Making special considerations for a unique auto-cover install

by jason_cramp | November 30, 2017 12:00 pm

Installing automatic pool covers is the specialty of Pool Patrol in British Columbia. The company sells as many as 100 auto-covers every year in Vancouver, Victoria, Okanagan, and Kelowna; therefore, it was no surprise when the installer was contacted about a new project—a 5-m (16-ft) wide by 29-m (95-ft) long pool in need of a cover.

It was a good thing the builder and contractor knew the importance of consulting with a cover professional before starting construction, as special considerations were required due to the sheer size of the pool. Allan Horwood, Pool Patrol[1]’s owner, was consulted prior to the pool being constructed, and two years before the cover was installed.

The pool

The pool sits on a large property, roughly 0.8 ha (2 acres), located in the hills overlooking the greater Vancouver area. The pool’s interior is lined with small, coloured-mosaic tiles, while the concrete deck has a modern design that is accented with a dark-green tile arranged symmetrically to create a clean, stunning visual effect.

[2]

[2]Initially, Horwood had a few concerns about installing an automatic pool cover of this size; therefore, to guarantee it would meet the homeowner’s high-expectations for the project, he contacted his cover supplier to address a few things:

- Would the weight of the cover fabric be too heavy for the drum mechanism?

- Would the standard motor be strong enough to handle the operation of such a long cover, or would a higher torque motor be required?

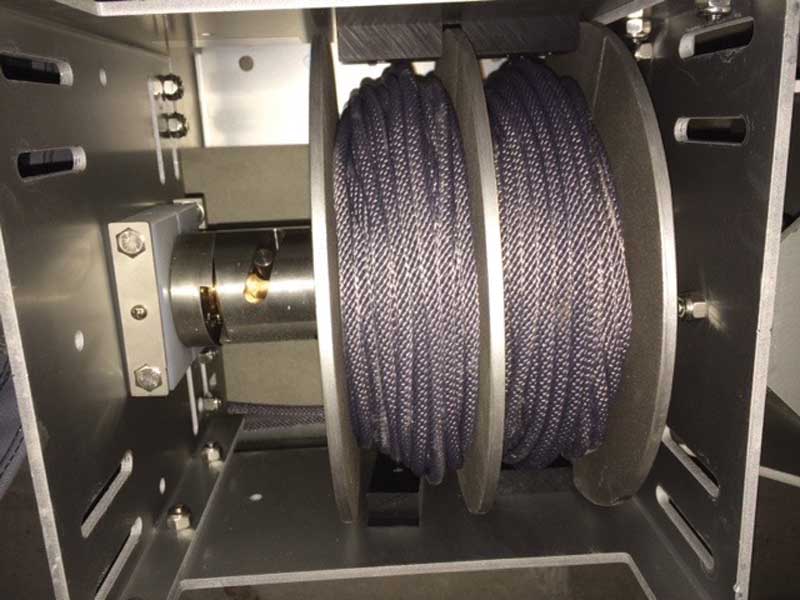

- Would there be enough room on the reel to accommodate 29-m (95-ft) of rope?

“Having worked on another project for this homeowner in the past, we didn’t want to commit to something that wouldn’t be perfect,” said Horwood. “At the same time, our company thrives on doing complicated, one-of-a-kind work, so we looked forward to the challenge.”

Housing the cover

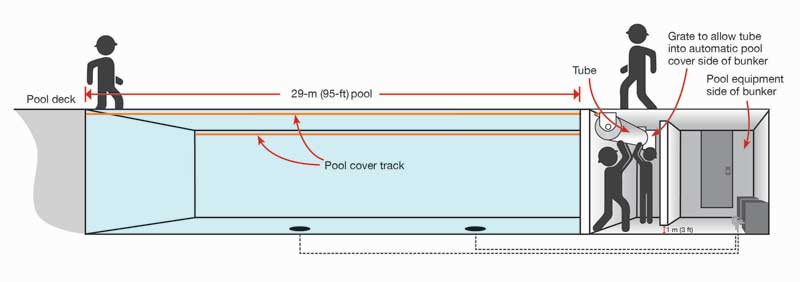

The homeowner was particular about every aspect of the pool design. One of the client’s main wishes was having a solid deck above the cover roll-up (i.e. no lid on the pool deck). Therefore, it was imperative for the cover to be housed entirely below the deck so it would not infringe on the architectural beauty of the pool surround.

