Ocean water lagoon pools: Recreating a beach-like experience within a resort

by habiba_abudu | December 10, 2019 12:16 pm

By Juan Padilla

[1]

[1]Nestled between sapphire seas and dramatic desert landscapes, the Grand Solmar—located within the exclusive Rancho San Lucas private resort community, just north of bustling Cabo San Lucas in Mexico—is above and beyond ordinary. This 0.20-ha (0.5-acre) luxury resort offers its guests a massive lagoon pool with a lazy river, waterslides, several infinity pools, and multiple swim-up bars for casual dining.

The lagoon is essentially an artificial seawater reservoir filled with saltwater from the adjacent Pacific Ocean. It offers users a beach entry complete with sandy shores to mimic the feel of the ocean within the resort. That said, the location of the lagoon and its unique features posed multiple challenges to the construction and maintenance of the pool. From building on top of a sand dune to battling corrosion and sanitation issues associated with saltwater, this lagoon construction was anything but simple.

The concept

[2]

[2]Although the resort is located barely a few metres from the ocean, the rough waters of the beach were a deterrent for swimmers. Therefore, project developers conceived a lagoon pool design that would recreate the ambient landscape within the resort, complete with ocean water pumped directly into the lagoon from a well on the beach.

The resort has its own desalination plant that supplies the facility’s water, so a portion of the water is pumped directly into the pool from the same pumping system used by the plant. According to the project’s landscape architect, the lagoon provides users a beach experience and also doubles as a reservoir for the resort’s desalination plant.

Recreating the landscape

Baja California is essentially a desert next to the ocean, and building a pool in an arid zone is not easy.

“One of the biggest challenges was building this pool on top of (what is essentially) a sand dune,” says Xavier Alvarez, owner and CEO of Maxa Watershapes, and the co-designer, engineer, and builder of the lagoon. “Dealing with the sand and winds was a constant struggle, especially from October through February when the area experiences particularly high winds.”

[3]

[3]The lagoon has a water surface of 4560 m2 (49,083 sf) and can hold nearly 3,406,871 L (900,000 gal) of water. The design also flaunts varying depths—from beach entries in several areas to shallow zones where the water is only 153 to 915 mm (6 to 36 in.) high and a maximum depth of almost 3 m (10 ft) in others.

The pool was built using reinforced concrete walls lined with polyvinyl chloride (PVC) and then covered with a layer of shotcrete to protect the vinyl. A berm was also constructed around the lagoon to prevent sand from getting into the water.

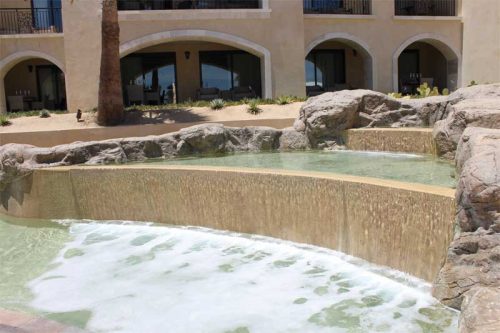

Multiple visual elements help accentuate the structure’s overall design—cascading rock water features spray and aerate the water, which simultaneously help with the circulation and flow. There is also a 3-m (10-ft) deep area with a diving tower. The two main water features—installed on opposite ends—provide the appearance of a natural waterfall and help to oxygenate the water. Due to the amount of water required to feed these features, four specialized pumps, offering a total flowrate of

9085 litres per minute (lpm) (2400 gallons per minute [gpm]), were installed.

Additional features adjacent to the lagoon that use non-saltwater include a show fountain with 14 bubblers and two spas—one on each end. Also, there are two waterslides and a children’s water play area next to the lagoon. All of these additional features require a separate equipment room far away from the main lagoon pump room to avoid long plumbing runs as well as to minimize the saltwater effects on the equipment. The water supply for these features, similar to the resort’s, comes from a huge desalinization plant.

Ocean water

[4]

[4]Using ocean water within the lagoon was another challenge on the project.

“To begin with, saltwater corrodes everything,” explains Alvarez, who has been in the aquatics industry for more than 20 years and has designed and built several hotel and residential pool and water feature projects. “From hinges and rails to pump room equipment, even wood is adversely affected by saline water.”

A lot of learning and adjusting was involved when the pump room design was conceptualized, especially as it had to be able to deal with the harsh saltwater; a maintenance and cleaning program was also devised for the lagoon.

“We couldn’t use the same type of pump room equipment on this project that we would typically use with a standard, non-saltwater pool,” says Alvarez. “We paid strict attention to selecting the correct mix of equipment that, not only would work in this situation, but would also have readily available parts in the area for future repairs and maintenance. Cabo San Lucas is almost like an island and is far from large distribution centres; therefore, we had to be sure we chose equipment that could easily be serviced with warranties.”

Water chemistry

The water chemistry of the ocean saltwater in the lagoon was another concern because the water had to be replaced entirely every 72 hours. As a result, it was difficult to balance the water because its pH levels were extremely high due to its alkalinity.

“With pH levels at 8 to 8.2, the sanitizers can become ineffective, so we decided to install two large specialized ultraviolet (UV) units that were 305 mm (12 in.) in diameter,” explains Alvarez.

The UV units have been highly effective at enhancing the power of the chemicals in the water, especially if there are longer stretches of time between the replacements of the water. It is also helpful during the rainy season.

“Our monsoons are like multiple small hurricanes,” says Alvarez. “Further, the winds introduce large amounts of dirt, sand, and rainwater that quickly alter the chemical balance of the pool water.”

Sand

When the lagoon first opened, the sand entering the reservoir was a serious challenge.

“Sometimes, we had to bring in an army of workers to help drain the pool, manually clean up all the sand in the vessel, and refill it with water from the ocean in less than 12 hours.”

