Condominium’s outdoor living space gets a much-needed renovation

In the process of applying the PVC liner, the main drain, skimmers, inlets, and returns were also carefully terminated by using a custom-made PVC flange that was anchored with stainless steel fasteners to compress the membrane to the pool’s substrate. To ensure a perfect, watertight seal, the flanges are manufactured after being carefully measured by the installation crew. Once the flanges are ready, they are shipped from the factory to the jobsite for installation.

The depth markers, within the pool and on the deck surface, are also custom-made at the factory and applied on site.

Pool edge ‘sitting’ surface

During project discussions with the condominium association, it was discovered many residents enjoyed lounging around the pool, specifically sitting at the edge and dangling their feet in the water. Therefore, the client decided to replace the coping along the pool’s perimeter, as the initial installation was completed in a manner that left large gaps between the stones and the pool deck. Further, many of the stones were chipped and not sealed properly; therefore, it was recommended the renovation be completed using PVC flooring, which is made from a thick material that is soft and comfortable to sit on.

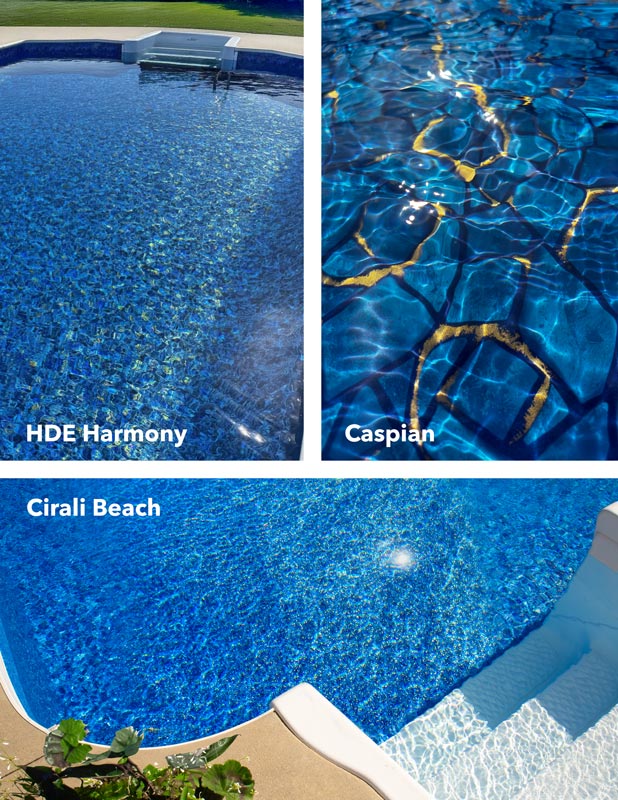

Designed for indoor and outdoor applications, this 85-mil, pre-felted PVC membrane is slip-resistant and independently certified to ASTM International standards for use in wet or dry conditions. Stabilizers and inhibitors prevent the material from fading due to ultraviolet (UV) light and chemical exposure, while biocides formulated into the material also make it algae- and fungus-resistant. The PVC surface would not only give the pool an updated, clean look, but would also make it easier for staff to maintain, using a mop, pressure washer, or sponge.

With these benefits in mind, the condominium association agreed to the installer’s recommendation to encapsulate the coping stones in the PVC material. Further, by using this product, it would allow the installers to heat weld the PVC pool liner membrane directly to the deck surface to ensure a watertight transition between the two products.

For this project, the decking surface was installed using additional foam between the existing coping stones and the PVC for added comfort. Much like the installation of the PVC pool liner, a strip of PVC-coated aluminum was screwed into the coping stones, along the perimeter of the pool, to attach the flooring material. Prior to installing the deck material, the coping stones had to be primed using concrete filler and silicone to seal any gaps, while the large space between the coping and the composite wood deck was filled using a silicone material to give the pool a clean finish.

The condominium association selected a grey flooring material for use around the pool perimeter, which complemented the pool’s blue interior finish.

The results

This project was completed last fall with the goal of having it tested and ready to open as soon as the weather warmed up this spring. Outdoor pool renovations like this one must be completed during temperatures in excess of 4.5 C (40 F). The PVC material is difficult to work with in temperatures below this threshold. Thanks to ideal temperatures, this renovation project was finished within 10 days. Once completed, the pool was filled and tested before being winterized.

By renovating the pool, the condominium association achieved its goal in replacing the tired, leaking vessel, breathing new life into the outdoor living space where residents can have fun with family, meet friends, read a book, or enjoy a poolside beverage for many years to come.

Steve Comstock is the president of RenoSys Corporation, a company specializing in commercial pool renovations based in Indianapolis, Ind. He has worked in the commercial aquatics industry for more than 38 years and has helped renovate thousands of commercial pools across Canada and the U.S. Comstock can be reached via e-mail at stevec@renosys.com.

Steve Comstock is the president of RenoSys Corporation, a company specializing in commercial pool renovations based in Indianapolis, Ind. He has worked in the commercial aquatics industry for more than 38 years and has helped renovate thousands of commercial pools across Canada and the U.S. Comstock can be reached via e-mail at stevec@renosys.com.