As this type of installation could prove to be tricky, Horwood explained to the client that a large space would be necessary to house everything below deck—not just for the mechanism and cover, but also for the crew that would install and maintain it. Therefore, a 1.8-m (6-ft) tall bunker had to be created under the deck, which would allow technicians to stand up and easily move around.

[3]

[3] [4]

[4]In many cases, cover installers are called in too late to accommodate special requests such as this and, as a result, pool design and cover modifications need to be made after the fact.

For those unfamiliar with automatic covers, they are typically installed in a recessed concrete or pre-fabricated housing, which can be accessed from the deck via a lid made of aluminum or concrete. However, to accommodate this client’s request to install the cover and all of its components out of sight, the deck was suspended over a small bunker that was attached to the pump room, and hidden under the deck at the deep end of the pool. (Interestingly, the pool was originally designed to be 30.5-m (100-ft) long, but to accommodate the equipment room and cover bunker, it had to be shortened to prevent it from encroaching on the property line).

[5]

[5]In addition to its 1.8-m (6-ft) height, the automatic cover bunker is 0.9-m (3-ft) wide and is attached to the pump room via a 1.5-m2 (16-sf) hatch, which provides technicians an access point to the bunker. A concrete wall was built between the equipment room and the pool cover bunker to provide additional support and to reduce the amount of water that can enter the bunker when the cover is retracted. By designing these two rooms in this fashion, water is allowed to collect and drain inside the bunker without exposing the equipment. To install the drive system and roll-up tube into the cover bunker, a grate was added to the outside of the bunker, which, when removed, allowed the tube to be slid into the small opening.

Cover colour

For most automatic pool cover installations, homeowners are happy to choose from an array of standard colours that are available to match current outdoor décor trends. However, for this project, selecting the appropriate fabric colour was even more crucial, simply because a large amount of it would be visible. Further, the cover had to complement the colour of the concrete deck and accessories, while at the same time not be overpowering when it was closed.

That said, none of the standard samples met the homeowner’s vision for the pool area and, as a result, additional colours had to be sourced from a vinyl manufacturer in Europe. Despite receiving material samples to show the client, the homeowner felt a small swatch of fabric would not help them determine which colour would co-ordinate best with their backyard—especially considering the cover would encompass more than 141 m2 (1520 sf).

“The homeowner had paint created to match the fabric swatch they were considering and then painted a 2.4-m (8-ft) piece of plywood and laid it out on the deck to help them visualize if the colour would work,” said Horwood. “Once the homeowner was comfortable with the colour, the material was ordered.

“I was concerned about the availability of this fabric colour for when the cover needs to be replaced, as every cover needs to be exchanged at some point. When this time comes, it could definitely present challenges.”

That said, the homeowners were so pleased with their colour selection they ordered additional material, as well as enough to wrap their spa cover to co-ordinate it with the pool.

Installing the cover

[6]

[6]In most cases, a two-person crew can install an automatic pool cover in one or two trips. One of the most important things a cover installer should be able to do is accommodate the pool builder’s schedule. This is crucial because the automatic cover is typically the last component installed on the pool.

For this project, the automatic cover was delivered to the installer’s warehouse several weeks before the pool was ready for it to be put in.

“Due to the size of the pool (the cover fabric alone weighed well over 136 kg [300 lbs]) a four-person crew was needed to make sure it was installed in one day,” said Horwood, who worked closely with the pool builder, Howie Stevens of Stevens Pools in North Vancouver, B.C., to co-ordiante the timing of the install.

