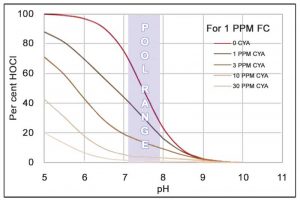

Practical approaches to cyanuric acid reduction in chlorine

Additionally, water treatment can involve the use of non-oxidizer additives. Enzymes, for instance, prove highly effective as they aid in breaking down complex molecular structures that might otherwise hinder chlorine’s effectiveness. When a cell structure is unravelled or deteriorated, this allows an oxidizer to easily reduce it from the water. Borate products can contribute to increased water clarity, though its bonding with calcium and other substrates. Additionally, borates can contribute to the stability of water balance by introducing a secondary buffering agent to the water. Further, maintaining low phosphate levels can provide relief in situations of reduced chlorine levels. Regularly cleaning filters to remove grease and oily deposits with dedicated solutions can also reduce the reliance on chlorine. Finally, the use of algaecides can be beneficial in diminishing the presence of algae.

What are the options for decreasing CYA levels?

Reducing CYA levels can be a challenge, as there are not many reliable methods available. While chemical treatments do exist, often enzyme based, following the precise instructions can be demanding for the person applying them. Another option involves using a portable reverse osmosis system (RO). These systems, at least currently, are large and usually expensive which are typically wheeled into place. When auxiliary hoses are placed into the water, RO uses high pressure to force water through a membrane which reduces everything in the water from calcium to cyanuric acids.

| Cyanuric Acid (CYA) Testing |

| 1. Sample collection. While obtaining a sample from a return may yield uncertain outcomes for pH and chlorine levels, it can offer a more precise measurement for cyanuric acid (CYA),particularly when water is drawn from both the bottom and the surface. When conducting an initial test following a period of water stagnation during the entire off-season, it is advisable to brush all surfaces and allow the water to circulate for 24 hours before obtaining the first sample. 2. Testing. There are three main methods for testing CYA. a. Test strips can help provide a general idea of CYA levels. b. A visual examination which involves introducing melamine or a comparable agent into the water. The mixture is then added to a chamber until a visual indicator disappears. This is fairly accurate, but some interpretation may be needed when reading the results. c. Photometers take the guesswork out of test results. As long as the machine is calibrated correctly and filled according to the manufacturer’s directions, the results should be fairly accurate. |

It is crucial to note that a significant portion, potentially up to 25 per cent, of the total CYA can settle in areas of the pool with poor circulation. Therefore, removing water from the lowest part of the pool becomes essential in diluting the water and reducing CYA levels. Recent recommendations within the industry say the use of aluminum sulfate (alum) may aid in CYA reduction.9 However, more studies are needed as there are no outside scientific papers to help draw a line between aluminum sulfate and CYA reduction. Regardless of the method chosen for water removal, it is important to replace water with elevated CYA levels with fresh water, specifically water with no cyanuric acid, to effectively address the issue.

It is worth considering most of the comments and recommendations provided here are focused on residential pool care. However, it is important to emphasize that cyanuric acid in water has not been linked to any documented cases of water-related illnesses. Unsafe water conditions typically arise from factors such as inadequate chlorine levels, poor water balance, and other subpar water care practices. Those factors will lead to issues like the proliferation of bacteria and virus and the growth of unwanted organics and other contaminants. These specifically point to algae and slimes, which have their own issues, can also lead to accidents caused by slippery pool bottoms. Managing elevated CYA levels is an integral part of swimming pool care, contributing

to the overall ease of water treatment

and maintenance.

Notes

1 See “Cyanuric Acid: Revised—September 2011” published by the Pool & Hot Tub Alliance (PHTA). For more information, visit www.phta.org/pub/?id=0838089D-1866-DAAC-99FB-D64EE07EA13F.

2 See note 1.

3 See “The Fundamentals of Chlorine Chemistry and Disinfection”, December 2007. For more information visit: https://dnr.wi.gov/topic/labcert/documents/training/CL2Chemistry.pdf.

4 See “Cyanuric Acid: CMAHC Ad Hoc Committee Report” published by the Council for the Model Aquatic Health Code (CMAHC) on Oct. 18, 2017. For more information, visit https://cmahc.org/documents/CMAHC_Ad_Hoc_Committee_Report_on_Stabilizer_Use._WAHC_2017-10-16_FINAL.pdf.

5 See “Oxidation-reduction potential” published by the New South Wales Government on Nov. 14, 2016. For more information, visit www.health.nsw.gov.au/environment/factsheets/Pages.orp.aspx.

6 See “Frequently Asked Questions about OxyChem’s ACL Chlorinated Isocyanurates” published by Occidental Chemical Corporation. For more information, visit www.oxy.com/globalassets/documents/chemicals/products/other-essentials/acl_faqs.pdf.

8 See “Minimum ORP Reading”, Model Aquatic Health Code, 4th Edition, 2023: https://cmahc.org/mahc_sections/776.

9 See “Aluminum sulfate for cyanuric acid removal” published by Service Industry News on Oct. 31, 2020. For more information, visit www.serviceindustrynews.net/2020/10/31/aluminum-sulfate-for-cyanuric-acid-removal.

Author

Author

Kevin Vlietstra is the technical director and regulatory specialist with Haviland Pool and Spa Products. He has been working in the recreational water industry for more than 25 years. Vlietstra can be reached via email at kevinv@havilandusa.com.