Eliminating overly caustic environments in indoor aquatic facilities

UV lamps

There are two types of UV lamps, low pressure (LP) and medium pressure (MP); they differ in several important ways. The term ‘pressure’ refers to the internal gas pressure within the construction of the lamp itself. An LP lamp only emits UV energy at one wavelength (254 nm), while MP lamps are polychromatic and emit UV energy at every wavelength (between 200 to 300 nm).

Benefits of using an MP lamp

Due to the higher level of energy a single MP lamp can produce, it can replace 10 to 20 LP lamps, which makes them a less costly option for many commercial applications. Other advantages include:

- Multiple wavelengths of an MP lamp attack more of the pathogen’s cell structure—unlike an LP lamp. Some pathogens can actually use light energy to repair damage caused by UVC energy through a process known as photoreactivation (PR). Using an MP lamp can prevent reactivation from occurring, which is significant in swimming pools where the pool water is exposed to sunlight energy after being exposed to germicidal UV energy;

- The energy output of LP lamps decreases in hot or cold water, while energy output of an MP lamp is not affected by temperature extremes;

- Science has shown MP wavelengths below 240 nm are more readily absorbed by chloramines in comparison to the 254-nm output of an LP lamp; and

- LP lamps provide germicidal energy using less electricity; however, commercial systems often require a range of four to 18 lamps, where in the case of an MP lamp, only one or two would be required. The larger the volume, the greater the savings using MP lamps when calculating equipment, installation, spare parts, service costs and electricity.

Components

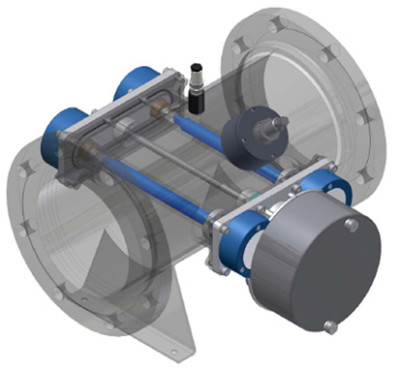

A UV system comprises a 316-L stainless-steel chamber, which contains one or more UV lamps and a power/control cabinet. The lamp does not actually come in contact with pool water as a hollow quartz sleeve or tube isolates it. Over a period of time, the tube will develop deposits from oils and organic materials in the water, which blocks the emission of UV light. To combat this, many manufacturers have incorporated an automatic internal wiping mechanism to clean the sleeve and remove any buildup of deposits. These systems also use a UV monitor, which provides a real-time reading of the lamp’s output through the quartz sleeve and water. If any one of these factors affects the energy delivered, an alarm will sound in the power/control cabinet. Depending on the system, some cabinets have an LED display to indicate the energy being measured by the UV monitor.

For most industrial UV applications, UV systems are plumbed after the filter and before chemical injection for three reasons:

- In almost every case, UV systems for swimming pools are installed after the filtration equipment to remove chloramines and disinfect the water. Filters are ideal areas for microbiological growth due to organic materials being trapped in its large surface areas. This makes high-level UV disinfection, immediately after filtration, a good idea.

- Filters improve the transmission of the water by aiding the ability of UV energy to penetrate and perform as required.

- The UV chamber is a glorified piece of pipe with lamps mounted inside. The pool filter acts as a physical barrier and prevents rocks or other large objects from passing through the UV system and potentially breaking the lamp. It is worth noting, the litigious implications of broken quartz in a swimming pool has resulted in many manufacturers supplying a mesh strainer basket immediately after the UV to protect against this risk.