Maintenance and application techniques for cement-based pool finishes

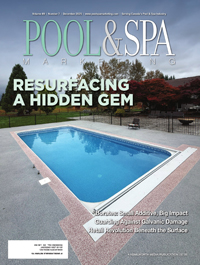

Pebble/exposed aggregate

Pebbles are embedded throughout an exposed aggregate finish, which is also mixed with cement and water. These finishes have proven to be the most reliable and esthetically pleasing on the market today as they have an extremely natural appearance and are available in a wide range of colours.

As the pebble is exposed in a wash process, the stone material that comprises the pebble is chemically inert; therefore, the finish will not react to varying pool/spa water conditions, making it less susceptible to attack or alterations in appearance.

Pebble aggregates are rated seven on the Mohs scale with an absolute hardness rating of 100, making this finish more than 10 times harder than a traditional plaster finish. That said, these finishes should be applied by a trained technician.

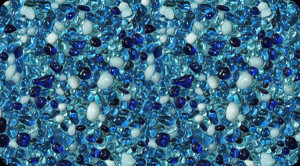

Glass beads

Glass beads are a unique architectural pool finish that creates added light refraction. These finishes contain small, reflective solid-glass spheres that are locked into an aggregate mix of polymer modified cement. They are combined with selected coloured aggregates, which mirror light under the surface of the pool’s water and create a vibrant, sparkling finish.

Similar to exposed aggregate, glass bead finishes should be applied by a professional.

Depending on the type of glass, the Mohs hardness scale rating will vary between five and seven, while the absolute hardness rating can fluctuate between 45 and 100.

Pricing for interior pool finishes will vary depending on the material used and application process; therefore, ask the applicator about their processes and warranty. Be wary of the lowest price as taking shortcuts can affect the quality and longevity of the pool’s finish.

Application techniques

To apply a cement-based pool finish, it is important to follow the manufacturer’s directions. There are two ways to apply a pool finish, manually (i.e. by hand) or pneumatically with a pumping rig.

Hand-finished

Applying a pool finish manually typically requires a 0.1-m3 (6-cf) mobile mortar mixer, which is capable of making approximately 180- to 226-kg (400 to 500 lbs) batches of pool finish materials. Generally, the mixer is placed as close to the pool as possible, making it easier to pour the wet mix into a wheel barrow, where it is then shoveled into buckets and carried into the pool for application. At this point, labourers supply small amounts of the mixture from the plasterers ‘hawk’ (i.e. a tool used to temporarily hold the plaster) to their trowel to apply the mixture onto the pool surface.

Manually applied pool finishes should be completed by highly skilled operators as the potential for cold joints (i.e. the juncture of fresh stucco application adjacent to set plaster) and inconsistent batches (mixes) can affect the finished appearance.