How Ont. day camp found solution in weld-in-place membrane liners

Step-by-step renovations

In addition to the new 60 mil weld in place liner, the owners of the camp and pool also decided to remove the old residential-style fibreglass steps that lead into the pool with larger, commercial-quality steps. Due to RECA’s busy summer schedule, they worked directly with the facility manager at the camp to pour the new concrete steps.

“I had to walk the facility manager through how to pour the steps while also helping to keep the membrane installation going to meet the [project] deadline,” says Cuevas.

RECA worked directly with Easton to remove the old steps and build new, larger, concrete formed steps, which were also lined with the PVC membrane. The company also provided detailed instructions to guarantee the water-tight installation of the membrane over the steps.

“The hardest part of lining the new steps was to find a finishing point to terminate the vinyl,” says Cuevas. “I wanted the concrete to butt up to the membrane, to bring it directly over the steps, and to be able to waterproof the edge of the stairs.”

Luckily, this membrane is an easy interior surfacing system to modify on the job, allowing Cuevas to revise his plan for welding the membrane on the steps.

The new steps were an essential part of the success of this pool renovation. They are wider and make it easier for bathers to enter and exit the pool, not to mention far less slippery thanks to the PVC membrane. Additionally, RECA also installed a contrasting black PVC membrane along the edges of the steps to make each one more visible and safer for bathers when navigating in and out of the pool.

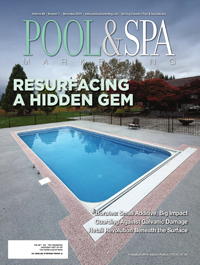

The newly renovated pool

The renovation of the Hope Valley Day Camp pool was a success, and it opened last summer on schedule thanks to the collective teamwork between RECA, the facility manager, and PVC liner membrane supplier.

The pool, being part of the camp, serves the local community, aged seven to 17, and now, since the pool has been fully renovated with a weld-in-place PVC membrane liner, it is almost as if it is new again.