By Farheen Sikandar

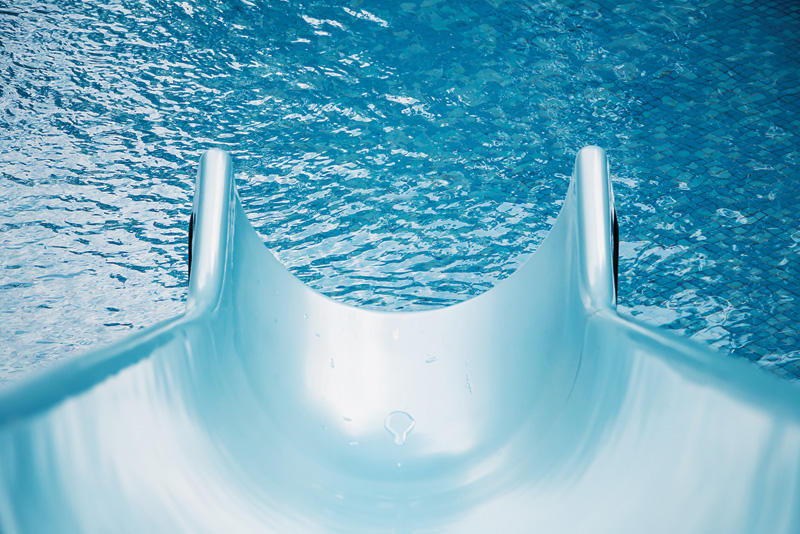

Inground slides are a solid solution for customers looking to spruce up their pool area and background space. Unique and functional, they are the perfect element for summer fun at home.

There are many factors to consider and explore with inground slides. Whether it be tubed or not, will it have stairs accompanying it, or will it be flushed in with the cast concrete design? What will the height be? Will it offer a straight fall or a 360-spin? Will it be removable or a permanent feature?

Offering customers customized pool slides can be an exciting upsell. Here are elements to consider.

Design and dimensions

To begin, it is essential to determine the desired dimensions of the slide and the available space within the customer’s environment. Pool slides can range from a minimum height of 0.9 m (3 ft) to exceeding 4.2 m (14 ft). A slide’s height is influenced heavily by its design, which may include various styles such as straight, curved, spiral, tower, and helical configurations.

Tower slides may require an additional platform for added height. The slide’s design will also impact its width, whether on the narrow side or wider. Flexible styles also allow for a multi-user design, such as double slides. Standard inground residential slides have a width of 0.6 to 0.76 m (2 to 2.5 ft).

The slide’s length also varies based on the design. A straight slide may be 2.4 m (8 ft) to 3 m (10 ft) long, while a curved or spiral slide could be 3.6 m (12 ft) or more.

Flume design is also essential; this means having a smooth, curved surface with a gradual angle to prevent users from getting friction burns.

Materials and design

Common materials used for inground slides are fibreglass, polyethylene, vinyl, stainless steel, and even concrete. For most playgrounds, stainless steel is the most common material.

Most custom inground slides are rotomoulded, a manufacturing process called rotational moulding. In this case, the material, plastic powder, is placed in a heated mould and rotated slowly until it melts, disperses, and sticks to the walls of the mould, forming a hollow object. This versatile technology is used for toys, containers, outdoor furniture, and more.

Each of the materials mentioned offers a range of benefits. For example, fibreglass is durable, lightweight, and rust- and weather-resistant. Rotomoulded plastic provides high density, is UV-stabilized, and is impact-resistant. They are also cost-effective and low maintenance. Stainless steel is corrosion-resistant (when treated or powder-coated) and highly durable. Vinyl is waterproof, flexible, resistant to abrasion, and affordable. Many of these characteristics are interchangeable among the materials.

The materials chosen for the slide will also determine its ease of installation—whether it will be a modular piece assembled on-site or prefabricated, allowing it to be mounted and secured in one piece.

Coatings such as epoxy or polyurethane (PU) further enhance the durability and safety of these materials. They can provide a glossy, smooth, low-friction surface and are often UV-stabilized to prevent fading and maintain surface integrity.

Guidelines and standards

The Pool & Hot Tub Council of Canada (PHTCC) has guidelines for pool slides. Key considerations include ensuring adequate water depth at the slide’s exit point (usually 1.2 to 1.5 m [4 to 5 ft]), appropriate flume and slope length to prevent injuries, and providing necessary anchoring to prevent the slide from tipping. More guidelines have been outlined, but the emphasis is always on safety.

The Canadian Standards Association (CSA) also has standards for pools and recreational equipment, more focused on the structural integrity of the slides, the materials used, the integration of slip-resistant elements, etc.

It is also important to know any local codes, as they vary and may have specific and/or mandated safety requirements for pool slides in residential settings. In Canada, weatherproofing is critical for outdoor elements (e.g. slides should withstand freeze-thaw conditions).

Municipal bylaws may also outline water depth requirements, any restrictions on height, or even placement within the property. For example, the City of Toronto requires a fence if there is a private swimming pool with height restrictions outlined.1 Another example is the amusement devices e-law in Ontario under the Technical Standards and Safety Act, 2000.2 It has criteria defining dry and water slides. For water slides, it states:

Water slides that meet the following criteria:

- the vertical height of the water slide, measured from its entry to the exit,

is 2 m or less, - the average angle of the water slide, measured from its entry to the exit,

is less than 6º, and - the maximum speed of the passenger on the slide does not exceed 2 m/s.

However, Ontario Regulation 221/01 governing the design and construction of amusement devices applies to those in public parks, playgrounds, play areas, and other similar settings. It does not cover residential areas, so one may refer to the Ontario Building Code (OBC).

Some municipalities may also require pre-installation approvals and/or post-installation inspection, so it is always best to verify.

Further, an international standard to look into is ASTM F1148, Standard Consumer Safety Performance Specification for Home Playground Equipment.

Additional elements

Beyond the slide’s structure, there are other factors to consider. For example:

- A water delivery system best accompanies water slides since it aids with lubrication. This can be done by connecting the water line to the pool pump system or using a separate hose.

- If the slide will be installed on a pool deck, assess its load-bearing capacity and space.

- Slides are anchored with stainless-steel or corrosion-resistant bolts to ensure stability; heavier slides may require concrete footing for additional support.

- Inform the customer of safety features needed, such as handrails, non-slip steps, edge guards, etc.

- Due to the pool environment, the slide may accumulate algae, dust, or debris. Non-abrasive cleaners are recommended to address this.

Slide, soar, and splash!

When selling customizable slides, considering various factors, such as design, dimensions, standards, and guidelines, is important. However, the rewards of doing so are significant. Customizable slides create a space for endless fun, allowing families to make lasting memories and enjoy summer from the comfort of their backyards. The longer a slide lasts, the more it enhances the relationship between the pool retailer or builder and their customer. With simplified installation procedures and versatile design options, a customized slide can seamlessly integrate into the backyard esthetic or stand out with a unique structure or vibrant colour. Pool retailers and builders must use durable, sturdy, and flexible materials to ensure quality, positively impacting the overall outcome.

Notes

1 Review this bylaw at www.toronto.ca/legdocs/municode/1184_447.pdf

2 See Ontario’s e-law on amusement devices at https://www.ontario.ca/laws/regulation/010221