Online cost calculators: The first step to reducing pool operating costs

Using the cost calculator for proposals

Using an online cost calculator is the first step in getting an aquatic facility to consider upgrading or retrofitting its mechanical room. It is an easy tool that can be used to close a deal with a facility that might be hesitant in replacing its outdated equipment. By showing operators how much money can be saved in energy costs alone, it can be a game changer with respect to approving any mechanical room upgrades. When electricity costs can be reduced at an aquatic facility from $1000 to $300 per year, the question then becomes, what will the facility do with the extra money?

Similar to what was experienced in San Antonio, several years ago, the city of London, Ont., hired an auditor to perform a cost-benefit analysis of reducing energy consumption on all city-run facilities, which included six aquatic facilities. The calculations were powerful enough that the city decided to retrofit a myriad of systems to lower energy consumption, including the installation of VFDs on all pumps used by the municipal pools.

Hollandia Pools, also of London, performed all of the retrofit work at the aquatic facilities, which included the installation of VFDs and ultraviolet (UV) disinfection systems; the latter was included with the intention to help reduce pool chemical consumption as well.

Another factor in the city of London’s case was the ‘redundancy’ designed into all of its aquatic facilities. For instance, the city mandates two pumps on every body of water. One pump is in operation on the pool and the other acts as a backup. Both pumps are plumbed and ready to go and they switch on/off between pumps every month. As a result, Hollandia installed one VFD on every two pumps. For example, one of the city’s aquatic facilities contains two bodies of water—a lap pool and a wading pool. Each has two pumps—one operational and one in reserve—and they switch the pump being used on a monthly basis.

Hollandia Pools & Gardens’ Richard Deakins says it is important to note the VFDs should always have a flowmeter to keep the VFD properly calibrated as the filtration system loads. Flowmeter automation is an integral part of the VFD’s functionality. Without it, the VFD is just an expensive light switch.

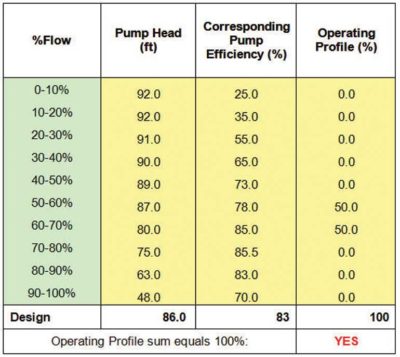

Deakin says a typical pool in the city of London is classified as ‘Class A,’ which means it requires a turnover rate of six times per day or once every four hours. (The city requires its pools to operate 24-7). During this period, the pumps are pulling and pushing water through the filtration system and as the filters get dirtier, the pumps need to speed up or slow down to meet the flowrate requirements. By putting a flowmeter with the appropriate set points on the VFDs, they can then be controlled by the flowmeter readings.

As a result of this project, the City of London recognized an overall cost savings of 30 to 60 per cent on energy consumption.

Deakin understands the power of cost calculators and regularly shows prospective customers the positive results achieved with his previous customers. In fact, the cost calculator has become so integral to his business that he has the program installed on his laptop.

“I look at the pump sizes, flowrates, etc., and I have the client pull out their electrical bill to enter the rate which they are being charged per kilowatt hour,” says Deakin. “It’s very easy to show them a comparison of what they are paying now and how their costs would decrease should they install a VFD and flowmeter on all their pumps.”