Eliminating overly caustic environments in indoor aquatic facilities

by Sally Bouorm | March 1, 2010 10:34 am

[1]

[1]By Tom Schaefer

An increasing number of indoor aquatic facilities are using ultraviolet (UV) technology to improve indoor air quality, as its energy can naturally breakdown some byproducts of chlorine use including, odour, bather irritation and enhanced corrosion associated with these environments.

While chlorine use is hailed as one of the greatest achievements of modern man, studies have documented its disinfection byproducts (DBPs) are harmful in high concentrations. For example, athletic asthma on competitive swim teams and respiratory ailments by aquatic staff can be traced to poor air quality. The primary benefit of using a UV system in an indoor aquatic facility is to improve air and water quality by lowering the concentrations of harmful DBPs.

[2]

[2]Another benefit of using UV, whether for an indoor or outdoor pool, is that it also disinfects to a very high level. UV light can be subdivided in a number of ways, for example, UVC (the short wave or germicidal band) forms a near instant bond in the DNA (deoxyribonucleic acid) and RNA (ribonucleic acid) of pathogens; preventing them from replicating and effectively killing a wide range of pathogens. Chlorine is still required, however, because UV does not leave a residual effect in the water and only treats the water passing through the filter return line.

Another benefit of UV technology is its effectiveness against some pathogens that are resistant to chlorine. There is also a movement among health departments to address these ‘chlorine resistant’ pathogens, not only in municipal drinking water, but public pools as well. Throughout North America there have been numerous aquatic outbreaks of Cryptosporidium (Crypto) over the last few years. In 2007, it is estimated 20,000 people were afflicted during an outbreak in Utah.

Cryptosporidium is a naturally occurring protozoan parasite, which can cause an intense gastro-intestinal illness that is potentially life threatening to infants, the elderly and immune-compromised individuals. Crypto has a hard outer shell, which protects it from the disinfecting capabilities of chlorine.

The U.S. Centers for Disease Control (CDC) notes chlorine achieves a 99.9 per cent disinfection rate of Crypto, with one parts per million (ppm) of free chlorine in 10.6 days. UV systems for swimming pools are sized to provide a minimum of five times the level of energy required to achieve a 99.9 per cent disinfection level, which is continuously applied to the filtered water.

An accidental discharge of Crytpo can easily result in millions of oocytes being shed into the pool. Ingesting these in small numbers can result in patrons being afflicted with Cryptosporidiosis. Often times, a discharge in a swimming pool is not known until people start becoming ill. With symptoms appearing, on average, seven days after ingestion, hundreds or thousands of bathers can be exposed before the presence of Crypto is identified.

UV cannot eliminate the risk, but it can dramatically reduce the number of viable oocytes in a short period of time as it continuously treats 100 per cent of the filtered water, which significantly reduces the threat within a few turnovers of the pool’s water.

UV science

Similar to a household lamp for interior lighting, UV systems use more powerful mercury lamps made of quartz, which unlike glass, allows UVC energy to pass through into the water.

Many are familiar with the terms UVA (long wave or black light) and UVB (medium wave) energy, which causes skin to tan or burn, depending on the length of exposure in the sun. UVC energy, however, is more powerful and beneficial for breaking down chloramines, as well as disinfecting a wide range of bacteria, viruses, moulds and protozoas. It is worth noting UVC energy from the sun is easily absorbed by earth’s atmosphere, which eliminates human exposure.

The range of UVC energy is about 100 wavelengths in width along the light energy spectrum, which is located between 200 to 300 nanometers (nm). A bell curve of germicidal energy exists within this range and is most powerful for disinfecting around 260 to 265 nm. Chloramine control is most effective below 240 nm, as photon energy increases as the size of the wavelength is reduced. Significantly more energy is absorbed to disrupt the chemical structure of chloramines near 200 nm and decreases significantly above 240 nm.

UV lamps

There are two types of UV lamps, low pressure (LP) and medium pressure (MP); they differ in several important ways. The term ‘pressure’ refers to the internal gas pressure within the construction of the lamp itself. An LP lamp only emits UV energy at one wavelength (254 nm), while MP lamps are polychromatic and emit UV energy at every wavelength (between 200 to 300 nm).

Benefits of using an MP lamp

Due to the higher level of energy a single MP lamp can produce, it can replace 10 to 20 LP lamps, which makes them a less costly option for many commercial applications. Other advantages include:

- Multiple wavelengths of an MP lamp attack more of the pathogen’s cell structure—unlike an LP lamp. Some pathogens can actually use light energy to repair damage caused by UVC energy through a process known as photoreactivation (PR). Using an MP lamp can prevent reactivation from occurring, which is significant in swimming pools where the pool water is exposed to sunlight energy after being exposed to germicidal UV energy;

- The energy output of LP lamps decreases in hot or cold water, while energy output of an MP lamp is not affected by temperature extremes;

- Science has shown MP wavelengths below 240 nm are more readily absorbed by chloramines in comparison to the 254-nm output of an LP lamp; and

- LP lamps provide germicidal energy using less electricity; however, commercial systems often require a range of four to 18 lamps, where in the case of an MP lamp, only one or two would be required. The larger the volume, the greater the savings using MP lamps when calculating equipment, installation, spare parts, service costs and electricity.

