Independent testing performed on Latham Pool Products’ Coverstar automatic swimming pool safety covers has shown the company’s patented manufacturing technique to prolong cover webbing life and improve overall operation.

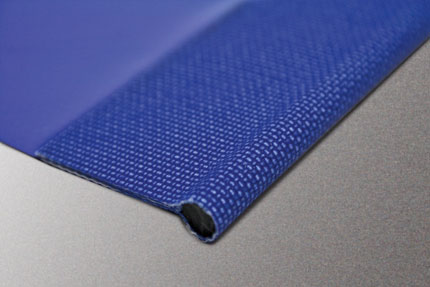

Rather than wrapping the webbing material around rope and sewing it to the cover, Latham, which has various locations in Canada and the U.S., uses a flexible polymer bead to bond the webbing to the cover fabric via heat seal. According to the company, this eliminates the rope from rubbing back and forth in the sleeve, which typically causes puckering when the cover is retracted. As pucker points rub against the tracks, the webbing fabric wears out.

During the independent research, Latham’s Coverstar-branded covers underwent several pull tests, which saw the webbing withstand, on average, a force of 204 kg (449.86 lbs).

“Our patented process of fusing the webbing, polymer bead and cover into one piece prevents the webbing from puckering and gives the cover its unique strength,” says Coverstar president, Doug Larson. “This is just one of many proprietary innovations that add to the durability and reliability of our automatic safety covers.”