Maintenance and troubleshooting tips for saltwater chlorinators

| A LOOK AT NON-RELATED SALT SYSTEM PROBLEMS |

|---|

| Typical complications that can occur in saltwater swimming pools/spas, which are not related to the electrolytic chlorine generator (ECG) are generally caused by environmental or operational conditions.Stabilizer Problem: Insufficient chlorine (Cl) production (outdoor pools). Solution: For outdoor pools, a stabilizer (cyanuric acid) should be added to help prevent the sun’s ultraviolet (UV) rays from breaking down free chlorine in the pool/spa. The recommended range is 50 to 80 parts per million (ppm), 30 to 50 ppm for oxidation reduction potential (ORP) controlled systems.Phosphates (PO43−) and nitrates (NO−3) Problem: High chlorine demand caused by excessive levels of phosphates and nitrates, which help algae grow. Solution: Lanthanum (La) and aluminum (Al) based specialty chemicals are two effective treatments for removing phosphates from pool/spa water, while ridding the pool/spa of nitrates requires diluting the water. As a rule of thumb, always treat the algae first, then deal with phosphate issues. The reason for this is algae will release more phosphates into the water as it dies off, which means the pool/spa will require another phosphate treatment.Sodium thiosulfate (Na2S2O3) Problem: High chlorine demand caused by adding too much chlorine neutralizer. Solution: Chlorine neutralizer is a potent product used to lower chlorine levels (typically in commercial pools). Performing a shock treatment (mixing a large amount of sodium hypochlorite [NaOCl] into the water) will satisfy the chlorine demand and bring the pool/spa back to normal operating conditions. Sodium bromide (NaBr) |

General maintenance advice

Testing chlorine levels periodically will help to ensure the ECG is properly adjusted. Bear in mind, overall water chemistry should also be routinely tested to ensure the water is properly balanced. By using the Langelier Saturation Index (LSI), a calculated number used to predict the calcium carbonate (CaCO3) stability of water, the water’s corrosive or scaling tendencies can be determined.

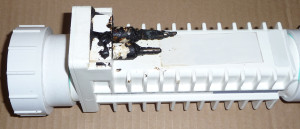

Control unit

Each manufacturer provides different types of diagnostics and control features on its ECG control units. Some provide digital displays, while others provide light-emitting diode (LED) displays. Warning messages and error codes displayed on the control unit should be utilized, along with the system’s owner’s manual, to diagnose problems. Those who are comfortable working with electronics can inspect the circuit boards for damaged fuses and burnt boards.

Watch for scale

The cell should be removed periodically and inspected for calcium scale formation on the titanium blades. Scale formation is the worst condition for the cell to operate under as it depletes the Ruthenium Oxide coating the quickest.

Scale forms under two conditions—malfunction of the cell’s self-cleaning operation (reverse polarity) and improper water chemistry. One way to determine the cause of scale formation can be determined by how quickly it is forming. For instance, a cell showing scale buildup within one week of operation is typically a system where the reverse polarity function is not operating properly. If scale forms after more than two weeks, it is generally water balance related. Removing calcium scale buildup on the cell is discussed later.

Other reasons, which may cause the cell to fail, include improperly connected or damaged cell cords or expired cells.