Components

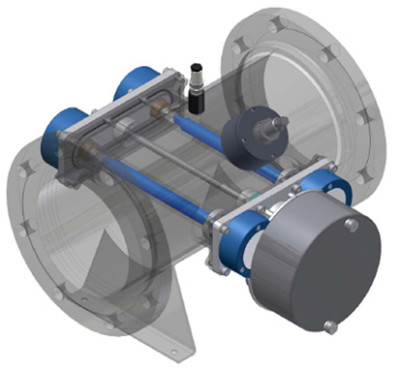

[3]

[3]A UV system comprises a 316-L stainless-steel chamber, which contains one or more UV lamps and a power/control cabinet. The lamp does not actually come in contact with pool water as a hollow quartz sleeve or tube isolates it. Over a period of time, the tube will develop deposits from oils and organic materials in the water, which blocks the emission of UV light. To combat this, many manufacturers have incorporated an automatic internal wiping mechanism to clean the sleeve and remove any buildup of deposits. These systems also use a UV monitor, which provides a real-time reading of the lamp’s output through the quartz sleeve and water. If any one of these factors affects the energy delivered, an alarm will sound in the power/control cabinet. Depending on the system, some cabinets have an LED display to indicate the energy being measured by the UV monitor.

For most industrial UV applications, UV systems are plumbed after the filter and before chemical injection for three reasons:

- In almost every case, UV systems for swimming pools are installed after the filtration equipment to remove chloramines and disinfect the water. Filters are ideal areas for microbiological growth due to organic materials being trapped in its large surface areas. This makes high-level UV disinfection, immediately after filtration, a good idea.

- Filters improve the transmission of the water by aiding the ability of UV energy to penetrate and perform as required.

- The UV chamber is a glorified piece of pipe with lamps mounted inside. The pool filter acts as a physical barrier and prevents rocks or other large objects from passing through the UV system and potentially breaking the lamp. It is worth noting, the litigious implications of broken quartz in a swimming pool has resulted in many manufacturers supplying a mesh strainer basket immediately after the UV to protect against this risk.

Sizing and installation

[4]

[4]UV disinfection is easier to accomplish relative to chloramine control. Before sizing a system, first determine whether the pool is indoors or outdoors. Chloramine control is not typically an issue with outdoor pools, whereby vapours simply blow away in the breeze.

Before implementing UV technology, however, several things must be kept in mind. Water quality and temperature, bather load, turnover rate, plumbing size, regulatory considerations, filtration design, environmental concerns and the availability of local, factory-trained service personnel are a few of the many considerations used when selecting a system.

It is also wise to work with an experienced company and to select an NSF/ANSI Standard 50 listed product. This standard, Equipment for Pools, Spas, Hot Tubs, and Other Recreational Water Facilities (2009), contains a wide variety of requirements, which address materials, products and equipment used at recreational water facilities. It also includes items used in water circulation, filtration, treatment and monitoring of residential and public swimming pools, spas, hot tubs and water parks.

Health departments are also starting to incorporate UV technology into aquatic codes and are requiring ‘validated’ units, whereby testing by an accredited independent third party is involved.

Testing protocol is often based on municipal drinking water standards and differs from country to country. Health codes requiring validated units should base the standard on performance level. For example, validation should be based on reduction of a target pathogen rather than on energy level, which can be interpreted differently depending on the respective country’s testing protocol.

For existing facilities, retrofit installations are typically easy and can be completed in a day or two. However, the pool is only closed for a few hours, while the bypass is plumbed into the filtration line. A factory-trained technician should commission the newly installed system; making sure all the wiring from the cabinet to the chamber is properly connected and the programming is specific to the actual pool.

Service

All process equipment needs to be maintained and UV is no exception. Typically, each UV chamber will require a regularly scheduled maintenance program consisting of approximately four hours every six months. There are a limited number of expendable components, which will require manual cleaning and/or replacement.

Often, UV is installed in a bypass to allow the system to be serviced while the pool remains open. Unless mandated by health code, a UV system that is out of service for one or two days should not be a concern. Although chloramine levels rise steadily, however, not rapid enough to necessitate closing the pool.

It is highly advised to have a factory-trained technician perform the first few service calls to allow onsite technical service staff to train alongside. The UV lamp and quartz sleeve are relatively fragile and expensive; if a factory technician should break or damage any components during service, the customer will not have to pay for additional parts.

Another benefit to having factory-certified service is to assure proper performance, thus establishing a baseline the customer can expect year after year. Unlike chemical feed systems, which oxidize, UV is nothing more than powerful lamp(s) in a 316-L stainless steel body, and if maintained properly, it will last many years. Some manufacturers also offer extended warranties if service contracts with factory-trained technicians are in place.

Tom Schaefer is a swimming and leisure specialist with Engineered Treatment Systems, LLC (ETS) in Beaver Dam, Wis. He has been involved with manufacturer sales of medium pressure (MP) UV systems for commercial aquatic facilities for over 10 years. He can be reached via e-mail at tschaefer@ets-uv.com[5].

Tom Schaefer is a swimming and leisure specialist with Engineered Treatment Systems, LLC (ETS) in Beaver Dam, Wis. He has been involved with manufacturer sales of medium pressure (MP) UV systems for commercial aquatic facilities for over 10 years. He can be reached via e-mail at tschaefer@ets-uv.com[5].

- [Image]: http://poolspamarketing.com/wp-content/uploads/2010/03/Pool_1072309_edited-1.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/08/Park_5970609.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/08/tech-ecp-drawing.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/08/TwinLakes_25.jpg

- tschaefer@ets-uv.com: mailto:tschaefer@ets-uv.com

Source URL: https://www.poolspamarketing.com/trade/eliminating-overly-caustic-environments-in-indoor-aquatic-facilities/