Strategies for chloramine removal: Best practices for maintaining proper air and water quality at indoor pools

Non-chlorine oxidizers

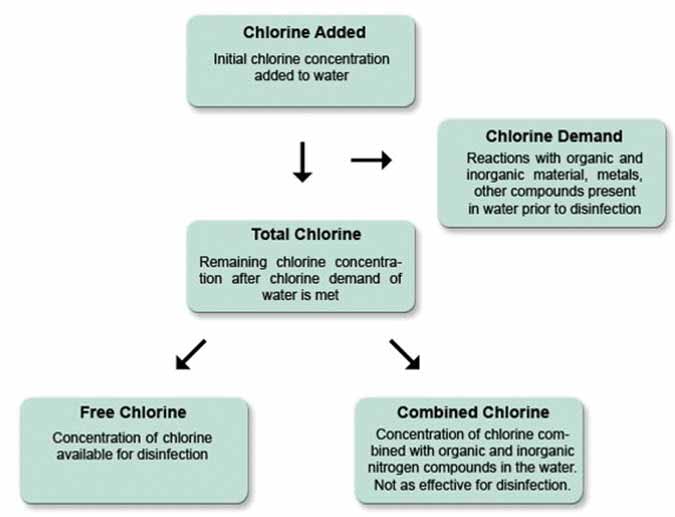

Non-chlorine oxidizers are oxygen-based oxidizers that will remove bather waste by destroying organic and inorganic pool contaminants. The active ingredient in these products is potassium monopersulfate (KMPS). They are odourless, fast acting, and completely dissolve in the water.

KMPS oxidizes chloramines as well as urea, the active ingredient in urine, according to John Wojtowicz, a well-known water chemist in the industry. It reacts very slowly with ammonia. KMPS’s lifetime in pool water depends on the quantity of oxidizable material. All things being equal, however, it is not nearly as sensitive to sunlight as chlorine. According to Wojtowicz, unstabilized chlorine is more than 90 per cent decomposed within a few hours, while KMPS is approximately 23 per cent decomposed per hour.

In Canada, these products are not regulated by the Pest Management Regulatory Agency (PMRA) as they are not disinfectants, which mean they do not kill disease organisms. They are purely oxidizers and have a place in maintaining a healthy pool water environment. As they are not chlorine-based they cannot create additional free or combined chlorine residuals nor can they increase the DBPs.

If using non-chlorine oxidizers, test kits require an additional reagent to remove the KMPS from the test sample. Facility managers/operators should contact their test kit manufacturer/provider for the proper reagent.

Superchlorination

Superchlorination is a strategy which involves adding sufficient amounts of chlorinating product to increase the free chlorine to a level in excess of 10 ppm, and maybe as high as 30 ppm in an attempt to burn out any and all contaminants that may exist in the water. However, in this process there may also be other compounds created from incomplete oxidation of microscopic cellular components. These DBPs can be removed using non-chlorine oxidizers or dilution.

Supplemental sanitizers

Ozone

Ozone is one of the strongest oxidizers a pool operator has in their arsenal. It is a supplemental sanitizer that will oxidize water contaminants in a chlorinated or brominated pool or spa/hot tub. With bromine it will regenerate the bromide ions back to active free bromine without the need to add additional chemical products.

In addition to its oxidative attribute, ozone is a micro-flocculent which means it polarizes the small suspended particles in the water so they are attracted to each other. This forms larger particles which are easier for the filter to remove.

Like most treatments, ozone has some drawbacks that need to be taken into account when considering this strategy. First, it is impossible to maintain an ozone residual as it quickly reverts back to oxygen in a few minutes. Second, it has a low solubility in water which means a lot of it gasses off into the air; therefore, a lot of ozone needs to be produced constantly to achieve the desired effect. Third, ozone production is dependent on temperature, humidity, wattage of the bulbs, and the configuration of the chamber. This means all units of the same size may not produce similar results.

When ozone is used in an indoor facility, the air within the complex should be monitored to be sure the ozone in the air does not exceed the regulated short-term exposure limit.

UV-C light

UV-C light supplemental sanitizing units can destroy chloramines and the ammoniated compounds that create chloramines and DBPs. It can also deactivate micro-organisms by destroying its DNA.

Medium pressure UV-C light units produce a wider spectrum of UV light which covers the necessary range for deactivating the micro-organisms and breaking the bond of amines from the chlorine molecule.

Advanced oxidation process (AOP)

This process works by combining ozone and UV disinfection. This system has the highest oxidative level of all the options currently available to pool operators. As with ozone and UV, this system is effective as a secondary or supplemental sanitizer and should be used in conjunction with a chlorine or bromine primary sanitizer. The benefit of this system, as with all supplemental sanitizers, is it allows free chlorine residuals to be maintained at or near the minimum levels required by regulation.

In AOP systems ozone is created using a corona discharge ozonator and a UV-C light is introduced to the ozonated water, which results in the creation of unstable (reactive) hydroxyl radicals (OH). These OH radicals only last for fractions of a second. The highly unstable radicals react with dissolved waterborne contaminants to oxidize them. Organic and inorganic chloramines, as well as micro-organisms, human waste, and other contaminants, are oxidized and chlorine demand is reduced.

Filter additives

In addition to destroying and preventing the off-gasses of chloramines by using different chemical and supplemental sanitizing systems, it is also important for pool operators to look at removing the ammoniated bather wastes before they have a chance to combine or early on in their transition from monochloramine through trichloramine.

Zeolites

Zeolites are a naturally occurring material. Their structure is irregularly shaped and courser than typical filter sand. This irregular shape gives it a surface area thousands of times greater than that of typical filter sand, making it capable of filtering finer particulate matter from the water.

Zeolites are negatively charged which gives them the ability to exchange ions with many different products including sodium and ammonia. When charged with sodium ions they have the capacity to exchange the sodium ions with ammonia ions to remove human contaminants from the water, eliminating the development of chloramines.

On a regular basis, based on the amount of bather load the water receives, the zeolites need to be soaked for 24 hours, with the filter system turned off, in a sodium solution to reverse the process. The ammonia ions are exchanged for new sodium ions and the ammonia ions are then backwashed to waste before turning the system back to filter mode.

Zeolites, like filter sand, need to be replaced on a regular basis (typically every one to four years of actual usage). The frequency is dependent of the amount of bather load the system is forced to work with rather than being based on the pool volume or its turnover rate.

Granular activated carbon (GAC) filter

This off-line filter system is installed as an effluent and will remove the chloramine water as it passes through. The effluent side of the GAC filter is attached to the main system prior to the clean filtered water going back to the pool.

While this is a simple system to install, the GAC will need to be replaced on a systematic basis as it will be used up by its collection of chloramines and the process is not reversible like the ion exchange with Zeolites.