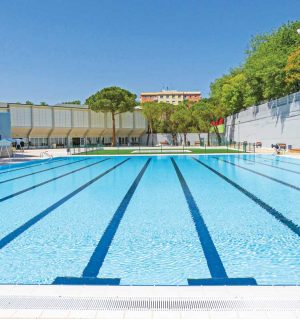

Renovating commercial pools with reinforced PVC

By Matthew Sands

As commercial aquatic facilities re-open after closures caused by the pandemic, managers and operators might have found themselves confronted with peeling, cracking, or leaking pools. A viable solution to these chronic problems is to line these commercial pools with reinforced polyvinyl chloride (PVC), as it is an ideal interior finish for pools and a complete waterproofing solution.

While price must always be taken into consideration, most facility managers and operators find reinforced PVC to be affordable over the long term. When considering this option, it is important for facility managers to consider the costs of refinishing or repairing their pools, compared to the cost of installing reinforced PVC. This finish does not require any maintenance year over year, and it can also solve underlying issues with a pool’s structure when the interior is encapsulated with reinforced PVC, as it can provide a complete watertight structure throughout the pool.

It is important for aquatic facility managers to understand that reinforced PVC is a pool interior that completely seals the structure of the pool and keeps it watertight, making it suitable for renovating existing pools and building new pools. Unlike concrete, reinforced PVC is not susceptible to deterioration from acidic water conditions. As many aquatic facility owners are aware, concrete pool interiors deteriorate over time due to the porous nature of the concrete. The acidity of pool water degrades concrete and requires painting and recoating of the surface to ensure the pool remains fully waterproof.

Commercial-grade reinforced PVC offers a long-term solution because it is not only thick and non-porous but also coated with a protective lacquer that resists chemical abuse, water absorption, and ultraviolet (UV) deterioration.

Once the reinforced PVC is installed, the surface underneath the pool can continue to shift and crack, but it will not affect the pool interior itself. Further, in many cases, this reinforced PVC pool interior often comes with a longer warranty than other pool interior options. In many cases, not only does the reinforced PVC interior pool finish help to solve a problem for an aquatic facility, but it can also make pool maintenance easier than a traditional concrete interior.

Practical with less maintenance

Reinforced PVC is a practical solution for pool interiors because it can be applied over most existing pool shells to renovate deteriorated pools or to quickly provide an interior finish for new pools. In fact, the installation of reinforced PVC can even be done over cold joints in concrete and is not susceptible to freeze-thaw cycles. In addition, this pool interior finish stabilizes the pool structure by preventing future water infiltrations. The reinforced PVC is also easily combined with gutter-system and PVC decking to create a seamless, watertight solution for the entire pool area.