“The communication with Stevens Pools was superb, which helped make the installation go extremely smooth,” said Horwood.

The most complex part of the job was hanging the mechanism from the bunker’s ceiling. Fortunately, thanks to the pre-determined bunker size, it made it much easier for the crew to get into the area to drill, mount, and hang the mechanism and motor. Four people were required in tight quarters to move and hold the roller mechanism while it was being secured.

The cover was installed and tested several times to ensure it operated smoothly. To meet American Society of Testing and Materials (ASTM) F1346-91—Standard Performance Specification for Safety Covers, submersible cover pumps were provided to the homeowner. In most cases, only one pump is required; however, multiple pumps were needed on this project to meet the safety standard. These pumps are manually placed on the cover, when it is closed, to remove standing water into pre-determined deck drains surrounding the pool.

“In Vancouver, it is normal for it to rain continuously, sometimes for more than a month at a time, so the cover pumps are used frequently throughout the year,” said Horwood.

Opening and closing the cover

[7]

[7]Several opening and closing tests should be conducted on each new pool, not only to ensure proper operation, but also to make certain the cover is straight.

“The automatic pool covers we install open and close at a rate of approximately 0.3 m/s (1 fps),” says Horwood. “Sometimes, holding the touchpad for a minute may feel like a long time, but closing the automatic cover in 60 seconds is much quicker than the 30 to 60 minutes it takes to close a manual or safety cover. It only takes 90 seconds to operate this 29-m (95-ft) long cover.”

The touch pad controller was located in the covered outdoor kitchen area on the end of the pool closest to the house. As a reminder to all pool dealers, all control pads must be located within full view of the pool for safety.

Thinking of the future

Horwood is also an advocate for the importance of inspecting and evaluating cover materials annually for wear and tear. He spends as much time as he needs with each customer to make sure he/she understands the benefits their new pool cover will offer.

“The business of automatic pool covers is growing exponentially in our area,” said Horwood. “At one point we were involved in all aspects of pool construction, but I found a passion for the automatic cover business and moved exclusively into installation 20 years ago. Back then, we put in eight covers a year; this year we are on par to install more than 100. Pool owners want the safety, convenience, and efficiencies of an automatic cover, and we are honoured to fulfil our client’s needs.”

Time commitment

To ensure the success of this project and, ultimately, his client’s satisfaction, Horwood’s crew made multiple pre-installation site visits with the builder, contractor, and homeowner over a two-year period.

“Not all cover installers are willing to make this time commitment,” said Horwood, “but by putting in this extra effort, our customer was more than satisfied with the outcome of his second pool and second cover installation with us.”

[8]Michael Shebek is owner and CEO of Automatic Pool Covers Inc.[9], a cover manufacturer based in Westfield, Ind. The business was started in 1979 as a pool cover installation and service company. Shebek has more than 20,000 hours of in-field pool cover service experience. He can be reached via e-mail at mshebek@apc-mfg.com[10].

[8]Michael Shebek is owner and CEO of Automatic Pool Covers Inc.[9], a cover manufacturer based in Westfield, Ind. The business was started in 1979 as a pool cover installation and service company. Shebek has more than 20,000 hours of in-field pool cover service experience. He can be reached via e-mail at mshebek@apc-mfg.com[10].

- Pool Patrol: http://poolpatrol.ca/

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/12/DSC_9758.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/12/BUNKER_1.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/12/CoverBunker.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/12/IMG_9024.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/12/IMG_9029.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/12/2-bunker.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2017/09/Shebek_Headshot.jpg

- Automatic Pool Covers Inc.: http://www.automaticpoolcovers.net/

- mshebek@apc-mfg.com: mailto:mshebek@apc-mfg.com

Source URL: https://www.poolspamarketing.com/trade/features/auto-cover/