Repair and refinishing solutions for fibreglass pools

Thermal spray pool finishes

This system utilizes a thermoplastic powder that is pneumatically forced into a very hot flame that melts the plastic powder, which then flows on the surface as liquid to form a thermoplastic coating once the heat is removed. There is no chemical cure or initiator utilization, meaning it is subject to embrittlement over time.

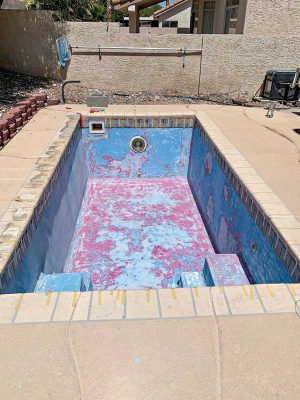

This new product was introduced to the pool industry more than five years ago. Unfortunately, it was overhyped and sold on unsubstantiated/exaggerated claims. It was offered as a product suitable for concrete use, but it never worked, resulting in all those applications failing, requiring expensive rework. In addition, it is only 6-mils thick and offers limited-service life.

In contrast, performance thermosetting resins are applied ± 80-mils thick. All legitimate products in the coatings industry are based on thermosetting not thermoplastic resins. Some pool professionals still use it on fibreglass pools, but after a few years in use, a deterioration has now come to light.

Many pool professionals signed up for the training program, but now have abandoned the material for more reliability. To avoid rework, high-performance epoxies, polymer composite resins, and modified gel coats offer the longest service life and peace of mind for contractors. It is best to avoid unproven coatings. In fact, the coatings industry is notorious for exaggerating product benefits, so it is imperative to proceed with caution when selecting a coating.

To this day, thermal spray coatings have not been recognized as a legitimate product in the pool industry as there are no written specifications and endorsements by aquatic consultants. A big problem in the pool industry remains the lack of body of knowledge for pool professionals to draw from, especially regarding polymeric materials, which could allow them to make a coating selection based on accurate information. It is easy for a manufacturer to make claims about their product.