Emerging technologies assist vinyl liner and safety cover installers

By Brian Jewell, P.Eng

Pool measuring has been a large part of a service professional’s job for many years. The skill to measure accurately takes training, patience, and time as they are necessary for the successful installation of high-priced custom fabricated vinyl liners and safety covers. Correct measurements not only ensure products fit properly, but also help projects operate more efficiently. The end result leads to reduced installation labour, satisfied customers, quicker payment, and a reputation for quality work.

The consequences of poor measurements can be disastrous for an installer. Shoddy work can mean having to re-measure a pool for replacement orders, dissatisfied customers, difficulty in collecting payment, and increased labour costs. Even if the installation can be completed, the lifespan of a poor-fitting vinyl liner may be compromised due to wrinkles, premature fading, and tension, which further leads to tears or separation from the pool coping.

These problems can be costly, which has motivated the industry to look for ways to improve the ease and accuracy of pool measuring. The innovative results have allowed for more successful installations and increased revenue for installers. The developed measuring methods have also allowed for more complex designs. Rather than simple rectangle and round vessels, pool shapes have become extremely complex, including vinyl-covered swim outs, vinyl-over stairs, as well as safety covers covering complex water features, etc. All of these complicated features and designs are supported by better measuring techniques and technology.

Newer methods have also aimed to save the installer time, which is extremely important during the short pool season. Good ‘A-B’ measurements can take a two-person team roughly an hour to complete; however, using today’s newer technology, the time saved can be used to generate additional income instead.

Measuring pools using photographs

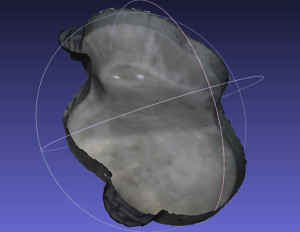

Technology using digital photographs to create 3D pool models is one of the most recent developments available to industry professionals. This technique involves taking approximately 20 eight-megapixel photos of the pool from various locations. After they are submitted to the manufacturer, they are processed to generate an accurate 3D pool model. These models are then used to manufacture custom items such as vinyl liners and safety covers. The accuracy and simplicity of the technology provides incredibly precise results with minimal effort. Further, the only hardware required is an eight-megapixel camera.

The picture measuring technology captures complex items such as freeform lines or concave and convex surfaces. Pools of complex geometry can be measured by a single worker in a few minutes with very little training or instruction.

However, before photos can be taken as part of this measuring technique, the pool must be near empty and relatively dry. Further, taking ‘good’ pictures are important to getting accurate results; therefore, photos must be clear and in focus without any moving objects in the pool. Water-filled areas of the pool will not generate a 3D model.

Some point-and-shoot cameras as well as most mobile phones have the capability to take photos at the quality required for the 3D modelling software.

Thousands of items within each high-resolution photo are recognized. By recognizing the points in the photos, and the relative distance between them, their 3D location can be determined using algebra. The photos are processed using software to identify all of the recognized locations. All of the processing and expertise is completed by the fabricator’s design staff and is not a concern for the installer. The installer simply provides the photos along with a few measurements, depending on the manufacturers request. These measurements are used to properly scale the 3D model.

| Advantages | Disadvantages |

| • Model entire pool, including floor shape. | • Pool must be empty. |

| • Accurate. | • No results until submitted and processed by the manufacturer. |

| • Fast. | |

| • Inexpensive equipment. |