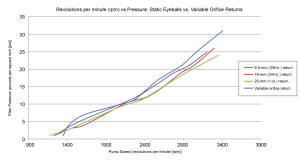

Revolutions per minute (rpm) versus pressure

In terms of rpm versus pressure (see Figure 2), research shows as the pump speed/flow rate increases, so does the pressure on the system. This increase in pressure can result in the reduction in the life expectancy of the filtration system. The added pressure, and restriction it creates, is directly related to the size of the pool return. The smaller it is, the greater the restriction as flow increases. Further, this restriction also demands higher speeds (rpm) from the pump for a given flow when compared to a larger pool return.

Typically, a pump will operate at low-flow/low-speed (rpm) for the majority of its life. However, when there is a need for the system to increase its flow/speed (rpm) (e.g. during a heating cycle), and a variable orifice pool return is installed, it will open, based on the flow rate, and reduce unwanted restriction on the system. This also allows for greater flow at lower pump speeds. Further, overall stress on the system is reduced and less equipment failures are likely to occur.

For example, at a flow rate of 151 lpm (40 gpm), the water pressure through a 9.5-mm (3/8-in.) pool return is 0.15 MPa (22 pounds per square inch [psi]), while the water pressure through a variable orifice return would be 0.10 MPa (13 psi).

For example, at a flow rate of 151 lpm (40 gpm), the water pressure through a 9.5-mm (3/8-in.) pool return is 0.15 MPa (22 pounds per square inch [psi]), while the water pressure through a variable orifice return would be 0.10 MPa (13 psi).

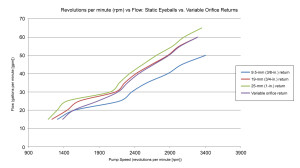

Revolutions per minute (rpm) versus flow

When looking at rpm versus flow (see Figure 3), research shows as the flow/speed (rpm) of the system increases, the less efficient a smaller pool return becomes at providing a given flow. The smaller the orifice, the greater the restriction and the harder the pump needs to work.

On the other hand, a variable orifice return will self-adjust, allowing the system to operate more efficiently (use less energy) when obtaining a given flow rate at a lower speed (rpm).

On the other hand, a variable orifice return will self-adjust, allowing the system to operate more efficiently (use less energy) when obtaining a given flow rate at a lower speed (rpm).

Sean Walsh is the vice-president of research and design for Eco-Blu Pool Components LLC, a manufacturer of various pool components in Forty Fort, Pa. Walsh has a degree in environmental science and has 11 years of service and construction experience in the swimming pool and spa industry. He can be reached via e-mail at walsh.sean@ecobluweb.com.

Sean Walsh is the vice-president of research and design for Eco-Blu Pool Components LLC, a manufacturer of various pool components in Forty Fort, Pa. Walsh has a degree in environmental science and has 11 years of service and construction experience in the swimming pool and spa industry. He can be reached via e-mail at walsh.sean@ecobluweb.com.

Zach Schultz is the director of operational planning and sales for Eco-Blu Pool Components. He has seven years of experience in the swimming pool and spa industry and is an expert in marketing, advertising, and sales. He can be reached via e-mail at schulz.zach@ecobluweb.com.

Zach Schultz is the director of operational planning and sales for Eco-Blu Pool Components. He has seven years of experience in the swimming pool and spa industry and is an expert in marketing, advertising, and sales. He can be reached via e-mail at schulz.zach@ecobluweb.com.