Pool builder teams with hardscape supplier to create feature project

The author was surprised when the homeowner shared the plans for their backyard (13 pages in total) along with the materials list, a number of contacts from the hardscaping manufacturer’s team, and, of course, the timeline (it had to be completed by Labour Day). At first, it was a little overwhelming for the author to have to deal with so many new faces on such a large project and, of course, the timelines were very aggressive considering they still had to apply for the pool enclosure permit. It is rare a project goes smoothly when there are so many new faces. That said, the opportunity to partake in this project was well worth the extra work.

To ensure the project operated smoothly, the author contacted the hardscaping manufacturer’s marketing director to discuss the installation, as well as to outline the expectations of each crew. A meeting was held so each team could identify various responsibilities and start planning the project. Naturally, this meeting was not like any other Pool Craft had been involved in, as the crew had never met, worked with, or even heard of any of the people they were about to be working side-by-side with on this job.

It is all in the details

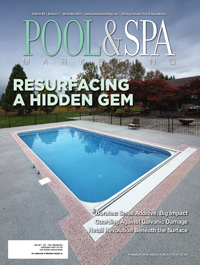

The pre-construction meeting was held on-site, which included the hardscaping team’s supervisor and director of education. Much of the discussion was based on the design and co-ordination of the various trades. As the images show, the backyard was fully equipped with a number of features, including a pool with a fire and water feature, firepit, cabana, and outdoor kitchen. A few suggestions were given to the designers on how to enhance the entertaining area and improve traffic flow. Based on the suggestions from all parties involved, updated landscape plans were required and arranged to be completed within the week. Thankfully, permit drawings were generated quickly and the excavation of the cabana footings were scheduled for early April with the pool excavation to follow.

Given all of the different components in this backyard, and the different materials being used throughout the entertaining areas, there was additional planning involved at each stage. Two to four stone options are typically used in a standard backyard project; however, seven different stones (with the colour selection in brackets) were incorporated into this backyard for the following components:

- Pool coping (beige cream)

- Cabana floor (grey nickel)

- Main patio (beige cream)

- Feature walls (beige cream)

- Accent patio by pool and outdoor kitchen area (hazelnut brandy)

- Step assembly (hazelnut brandy)

- Custom server (hazelnut brandy)

The installation process

The excavation of the pool is commonly the first item scheduled, however, in this situation the footings for the cabana, as well as all of the utility services, had to be installed prior to commencing any other work. There was a great deal of excavation work required and the fill had to be completely removed from the site so it did not impede any future work that was to be completed by other contractors.

Typically, multiple trades can work simultaneously, however, due the utility services being on the access side of the house, the cabana crew had to get their work finished first. Once the footings were poured, the excavation of the pool was next. The pool installation went smoothly, as the weather co-operated and excavation conditions were ideal. Pool Craft was given full access and had free reign of the backyard. During the pool construction phase, the cabana crew was able to start the framing process without interfering with the pool installation schedule.

This is not always the case, as some yards are larger than others and, therefore, more conducive to having multiple trades on-site at one time. Conversely, smaller properties usually do not permit multiple trades to work simultaneously. It takes a great deal of organization and co-operation from all of the trades for a project to run smoothly and on schedule. It is also crucial for each trade to respect each other’s wishes and work in harmony to ensure a problem-free operation. That said, everyone involved on this project was extremely respectful of each other, which created a great atmosphere on the jobsite.