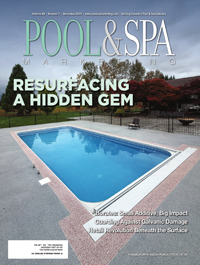

Transforming a vinyl pool into a custom concrete design

Au naturel

Working with the backyard’s natural surroundings, we decided to go ‘all natural’ with the renovation. Instead of a tiled border and symmetrical coping, which takes away from the natural feel of a pool, shotcrete was used on the coping and pool shell. Then, the concrete was carved to create the look of fractured rock.

This is not a consistent shoot, as it is intended to look as though the rock goes up and down the side of the pool, sometimes even protruding all the way to the pool floor. This creates the effect of a rock that had to be left pushing into the pool from outside the shell during the original build.

To create this look, we first had to remove the old liner and pool coping along with the steel steps at the end of the pool. As the pool had no bottom drain, and circulation was not being optimized; this had to be addressed.

The homeowners wanted the original pool’s pressure-side cleaner removed, which provided us with a plumbing line to install a Virginia Graeme Baker Act (VGBA)-compliant channel drain in the pool floor. We then added a light to the shallow end of the pool in what would become a bench and tanning shelf.

Steel was then installed to provide strength for the shotcrete application. The original pool walls were also left in place, as they were still very strong and provided a form for the shotcrete, which also allowed for a consistent shell depth. In this case, the deck and coping were left in place to become part of the new pool.

Gravel was placed in the void created by the removal of the pool steps and a steel cage was built to create the tanning shelf and benches. A new light niche was also added to the pool’s deep end to replace the original niche, due to deterioration and the need to accommodate the new shell.

The shoot begins

As usual, concrete was placed starting with the walls. However, because this was an existing pool with close proximity to the house and a finished stone wall, we did not add air to the shotcrete process. Mixing air with shotcrete is a messy process; in this case, a cleaner application was required. The existing floor of the original pool allowed us to use a 51-mm (2-in.) line pump to ‘stack’ the shotcrete without the need for air.

With the proper mix, this works well. Given the relatively shallow depth of the pool, there were no problems. Lathe, a strong wire-mesh material, was also attached to the existing steel walls, which allowed the new material to adhere properly to the original surface during shotcrete application.

As shotcrete placement begins to cover all the walls, we started to add more material to the coping area. A ‘carver’ then began to shape the shotcrete as it was built outward, beyond the walls. This is how the natural rock look was achieved. Texture pads and a release agent were also used on top of the coping to give it a natural effect. The benches were then finished and the floor poured.

Personnel is very important during this process. The coping has to be worked quickly enough to achieve the required look; otherwise, a secondary material like mortar has to be used to finish out the coping. When used in moderation, this is not necessarily a bad thing; however, too much can make the coping too heavy, which will have an effect on the long-term life of the pool’s finish. When the shoot was finished, a concrete pool-shell protector was applied to the entire shell and coping. This protects the concrete from deterioration and provides maximum efflorescence control.