How Ont. day camp found solution in weld-in-place membrane liners

Understanding membrane liner installation

Once the previous residential-style liner was removed from the pool at Hope Valley Day Camp, the pool’s surface was inspected and prepared for the new polyvinyl chloride (PVC) membrane. Fortunately, the pool’s interior surface was in decent shape and did not need any extensive repairs before installation.

Generally, before lining a pool with a PVC membrane, the surface needs to be inspected and any rough patches should be repaired if needed. Most pools can be prepared in a day or less. One of the main benefits of this thicker weld-in-place membrane is it makes the pool water-tight and eliminates any leaking problems because it completely encapsulates the pool structure.

Once the surface is prepared, a “geotextile fleece” is installed along the floor and walls of the structure. The geotextile is adhered to the pool surface before installation of the membrane, diminishing any surface cracks in the process. Once the lining is adhered, it acts like a pad under a rug.

Due to the geotextile fleece under the PVC membrane, this pool finish appeals to parents and kids alike as the surface is pleasing to the touch. It provides a soft barrier between the pool surface and the membrane—giving it a soft, slightly cushioned feel, making the floor more comfortable to stand on.

After the geotextile is installed, 60 mil thick, 1.8-m (6-ft)-wide rolls of PVC membrane is rolled out and heat-welded together on-site to ensure a perfect, smooth fit around the entire interior of the pool. Contrary to traditional residential style pool liners that are welded at the fabricator and stretched into place on the pool, PVC membrane liners are custom welded together on-site to match the pool’s configuration. These liners are cut, and custom fitted for steps, beach entries, safety ledges, and other in-pool features as well. Black material is also available to create racing lanes, transitions, and depth markers as needed.

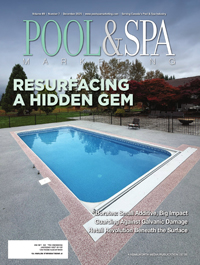

In the case of the Hope Valley Day camp, they chose a white PVC membrane and used black accents at the shallow end breaks and on the steps for safety. The author’s company worked together with RECA Vinyl Works, who installed the PVC membrane as part of the pool’s renovation.