Electronic hot tub components

by Sally Bouorm | June 1, 2010 12:06 pm

![Photo courtesy Gecko Alliance Jean-François Cloutier [#Beginning of Shooting Data Section] Nikon D2Xs 2007/07/05 10:31:12.9 Jpeg Fine (8 bits) Taille d'image : Moyenne (3216 x 2136) Couleur Objectif : 28-105 mm F/3.5-4.5 D Focale : 40 mm Mode d'exposition : Manuel Mesure : Mesure matricielle 1/200 s - F/8 Correction expo. : 0 IL Sensibilité : ISO 100 Optimisation image : Balance des blancs : Flash +2 Mode mise au point : AF-S Réduction de vibration : OFF Réduction du bruit : Désactivée Réduc. bruit ISO : Désactivée Mode couleur : II (Adobe RVB) Correction des tons : Normale Réglage des teintes : 0° Saturation : Normale Netteté : Moyen élevée Mode de flash : Optionnel, M Mode synchro flash : Premier rideau Authentifier : Désactivé Légende image : [#End of Shooting Data Section]](http://poolspamarketing.com/wp-content/uploads/2010/06/in.axess-03.jpg) [1]

[1]

Hot tub and swimming pool electronics are completely different. As such, service technicians should have specific training in troubleshooting and repairing hot tub components, as today these products feature a greater number of jets and more powerful jet pumps, not to mention a variety of optional equipment such as stereos, TVs, DVD/CD players and lighting features.

The process of troubleshooting hot tub electronics is not really that complicated; in fact, it sounds more complex than it actually is. Any electrical work and repair, however, can be dangerous, especially around water, so extreme care is strongly advised.

The following tips and guidelines will help hot tub service technicians troubleshoot and resolve some of the major electrical component faults that are commonly encountered in the field.

Nothing works!

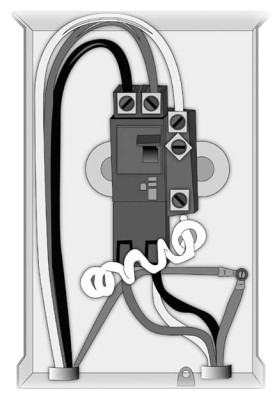

As per the Canadian Electrical Code, every hot tub installed in Canada must be hooked up through a ground fault circuit interrupter (GFCI). These devices quickly disconnect a circuit when current leakage is detected. When a current leak of more than five milliampere (5 mA) is detected, the breaker ‘trips’ (disconnects) to prevent electrical shock.

[2]

[2]Although these devices have been known to save lives, they will fail to serve their intended purpose if not installed properly. Additionally, when wires get crossed a GFCI can become a source of frustration for hot tub installers and technicians alike, as tripping problems will occur, which can be tricky to diagnose.

The following are some suggestions for service technicians troubleshooting a GFCI that detects a leak:

- A miss-wired GFCI can cause the device to instantly trip. As the connection of the neutral conductor in a GFCI device is different than a regular breaker, this can be a common problem. The neutral on the load side of a GFCI is not connected to the neutral bar, as it is on a regular breaker.

- If the GFCI has been connected properly but continues to trip, the next step is to disconnect all of the components connected to the spa pack, then reconnect them one at a time. When the GFCI trips, it will indicate which component is causing the current leak. In most cases, the culprit will be an ozonator or heater.

This test cannot be performed by disconnecting only one lead from the heater—all leads must be disconnected. Furthermore, if an ozonator is determined to be the cause, it is usually because water is entering the unit. In this case, be sure to replace the unit’s check valve.

Flow error

Most hot tubs today are equipped with heaters that use pressure-sensing devices to ensure the unit has sufficient flow to cool itself for proper operation.

![Photo courtesy Gecko Alliance Jean-FrancÃßois Cloutier [#Beginning of Shooting Data Section] Nikon D2Xs 2007/06/20 14:41:31.6 RAW (1](http://poolspamarketing.com/wp-content/uploads/2010/06/K200_FLO-copy-400x151.jpg) [3]

[3]

Before troubleshooting a flow error, first locate the pump that pushes water through the heater to verify it is working properly. The spa pack should trigger the pump to turn on when heat is demanded. If it fails to operate, troubleshoot the problem as a pump-related issue, not a flow error.

