Fibreglass pool installation

Proper building techniques

Now with these misnomers put to bed, the following eight steps will discuss the basics of installing a fibreglass swimming pool. From site assessment, layout, excavation, and base preparation to craning, setting, backfilling, and plumbing the pool, these step-by-step details will help increase a pool builder’s confidence when entering this quickly growing segment of the pool industry.

Step 1: Assessing the site

A fibreglass pool is a large item that can span as much as 13.7 m (45 ft). Many dealers have been disappointed at the last minute after discovering the pool is not capable of being craned over the house due to obstructions such as overhead wires, branches (which may need permits to cut), or simply because the driveway will not withstand the crane’s weight. Most crane companies will visit the site free of charge to make sure the appropriate sized crane is used. In some cases, a builder may be able to use two excavators, one at each end of the pool, to walk it into the yard sideways.

Site access is also important when it comes time for excavation. Therefore, it is important to take the space between the houses into consideration when sizing the necessary equipment for excavation and fill removal. That said, one of the most important parts of the sales contract is customer acknowledgement that their neighbour is okay with the builder using their property with the understanding that there will probably be damage to their lawn.

If the neighbour changes their mind after the contract is signed, then it is up to your client to cover the additional costs of using smaller equipment.

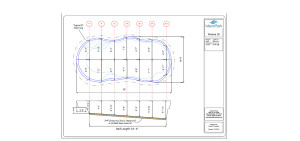

Step 2: Laying out the pool

Pool layout is completed by way of a dig sheet, which comprises a formulation of measurements describing a pool’s shape in 3-D. Once the layout is determined, run a string line down the centre where the pool is to be placed and measure off from each side.

It is a good idea to mark the string line with strips of tape to indicate the measurements beforehand, so when (not if) the orange paint markings disappear, the string line can be easily reinstalled to double-check the excavation. By accurately excavating the pool, it will save time and material costs. Remember to excavate a little larger area in the deep end to accommodate a 203.2-mm (8-in.) pipe for future dewatering.

The final grade of the pool is extremely important. If the builder is not providing landscaping and the customer has not yet secured a landscaper, then it is recommended the pool be installed so the top of the fibreglass is 25.4 mm (1 in.) below the homeowner’s existing patio. This will allow room for a coping stone (which is typically 50.8 to 76.2 mm [2 to 3 in.] thick) to be fastened to the top of the fibreglass lip, while still providing a slight fall away from the pool.

To ensure this is completed properly, it is important to consult with the client on the project’s final grade and place a benchmark that can be easily identified later to eliminate any discrepancies after the pool is installed. Using a laser level will simplify this process significantly.

Step 3: Excavating the pool

For those builders who have their own heavy equipment and the time to operate it, the excavation process can easily become their favourite part of the project.

For a pool builder new to the business, renting heavy equipment is recommended during the first year for two reasons: the ability to try different sizes and models, which will assist in the selection of the right equipment, and the winter will go by much faster when monthly payments are not required.

When pricing a project, remember to include the cost of dump sites as some (e.g. Toronto) can be as much as $80 per load, no matter the truck size.

When excavating the site, dig approximately 76.2 mm (4 in.) deeper to accommodate the base of the pool. Another advantage to installing fibreglass pools is during the spring when the ground is typically wet, water can be drawn out of the deep end via the dewatering pipe while working on a dry-solid base when using high performance bedding (HPB). This bedding comprises small washed stones approximately 6.35 to 8.5 mm (0.25 to 0.365 in.) in size.