specific splash pad project are recommended.

The recirculation system should be designed to handle heavier bather use during peak periods. Similar to a heavily used pool, which would require a four-hour turnover, a splash pad should have no less than a 20-minute turnover rate. This means the water goes through the filter and ultraviolet (UV) system three times per hour, 72 times per day. It is critical the water is bacteria-free and safe for bathers, as anything less could potentially compromise patrons’ health.

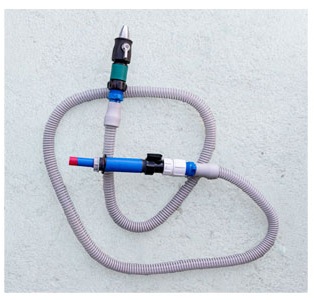

Custom recirculation systems require a UV sanitizer (as mentioned earlier) in addition to a chemical controller to ensure proper water chemistry and pH levels.

Handling rain water

One important consideration for splash pads using a recirculating filtration system is what to do with rain water that accumulates on the concrete deck and flows into the splash pad’s balance tank. To keep water in the balance tank at the prescribed level, an electric valve connected to the drain line will open and divert water to the sewer (waste) when the splash pad is not being operated.

When this occurs, the filtration and sanitizer system will still operate to treat the water in the surge tank. When the splash pad is operating, the electric valve diverts the water on the splash pad to the balance tank.

A range of water toys

Most suppliers manufacture water toys using stainless steel, reinforced fibreglass, or a combination of the two materials. Both are marketed as being highly durable. The biggest difference, however, is the versatility each material has with respect to creating various designs and shapes.

For instance, fibreglass can be moulded into any shape or form (e.g. creative creatures or animals, depending on the theme of the splash pad). In this author’s experience, the longevity of splash pad equipment manufactured using fibreglass far surpasses stainless steel, as over time the latter will rust and corrode.

There are also many different types of water toys, ranging from surface spray to multi-level structures. Some splash pads are designed using only surface sprays, while others use a combination of surface sprays and above-ground features. The latter might be interactive or have dumping buckets and other elements of surprise. Multi-level structures are designed with a lot of interactive elements and sometimes incorporate slides.

Splash pads have evolved over the years. The first designs were very simple, comprising a concrete pad with a simple stainless steel pole with water gushing out of the top. Today, however, these water play features have progressed into concrete pads with resilient surfaces and a multitude of spray features and toys, often interactive and themed.