If the pump engages but no flow is detected, verify the pressure sensor is working properly. If bypassing the pressure sensor is possible, do so for test purposes only, as leaving this device on bypass is a safety hazard. If the sensor cannot be bypassed, use one of these methods to check flow related problems:

- Make sure the pump is not air locked;

- Remove the filter to check for any blockage; and/or

- Verify all air diverters are open.

If the system’s flow is working properly but a problem still remains, the next step is to replace the flow-sensing device.

Inaccurate temperature readings

When troubleshooting a temperature reading error, the first step is to confirm the problem. To do this, use a calibrated digital thermometer to compare the hot tub’s keypad reading with the actual water temperature.

If the temperature reading is within two degrees, it is possible the results are within the accuracy of the test. If the control and thermometer have a +/- one-degree accuracy, the results are within acceptable levels.

If the temperature is not accurate, the hot tub’s temperature sensor must be located. It can usually be found in the body of the water or inside the heater barrel. If it is located inside the heater barrel, it will need to be replaced (with the included probe) to correct the problem.

If the sensor is located outside of the heater barrel, place a spare sensor in the water. If the proper temperature is displayed, the problem can be narrowed down to the sensor itself or simply the way it was installed. If the new probe recreates the same problem, installation is the cause.

If placing a new probe in the water does not result in any change, replace the controller, as something is wrong on the main board.

Hi-limit error

The electronic control is equipped with a second temperature probe located on the heater barrel called the hi-limit probe. This device can also be part of the sensing probe located inside the heater barrel. The hi-limit control works by stopping the heater when it senses the water has reached the highest acceptable temperature limit.

If the temperature increase was caused by a runaway heater (i.e. a heater that continues to heat the water even though it has already reached its appropriate temperature), this device will prevent the hot tub from reaching temperatures over 48.3 C (119 F).

If the cause of overheating is not a runaway heater, but a runaway pump, only a controller equipped with kinetic heating protection will prevent the hot tub water from overheating. Kinetic heating protection manages water temperature increase generated by pump heat dissipation and protects the hot tub’s equipment by automatically shutting down all accessories when the water temperature reaches high limits.

When troubleshooting a hi-limit problem the first thing to look for is the temperature of the water when the hi-limit warning appears. Is it close to 48.3 C?

If it is, only three things can increase the temperature of the hot tub water: outside temperature, a heater or a pump. If the outside temperature is higher than the hot tub’s water temperature, the water temperature will increase, as heat created by the pump or heater will not be lost to the environment.

If the exterior temperature is not an issue, then the heater or the pump is remaining on (runaway). This is easy to troubleshoot. First, the temperature on the heater barrel must be below 48.3 C, so gently feel the area of the probe to see if it is hot. If it is, cool down the area and reset the breaker to reset the error. When the error is clear, test the heater output to see if the connection still reads 240V when the heater icon is not displayed. If so, when the pump stops, the flow switch will not stop the heater and the technician will see and hear the heater overheat.

If the heater is not to blame, the pump is the culprit. When a pump runs, the heat created by the motor overheats the ambient air under the hot tub skirt, which is then transferred into the water. This is called kinetic heat.

In this case, it is important to first verify if the pump is running when is should be off. If it is running, the main board is defective, as it is allowing the pump to engage when it should be off.

If the temperature is nowhere near 48.3 C on the heater barrel, then either the controller or its probe is at fault. If either is defective, the error cannot be reset by simply turning the breaker on and off.

If the error can be reset but reoccurs after some time, there may be a blockage in the circulation system that is causing a local overheat. If this is the case, the pump and all plumbing—from the heater to the jets—should be checked for any restrictions.

Sophie Tremblay is the technical service department manager for Gecko Depot. She is an electrical engineer by trade and has been working with Gecko Alliance for 13 years. During this time she has conducted several educational seminars on troubleshooting electronic controls.

Sophie Tremblay is the technical service department manager for Gecko Depot. She is an electrical engineer by trade and has been working with Gecko Alliance for 13 years. During this time she has conducted several educational seminars on troubleshooting electronic controls.

- [Image]: http://poolspamarketing.com/wp-content/uploads/2010/06/in.axess-03.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/GFCI.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/07/K200_FLO-copy.jpg

Source URL: https://www.poolspamarketing.com/trade/electronic-hot-tub-components/