Popular sanitation method makes its way into the hot water market

How do salt systems for hot tubs differ from standard units?

Traditional hot tub water needs to be properly balanced to keep the hot tub free from damage (e.g. scale and corrosion). The elements of balanced water are: calcium hardness, total alkalinity (TA), pH, and total dissolved solids (TDS).

Calcium (Ca)

In traditional hot tubs, calcium hardness levels should be maintained between 150 and 400 parts per million (ppm). In saltwater hot tubs, the calcium level can be maintained more towards the lower end. Some manufacturers recommend calcium hardness levels be no higher than 50 ppm. In these cases, they provide a device for lowering calcium hardness with the salt generating system. Higher levels of calcium in salt systems can cause scale to form on the metal cells and reduce sanitizer output. This is a specific problem in hot water environments because calcium precipitates into a solid much quicker.

Total dissolved solids (TDS)

Because of the high TDS and the production of sodium hydroxide in the system, the total alkalinity will also increase. Therefore, the total alkalinity in a salt system can be maintained at a lower level as well. Many manufacturers of salt systems recommend no more than 80 ppm of total alkalinity. Normal total alkalinity levels usually range between 80 and 120 ppm.

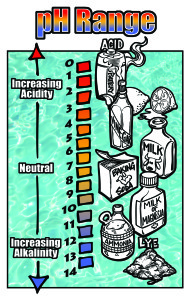

pH

pH in salt pools tends to stay fairly balanced due to the fact an acid and base are produced and mixed from the reaction of the cells. The ideal pH for salt systems is 7.4. High TDS in a standard hot tub is undesirable. However, in salt systems there will be an increased TDS level from the sodium. This is beneficial for the creation of the sanitizer. TDS of the fill water should be tested and written down before adding salt or sodium bromide to the water. TDS should be retested after adding salt or sodium bromide. Afterwards, TDS should be tested monthly. Whatever the TDS reading is, the difference should be subtracted between the fill water and the test after salt or sodium bromide was added. If the TDS reading is 1500 ppm over the fill water, then it is time to drain and refill. The recommended TDS salt level is 1000 ppm.

For both sodium chloride and sodium bromide systems, the salt levels can run anywhere between 1000 to 2000 ppm. Therefore, it is important to always check the manufacturers’ directions for details on proper salt levels.

Dealing with metals

In salt water pools there is a greater propensity for corrosion and staining from metals. These metals can be in solution in the source water used to fill the pool and or hot tub. Some examples of dissolved metals that can be present in water include: iron (Fe), copper (Cu), and manganese (Mn). Also, depending on the type of system, there could be some copper present that could corrode. The reason for this in saltwater hot tubs is due to galvanic corrosion. In a high TDS solution such as a salt system, the water is highly conductive. This means electrical charges travel more quickly and efficiently.

With the presence of a low-voltage form of electricity in solution with dissimilar metals there is a greater potential for staining. As pointed out previously, most salt systems use platinum or titanium for the anode and cathode cells. Both of these are high on the list of noble metals. This means they are the least likely to corrode in an environment where other metals may be present. Iron, copper, and manganese are all lower on the list of metals; therefore, if any of them are present in the water of a hot tub using a salt chlorine generator, they will act as a sacrificial anode and corrode more readily.

The stains from galvanic corrosion of these metals will appear brown, turquoise, black, and purple. The use of metal sequestering chemicals can help, along with the use of a zinc anode in the system. Zinc is one of the lowest grade metals on the list of noble metals so it will corrode more readily without staining surfaces.

What else is needed?

Saltwater hot tubs actually should allow for fewer chemicals needed to maintain proper water quality. Slightly more acid may be needed to keep total alkalinity levels from drifting upwards. Also, high levels of phosphates (PO43−) can cause interference in salt systems that reduce the output of sufficient sanitizer. For this reason, monthly phosphate testing should be performed.

Phosphate levels should be maintained below 500 parts per billion (ppb); 200 ppb is ideal. Phosphate removers are available to rid excess phosphate that may be present in fill water. Also, extra metal protection is needed in salt systems to ensure any metals in source water do not drop out and cause staining; therefore, be sure the metal product is a phosphate-free formula. Clarifiers can help to floc small suspended particles and keep water clear as well as help keep the cells cleaner.