Hydraulics and energy efficiency

By Connie Gibson Centrella

For decades, pool professionals believed over-sizing pumps and filters would give them a competitive edge in their pool presentations. Unfortunately, this supposed advantage has backfired significantly. The pool industry has been promoting excessive energy usage with little understanding of the cost to the customer and the planet. In the interest of environmental responsibility, professionals must take new approaches to equipment selection to create the most energy-efficient pool operations possible. Accurate hydraulics are vital to achieving this goal.

The objective of today’s pool professional should be to effectively marry pool volume, pipe size, velocity, pumps and filters. Proper sizing of pool equipment will not only facilitate an energy-efficient operation, it will also allow for proper circulation and chemical distribution. Pool energy workgroups across North America are convening to determine the appropriate hydraulic formulas to meet new energy standards and initiatives. The target is to achieve the desired circulation using the least amount of energy.

Understanding the science of hydraulics is the first step toward elevating products to meet demands of the energy efficiency movement. Getting back to the basics of pool calculations is a must. To size the new pumps, pool litres (gallons), turnover rate and litres per minute (lpm) (gallons per minute [gpm]) must be known, while pool piping and fittings must be taken into consideration to determine the entire circulation system’s total dynamic head (TDH).

Efficiency relates to flow and resistance

In lay terms, TDH is defined as resistance to flow. The entire loop around a pool comprises the total length of piping; friction losses generated by each fitting, value, filter, heater and chemical feeder are combined to compute TDH. The term ‘head’ is further modified by two factors:

- Whether the resistance is encountered on the suction side (suction head) or discharge side (discharge head) of the pump; and

- Whether resistance is caused by the standing weight of the water (static head) or the movement of water through the system (dynamic head).

In new pool construction, engineering of TDH can be determined by reviewing the pool plans. Velocity, pipe size, length of pipe and fittings each have a specific resistance, which can be determined using a series of calculations and then totalled to assess TDH. In many municipalities, building code officials are demanding these calculations be verified and approved prior to installation of a new pool. The bottom line is the TDH will determine the size of the pump, whether it is variable-speed, two-speed or single-speed.

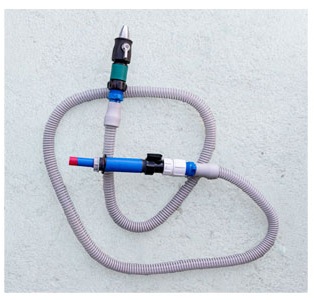

Retrofitting an existing pool is much easier. Obviously, pool professionals cannot simply look under decks to see piping and fittings. However, TDH can be estimated with some degree of accuracy by using two instruments—a vacuum gauge and pressure gauge. The vacuum gauge, located on the suction side of the system, measures friction loss on the suction side and is expressed in inches of mercury (Hg). The pressure gauge measures friction loss on the discharge side and reads in pounds per square inch (psi).