This was a common scenario after rainstorms. Eventually, the pool builder introduced robotic cleaners into the lagoon vessel to reduce the amount of manual cleaning labour.

“Automatic pool cleaners were an excellent addition, but we soon realized we constantly had to replace equipment parts because the ocean saltwater corroded the metal components of the cleaners,” explains Alvarez.

Water flow

[5]

[5]Water flow and circulation were strategically planned keeping the size, shape, and varying depths of the lagoon in mind. To ensure proper circulation, the pool builder designed 87 floor returns fed with seven 152-mm (6-in.) lines, nine 152-mm (6-in.) anti-entrapment engineered floor suction lines, two 203-mm (8-in.) floor suction lines, eight 152-mm (6-in.) return lines for the water features, and six 152-mm (6-in.) skimmer lines. The flowrate was estimated at 18,443 lpm (4872 gpm), and the total water feature flowrate was 9090 lpm (2400 gpm). The circulation system was designed to provide for a fast turnover rate when required, such as moments after a storm or high winds. Under normal circumstances, the equipment functions at an optimal flowrate to keep the water quality in check.

“We also designed our own special skimmer returns,” says Alvarez.

In conjunction with the landscape architect’s directions, the custom skimmers were made of masonry to blend in with the lagoon’s esthetic design.

Equipment room maintenance

The lagoon’s equipment room comprises eight specialized horizontal sand filters, seven commercial plastic pumps (each pump measures 10 horsepower [hp]), three variable-frequency drives (VFDs), and two UV units. Both the filters and pumps require special maintenance routines due to the nature of the saltwater as well as the sand and silt that flows regularly into the lagoon pool.

Filters

The lagoon’s environment requires a lot of backwashing.

“One of the reasons why we really like using horizontal sand filters is because they have a hatch that allows us to visually inspect the media directly to see how dirty it is,” explains Alvarez. “Sometimes the sand looks like chocolate!”

The sand in the filters is backwashed weekly and manually cleaned almost every two months—though most of the debris tends to accumulate at the top of the filter. Sometimes a professional maintenance team may be required to manually clean the filters.

Pumps

The pumps have very few parts that corrode because even the motor on these units is totally enclosed and fan cooled (TEFC). However, there is quite a bit of plumbing both for the lagoon as well as the water features that are part of/included in its makeup, such as waterfalls and water bubblers.

Initially, the plumbing experienced an extreme ‘hammer effect’—there was violent shaking and the pressure was such it caused the plumbing connection to fail. To prevent this, the pool builder and equipment supplier worked in conjunction to install three VFDs, which would give the pumps a soft start, allowing the system to be pressurized gradually. Conversely, it would also allow the system to soft stop, decreasing the pressure and eliminating the hammer effect. In addition, the soft start and stop feature help protect the pump motor; thereby reducing the amount of maintenance and replacement of parts.

The author believes there has been a learning curve associated with the VFDs in this operation, as standard protocol in Mexico has always been to change the pump motor bearings annually, as part of a regular maintenance program. With the VFDs, it is important maintenance personnel understand they no longer need to open the pump motor housing. In fact, doing so will only reduce the life of the motor. In this case, the TEFC motors installed on-site along with the specialized pumps and VFDs ensure durability and reliability.

Variable-frequency drives

In addition to protecting the pumps and eliminating the hammer effect on the plumbing, the VFDs also provide added energy savings to the property owners. By being able to precisely dial the pumps to the required flowrate, the units are able to use less energy.

The variable-speed drives and UV units are fairly self-sufficient, too. The latter require very little maintenance outside of making sure their lamps are clean and functioning. The VFDs require minimal care and, in this salty environment, just need to be checked for corrosion and cleaned/repaired as needed.

The ‘lagoon’ experts

The lagoon at Grand Solmar has been operating for two years now. The pool builder paid great attention to every minute detail and ensured every kink was worked out of the system. In 2018, Maxa Watershapes handed everything over to the resort’s maintenance department and supervised as needed.

Due to the pool’s popularity, the owners of the property are planning to build an extension for the next phase of the project, which promises to be bigger and more dramatic.

“This project has provided us with valuable experience and knowledge on ocean saltwater pools,” explains Alvarez. “Because we do all the building and engineering, we are able to control the outcome and ensure success.

“We do everything in-house, and strive to gather knowledge about processes in multiple ways. Our customers trust us because we pride ourselves on being educated by attending various seminars and training courses, following all Association of Pool & Spa Professionals (APSP) codes. We also put emphasis on detail and, therefore; clients can expect superior results,” says Alvarez.

[6]Juan Padilla is a commercial and automation specialist for Pentair in LATAM (Latin American) & the Caribbean. He has been with the company since 2012, starting his career as territory service manager for LATAM. With more than 16 years in the industry, Padilla has held several positions including everything from service tech and installation manager to account manager. He can be reached via e-mail at juan.padilla@pentair.com.

[6]Juan Padilla is a commercial and automation specialist for Pentair in LATAM (Latin American) & the Caribbean. He has been with the company since 2012, starting his career as territory service manager for LATAM. With more than 16 years in the industry, Padilla has held several positions including everything from service tech and installation manager to account manager. He can be reached via e-mail at juan.padilla@pentair.com.

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2019/12/IMG_2339.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2019/12/IMG_2388.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2019/12/IMG_2408.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2019/12/IMG_9259.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2019/12/IMG_5145.jpg

- [Image]: https://www.poolspamarketing.com/wp-content/uploads/2019/12/JuanPadilla.jpg

Source URL: https://www.poolspamarketing.com/trade/features/ocean-water-lagoon-pools-recreating-a-beach-like-experience-within-a-resort/