Hydraulics and energy efficiency

Do the math

To calculate TDH, both gauge readings must be converted to a common factor, such as feet of head. In order to achieve this, one must multiply the vacuum gauge reading by 1.23 and pressure gauge reading by 2.31. Once both readings are converted, the sum is the TDH of the pool system.

(Pressure gauge reading x 2.31) + (Vacuum gauge reading x 1.23) = TDH

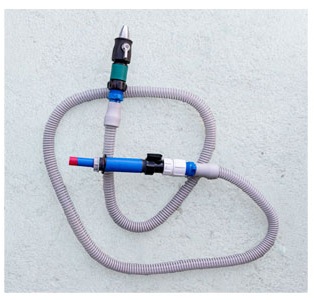

In residential pools, a vacuum gauge may not be present. In this case, it can be screwed into the drain plug of the hair and lint strainer, while the pressure gauge is installed on the pipe between the pump and filter. Once the system is turned on, with a clean filter in place, readings can be taken. Main drains can also be retrofitted to meet current entrapment regulations—these hydraulic calculations can be used to find the maximum flow rate based on the existing pool’s pump curve.

How resistance relates to flow

When TDH increases, flow decreases; conversely, as resistance decreases, flow increases. The goal is to increase flow with less resistance; this will require less horsepower to achieve the same circulation. The lower the horsepower, the less energy is consumed; thus, a more energy-efficient pump.

As the velocity of water travelling through a pipe increases, so does resistance, creating higher TDH and lower efficiency. In new pool construction, it is therefore prudent to consider increasing the pipe size to slow water movement. Swimming pool pumps are centrifugal, meaning they are designed to push water and challenged by pulling water. Easing the pump’s workload by increasing its size on the suction side will result in lower energy consumption.

Various energy groups are currently reviewing velocity and putting together recommendations on lower speeds. As an example, a 38-mm (1.5-in.) pipe at 2.1 metres per second (mps) (7 feet per second [fps]) can handle 163 lpm (43 gpm); by upgrading to a 50-mm (2-in.) pipe, 273 lpm (72 gpm) can be achieved at the same velocity. In a larger pipe, more water can be circulated with the same velocity, thereby decreasing resistance and reducing energy consumption. Furthermore, increasing the main drain suction from a 38-mm (1.5-in.) to a 50-mm (2-in.) main drain, and increasing skimmer(s) to 50 mm, will dramatically reduce resistance and friction loss.