Emerging technologies assist vinyl liner and safety cover installers

Laser measuring systems

Laser measuring systems entered the market in a more significant way approximately three years ago. Lasers offer incredible accuracy—within 1.6 mm (0.062 in.)—and can be used to calculate lengths, widths, and heights up to approximately 198 m (650 ft). They can also be used to measure complex pool shapes. Laser 3D imaging systems can measure an entire pool extremely fast; including time for set-up, depending on how many source locations are required, a pool can be completely measured between 25 minutes to three hours (approximate).

Different source locations are needed when using this measuring system as the laser is a ‘line of sight’ device; if there are surfaces that cannot be seen from the laser location, it must be moved as many times as required to capture all of the pool surfaces.

The distance calculation is completed through precision optics and laser physics, using the phase-shift method, in which the laser hits an object and compares its reflection with the beam sent out, or using the time-of-flight method, whereby calculating the time it takes for an optical pulse to reflect back. Together with the laser orientation at the time the measurement is taken, the 3D point is defined. Taking thousands of measurements generates the 3D pool model.

The results can be seen and reviewed by the operator at the job site before being submitted to the manufacturer. The file output is in a convenient .DXF format, which is a common computer-aided drawing (CAD) format readily read and processed by manufacturers.

The equipment for a 3D laser measuring system is approximately $14,000 (U.S.) and there are a few options available from different manufacturers.

| Advantages | Disadvantages |

| • Model entire pool, including floor shape. | • Expensive hardware. |

| • Extremely accurate. | • Pool must be empty. |

| • Fast. | |

| • Able to review results in field. |

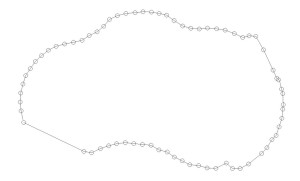

Triangulation

Triangulation (also known as A-B measuring) has been the industry standard for decades. It is an inexpensive method that requires little training. Using two stakes as a co-ordinate base, along with the distance between them, any point in the same 2D plane can be pinpointed by taking the distance from each of the stakes using multiple measuring tapes (one from each stake). Then, measurements from each stake to several points around the pool perimeter are taken, approximately one every 0.6 m (2 ft). This measuring method can take roughly an hour to complete on a relatively simple pool with two people on-site (one person to take the measurements and the other to record them).

Although the results from A-B measuring can be quite accurate, they are prone to errors as stake placement can lead to sensitivity of resulting plots, communicating and recording errors, measuring tapes getting caught on objects, points taken are too course to get good resolution, etc.

If the installer uses computer-based verification software, they should be able to identify most errors before leaving the field. A-B points are also limited to the pool perimeter and do not include definition of the pool floor.

| Advantages | Disadvantages |

| • Simple. | • Two dimensional. |

| • Inexpensive tools. | • Prone to errors. |

| • Results can be reviewed in the field (when used with software). | • Time consuming. |

| • Pool can be filled with water. | • Poor resolution/lack of detail. |