Making a case for better hot tub cover fabrication

The answer

Fortunately, these low-end, entry-level hot tub covers are not the only option for hot tub owners. Quality-built hot tub covers are readily available from a handful of manufacturers. That said, retailers can use the following guidelines to determine what they should look for when sourcing a quality hot tub cover supplier/manufacturer. Offering a quality product helps ensure customer satisfaction and return business.

Step 1: Foam density

The most important aspect of any hot tub cover is the foam. It is also an expensive component of the cover. The easiest way to bring down the cost is to lower the foam density; therefore, make sure to ask what foam density the manufacturer is supplying. In the past, the standard was always 0.7 kg (1.5 lbs) and high-end covers were more than 0.9 kg (2 lbs). Today, however, there are low-end hot tub covers on the market that are 0.45 kg (1 lbs) or less.

Step 2: Taper/thickness

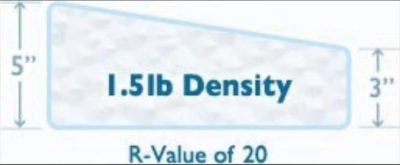

The foam density is one thing, the taper is another. This relates to the thickest to narrowest part of the hot tub cover (from the middle outwards). Low-end covers typically have a 76- to 51-mm (3- to 2-in.) taper and, in most cases, will not last a full year, especially after a harsh winter. The cover is a hot tub’s only line of defense when it comes to wet heavy snow, ice, rain, and wind. In some cases, the cover may need to support all of this dead weight for several months if the hot tub is not used during the winter.

With this in mind, a 102- to 76-mm (4- to 3-in.) taper should be the new standard, as the taper on most low-end hot tub covers is simply not enough. In fact, 152- to 102-mm (6- to 4-in.) and 127-

to 102-mm (5- to 4-in.) tapers are now available from all hot tub cover manufacturers.

Step 3: Plastic polywrap

The poly plastic film used to wrap and protect the cut foam (used inside the hot tub cover) from moisture damage is extremely important. Once the foam starts taking on water it will soak it up and retain it like a sponge. This will hinder the hot tub cover’s ability to perform its primary function—preventing evaporation and heat loss.

Essentially, once the foam has become compromised the entire hot tub cover is ruined. Therefore, ask the manufacturer what the foam is wrapped in, how thick is the film, and if the foam can be double-wrapped. The best option is to use a 0.0254-mm (4-mil) wrap or, for a small fee, have the foam double-wrapped.

Step 4: Vinyl

The vinyl that encases the polywrapped foam is essentially the cover’s skin. It is what takes all of the external abuse (e.g. sun’s ultraviolet [UV] rays, rain, wind, sleet, and snow). Therefore, make sure the hot tub cover supplier is using a properly freeze-tested and UV-stabilized marine-grade vinyl.

If poor quality vinyl is used, the skin will fade quickly, dry out, and eventually crack and dissolve. Once this happens, the polywrapped foam will be exposed, resulting in the failure of the hot tub cover.