Determining TDH

Knowing this information, TDH can be calculated as follows:

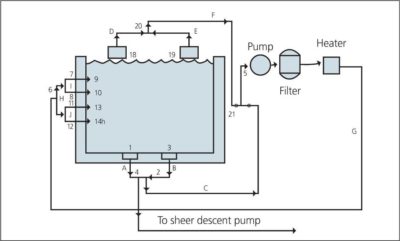

- Sketch the plumbing plan (see Figure 2) and label the starting and ending points of each segment. The segments are the pipes, fittings, and components between each point. It is best to start at the suction points and end at the return points.

- Set-up a calculation table or spreadsheet.

- In the table, start with a suction point and label the segment and starting point and pipe size. Note the total length of the pipe, type, quantity, and equivalent length of the fittings (see Table 2). Calculate the total equivalent length for each diameter and calculate the sum of the pipe and equivalent lengths for each.

- Calculate the head loss for each equivalent length of pipe and fittings.

- Enter the component head loss as found in Table 4.

- Complete steps three to five for each segment and calculate the head losses for each.

- For parallel segments, compare the total head and discard the lowest head segments.

- Add the total static head. Consider it as a segment between the highest discharge water level and the lowest suction level. If the pump is pulling from a skimmer, assume the water level in the skimmer.

- Sum the head of each segment, ignoring the discarded parallel segments. This is the TDH. Once this has been determined, the right pump can be selected that matches the flow rate and TDH.

For this design scenario, a three-quarter horsepower pump will meet the design needs. However, if the values are switched to 38.1-mm (1.5-in.) pipe, the TDH rises to 20 m (65.8 ft). In this case, a one-and-a-half horsepower pump would be required. The difference smaller plumbing makes in the efficiency of the pool system becomes quite noticeable.

Today, with more variable-speed pumps being installed on residential pools, flow rates must be considered a little differently. Throughout a 24-hour period, the system will still need to turn over the water volume at least two times. Notice in Figure 1, the 166.5 lpm (44 gpm) at 15.2 m (50 ft) TDH will operate around 2750 rpm. To reduce electrical consumption, the pump should be programmed to operate at half of the design speed during the peak and mid-peak electrical hours (12 hours) and one-and-a-half the design speed during off-peak hours (12 hours). This means the design will revolve around a 250 lpm (66 gpm) flow rate.

Using the original piping design to calculate a TDH of 15.3 m (50.3 ft) of head at 250-lpm (66-gpm) and a TDH of 7.28 m (23.9 ft) of head at 83.2 lpm (22 gpm), it becomes clear where the pump speeds can be set to achieve the desired 12-hour turnover throughout the day.

The process of planning and designing the piping and mechanical systems before commencing a project will provide the client with an efficient mechanical system that will save them money in electrical costs and chemicals.

Melissa Brown, P.Eng., is the president of Bonavista Pools in Toronto, a family-run, second-generation company her father Bob Brown started in 1969. She is a professional engineer who loves being in the field with her crew building pools. Brown can be reached via e-mail at melissa@bonavistapools.com.

Melissa Brown, P.Eng., is the president of Bonavista Pools in Toronto, a family-run, second-generation company her father Bob Brown started in 1969. She is a professional engineer who loves being in the field with her crew building pools. Brown can be reached via e-mail at melissa@bonavistapools.com.

![Table 2: Friction loss through fittings (equivalent pipe length in m [ft]) Table 2: Friction loss through fittings (equivalent pipe length in m [ft])](http://www.poolspas.ca/wp-content/uploads/2016/05/Plumbing_Table_3.jpg)

![Table 3: Component losses (metre[feet]) of head Table 3: Component losses (metre[feet]) of head](http://www.poolspas.ca/wp-content/uploads/2016/05/Plumbing_Table_5.jpg)

![Table 2: Friction loss through fittings (equivalent pipe length in m [ft]) Table 2: Friction loss through fittings (equivalent pipe length in m [ft])](http://www.poolspas.ca/wp-content/uploads/2016/05/Plumbing_Table_3-150x150.jpg)

![Table 3: Component losses (metre[feet]) of head Table 3: Component losses (metre[feet]) of head](http://www.poolspas.ca/wp-content/uploads/2016/05/Plumbing_Table_5-150x150.jpg)