NSF International evaluates the performance, and health and safety of swim spas

Swim spa systems

In 2012, NSF introduced the first comprehensive specification to evaluate the performance, and health and safety of every swim spa component.

The standards were created to meet the needs of the different stakeholder groups, most notably the public health and building officials, product manufacturers, and facility operators who were unsatisfied with existing industry standards and products that were considered inadequate for public-use spas/swim spas. The existing criteria were flawed, allowing the use of outdated plumbing materials, inappropriately sized steps, lack of slip-resistance testing requirements, insufficient water filtration, and circulation rates among other issues.

The NSF criteria address these and many other important aspects of the evaluation and testing of these spas. The new specification, CCS-11804: Component Certification Specification for Public Use Spa, Swim Spa, Hot Tub or Related Equipment, combines elements of more than 16 national standards and test protocols to create one all-encompassing standard. It clarifies and simplifies the required testing and evaluation process for product manufacturers to better meet the needs of health officials and recreational water facility operators. CCS-11804 testing and evaluation criteria include the following:

Material evaluation

Verifies water contact materials meet regulations for corrosion-resistance and toxicological health and do not leach harmful contaminants into the water.

Spa shell integrity

The spa shell is required to undergo chemical and performance testing to evaluate the unit for deflection, impact resistance, chemical resistance, durability, and strength.

Electrical safety evaluation

Confirms testing and certification of the spa system meets the requirements of Underwriters Laboratories (UL) UL1563: Electric Spas, Equipment Assemblies, and Associated Equipment.

Accessibility and safety features

Evaluates and tests the effectiveness of safety features including floor slope, floor-and-step slip resistance, step dimensions, depth markings, handholds, and railings via ASTM F462: Standard Consumer Safety Specifications for Slip-Resistant Bathing Facilities.

Performance testing

Most of the equipment used in the spa/swim spa must be NSF/ANSI Standard 50 certified (or tested and certified to other criteria) for use at the spa system’s flow rate.

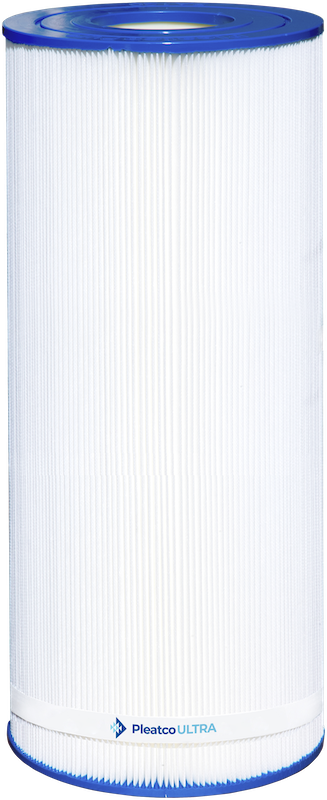

Filtration and water chemistry

Verifies the rate of water circulation and turnover to ensure they meet high performance levels. Further, quantification of chemical/supplemental treatment systems and water skimming capacity and particulate filtration systems to assure they perform at a high level and effectively capture contaminants from the water.

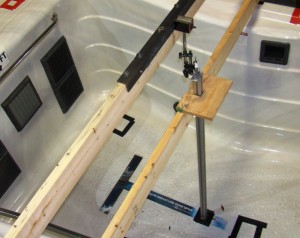

Suction fittings and systems

Entrapment safety tests are performed on the entire swim current or exercise system. This involves evaluating fasteners, ultraviolet (UV) exposure and strength testing of the suction fitting system materials, hair and body entrapment, and various load testing via in-position testing of the complete system.

These specifications were developed over many years by working with a leading swim spa manufacturer, component manufacturers, and public health officials to help specifiers assess pools and spas suitable for commercial or public facilities. Sufficient flexibility is permitted to acknowledge variations in functional design such as different water treatment and skimming systems, as well factory designed and built versus factory designed systems intended for on-site installation with a separate skid pack comprising circulation, filtration, and treatment system components.

In 2012, Master Spas’ Michael Phelps Signature Spas (MPRX 17 and MPRX 18) were the first to earn NSF International certification to the CCS-11804 protocol. In addition to testing swim spas at NSF world headquarters, an audit of Master Spas’ manufacturing facility in Fort Wayne, Ind., was also conducted to verify quality and control standards as well as to confirm only authorized materials and components are used in the manufacturing of the swim spa.

Additionally, as with any certified product, annual unannounced facility audits and periodic retesting will be conducted to ensure ongoing compliance. This procedure will be standard practice for all manufacturers seeking certification under the new NSF/ANSI 50 public spa and swim spa requirements when they are finalized and published in NSF/ANSI 50.