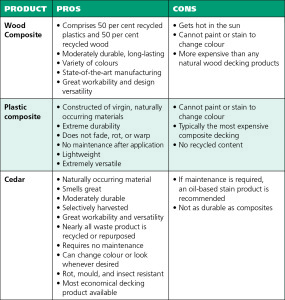

The differences between composite and natural building materials

Traditional wood decking

Wood decking does not contain recycled products, it is not formed in a factory, it does not need colour added or grains embossed into it, nor does the manufacturing process require numerous hazardous chemicals. Yet, to the majority of the general public, when it comes to green or environmentally friendly decking, traditional wood decking is often thought to be far worse for the environment than its composite counterparts.

There are many different options for wood decks; however, for the sake of comparison, a common cedar deck board will be used for the remainder of this section. Cedar decking is selectively harvested from sustainable growth forests. Many of the cedar deck boards used today are harvested from second growth forests. These are areas that have already been replanted once prior, and it is these smaller trees, which are being used as an alternative to larger, majestic, old growth trees.

After an area has been harvested, it is the harvester’s responsibility to replant and maintain the saplings in their block cutting (i.e. a forestry/logging practice in which most or all trees in an area are uniformly cut down) until the trees have reached a height the provincial forestry division deems good enough for the trees to grow on their own. Once the saplings have reached their ‘free to grow’ maturity, and access to these block cuttings are no longer needed, the haul roads are reclaimed and returned to their natural state as close as humanly possible.

Much of the actual tree felling is still performed by hand with chain saws in the steeper more treacherous areas in the alpine. This minimizes soil erosion and site degradation. A yarder is situated atop the block cutting and the felled trees are strung to a yarder line and hauled up the mountainside to the landing area. On gentler block cuttings, skidders are used to gather and bunch the felled logs and move them to the landing areas.

Once the raw materials have reached the landing areas, a processor cuts the logs to the longest lengths that fit on the haul trucks before they are shipped to the mill. Once at the mill the logs go through a number of selection processes to determine which are best suited for each product. Then, the log is processed and cut in order to minimize waste, and the raw boards are sent off for finishing. During the milling process, nearly 100 per cent of the waste product is repurposed. For example, waste wood chips are sent to paper mills, some products are turned into finger jointed siding or trim, bark chips and some wood chips are repurposed as animal bedding or bark mulch, and saw dust is collected and incinerated to generate power (e.g. steam power for heat) in local areas.

Cedar trees have naturally occurring chemicals, which deter rot, mould, and insects, and when left to the elements, turns a silvery patina colour. Because of these naturally occurring chemicals, end users can put as much or as little maintenance into their cedar deck as they deem necessary. When the cedar product has reached the end of its life cycle, natural untreated cedar is completely biodegradable, and can be recycled, repurposed, or reused.

Cedar is considered a soft wood, along with spruce, pine, and fir. Softwoods are not as durable as wood/plastic composite decking products; however, mahogany decking is extremely hard, durable, and more versatile than a composite deck board.

Cedar is considered a soft wood, along with spruce, pine, and fir. Softwoods are not as durable as wood/plastic composite decking products; however, mahogany decking is extremely hard, durable, and more versatile than a composite deck board.

Overall performance

Green building products are evaluated on their performance during all phases of their lifecycle—from design, construction, and operation to maintenance, renovation, and demolition. How these products react and interact with other products they interface with, and how they contribute to the overall performance of the project they are a part of, all contribute to how ‘green’ a building product is.

All decking material has its ‘green’ attributes. It is up to the end user to determine, which attributes they value more, and pursue the decking product, which mirrors their values best. With the advent of organizations such as LEED and built green, consumer awareness has been heightened with respect to green building products, which has created transparency between the manufacturer and consumer. Those builders who are interested in a particular product are urged to contact their supplier or even the manufacturer with any questions. Building ‘green’ and being environmentally aware is everyone’s responsibility. Builders who conduct their own research and choose the right products for the right applications are doing their part for the environment.

Joel Seibert, is the operations manager at Mountain View Building Materials in Calgary, Alta. They specialize in the design/build of decks, fences, and high-end residential exteriors. Seibert previously owned-and-operated a landscape construction company and is the third generation of the family to enter the lumber industry. He can be reached via e-mail at joels@mountainviewbm.ca.

Joel Seibert, is the operations manager at Mountain View Building Materials in Calgary, Alta. They specialize in the design/build of decks, fences, and high-end residential exteriors. Seibert previously owned-and-operated a landscape construction company and is the third generation of the family to enter the lumber industry. He can be reached via e-mail at joels@mountainviewbm.ca.