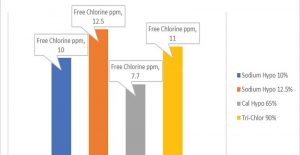

The domino effect in 2021: Stretching chemicals in the era of shortage

Secondary disinfection systems such as ultraviolet (UV) and ozone pool sanitizers are excellent at oxidizing and reducing the formation of combined chlorine. When using these systems, it also allows one to run their chlorine at much lower levels. Advanced oxidation process is one of the latest technologies which incorporates UV, ozone, and hydrogen peroxide to create hydroxyl radicals. Hydroxyl radicals are the most powerful way to destroy bacteria, algae, and contaminants in water. However, they are very reactive and last less than a second in the water. They can help to reduce the chlorine needed to sanitize the pool water, but these units are not a replacement for chlorine. Further, a minimum chlorine residual of either 1 ppm without CYA or 2 ppm with CYA is still needed. Any type of an additional oxidizer will help increase the effectiveness of chlorine in the pool water.

Balance is the secret

The secret to good pool chemistry and to the increase and effectiveness of chlorine in the pool is balance. Water that is balanced with proper CYA and borates will be the best quality with the least amount of chlorine needed. While standards are in minimum, maximum, and ideal, it is suggested to aim for the following target levels:

• pH 7.5

• Total alkalinity 90 ppm

• Calcium hardness 250 ppm (vinyl-lined or fibreglass pool) and 350 ppm (plaster pool)

• Cyanuric acid 30 to 50 ppm

• Total dissolved solids no higher than 1500 ppm over start-up

• Borates 50 ppm

In today’s world, one may not always be able to control the supply chain; however, what can be controlled is what chemicals are being used and how they are applied. By employing these techniques, homeowners and pool pros alike should see an improvement in water quality with less chlorine or specialty chemicals needed.

Terry Arko is a product training and content manager for HASA Pool Inc., a manufacturer and distributor of pool and spa water treatment products in Saugus, Calif. He has more than 40 years’ experience in the pool and spa/hot tub industry, working in service, repair, retail sales, chemical manufacturing, technical service, commercial sales, and product development. He has written more than 100 published articles on water chemistry and has been an instructor of water chemistry courses for more than 25 years. Arko serves as voting member on the board of the Recreational Water Quality Committee (RWQC). He is a Commercial Pool Operator (CPO) course instructor, a teacher of the Pool Chemistry Certified Residential course for the Pool Chemistry Training Institute (PCTI), a California Pool and Spa Association (CPSA) board member, and a member of Pool & Spa Marketing’s editorial advisory committee. He can be reached via email at terryarko@hasapool.com.

Terry Arko is a product training and content manager for HASA Pool Inc., a manufacturer and distributor of pool and spa water treatment products in Saugus, Calif. He has more than 40 years’ experience in the pool and spa/hot tub industry, working in service, repair, retail sales, chemical manufacturing, technical service, commercial sales, and product development. He has written more than 100 published articles on water chemistry and has been an instructor of water chemistry courses for more than 25 years. Arko serves as voting member on the board of the Recreational Water Quality Committee (RWQC). He is a Commercial Pool Operator (CPO) course instructor, a teacher of the Pool Chemistry Certified Residential course for the Pool Chemistry Training Institute (PCTI), a California Pool and Spa Association (CPSA) board member, and a member of Pool & Spa Marketing’s editorial advisory committee. He can be reached via email at terryarko@hasapool.com.