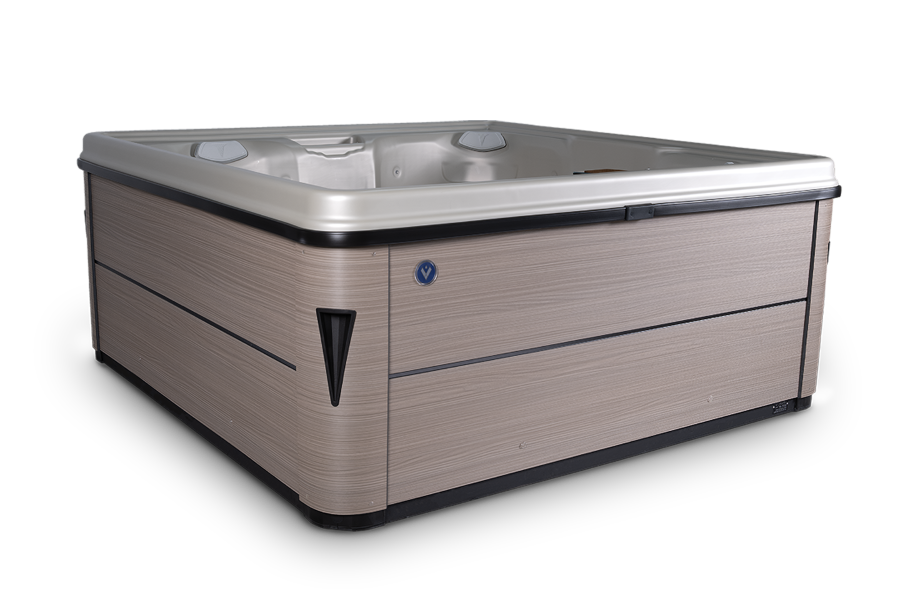

Hot tub cover specifications

By Aleta Mann

Replacement hot tub covers are custom made and not stocked by manufacturers the way they are in retail stores, which is why it is extremely important that specifications are accurate when orders are placed. Cover manufacturers rely on getting all the details when a product template is not available. Otherwise, the customer could face the costly prospect of paying for a remake.

Providing detailed replacement cover specifications can be a daunting task; however, this article will help simplify the process and ensure a good seal and an attractive fit.

It’s all in the details

The dealer should never assume his/her customer realizes every detail that is needed to fabricate a new cover. Most manufacturers will provide the dealer with an order form showing various options and shapes, in addition to which measurements are required. This form should be read carefully, as it will help to ensure no detail is missed.

It is also important to check with the manufacturer for available cover templates by providing, if possible, the make, model and year of the hot tub. More than one model with the same name may exist and a conscientious manufacturer will verify that the template matches the dealer’s needs. If a template is not available, measurements must be provided.

Made to measure

The first step is to measure the hot tub’s length and width. Measure across the centre both ways, from the outer acrylic lip to the outer lip on the opposite side. Always provide the size of the actual cover being ordered rather than the water-to-water measurement. Otherwise, the cover will fall into the hot tub.

If the cover is a rectangle or other shape in which the length differs from the width, draw the fold on the order form or submit a drawing. If the cover is circular, only the diameter measurement is required. Normally the fold is parallel to the short side, dividing the long side in half.

Measurements can also be taken from an existing spa cover. Keep in mind, however, this measurement will already be a little larger than the hot tub measurement. Therefore, it is extremely important to notify the cover manufacturer if the measurements were taken from the hot tub or the cover, as well as if any extra length or width has been added.

Measurements for inground hot tubs should include extra width and length—a minimum of 76.2 mm (3 in.) on all sides—so the coping will support the cover. Be sure to let the cover manufacturer know the measurements are for an inground hot tub and whether the cover will rest flush with the coping or if the hot tub is raised. It should also be specified whether the cover requires a skirt or straps—covers for inground hot tubs are often made without either.

Cover thickness measurements can also be taken from the existing cover. The thickest edge of the insert is usually the edge next to the fold. Measure the thickness from top to bottom, in addition to the thickness at the outer edge. Most hot tub cover foam is tapered; common tapers include, 101.6 to 50.8 mm (4 to 2 in.), 101.6 to 76.2 mm (4 to 3 in.) or 127 to 101.6 mm (5 to 4 in.).

Weather factors and energy savings should also be considered. The thicker the cover is the better—especially in colder climates. This also applies when selecting foam density, which indicates how tightly the foam beads are packed together within 0.09 m2 (1 sf) of foam. In other words, 0.68 kg (1.5 lbs) density means 0.09 m2 (1 sf) of foam would weigh 0.68 kg.