Troubleshooting spa packs

Become acquainted with the control system

Most spa service technicians will agree, when performing a service call, the spa owner customarily follows the technician to the spa area and, after opening the box and finding a mass of parts and wiring that looks like a bowl of cooked spaghetti, they typically ask, “What do you think the problem is?” and “How much is this going to cost?”

Before coming to any quick conclusions, take the necessary time required to become familiar with the components and circuits. Identify them by getting the make and model of the control system and various components such as the circuit board and panel. Are there dip switches or jumpers that need to be configured for the equipment? What voltage does each piece of equipment require?

Before coming to any quick conclusions, take the necessary time required to become familiar with the components and circuits. Identify them by getting the make and model of the control system and various components such as the circuit board and panel. Are there dip switches or jumpers that need to be configured for the equipment? What voltage does each piece of equipment require?

To determine this, find the neutral bar or connections. Any load that connects back to neutral must be 120 volts. This information can also be used to determine pump and blower voltages. Then, with the power turned off, follow the various circuits. Cut any wire ties (reapply when the diagnostic is complete). Start at the source, follow through the various controls to the loads and follow back to the source. Look for common bridged connections and determine if these groups of connected wires are on the line side of the switch or load (controlled) side.

Look for any visible signs of a problem. Are there any burnt connections, brittle wiring, or charred contacts? Are any components rusted or corroded from poor equipment location? Does the pump seal look like it has been leaking for some time?

If the technician does not recognize and understand every part when examining the components, they should stop what they are doing and close up the box. If the person is not qualified, they may be endangering themselves and the customer. In this case, explain to the customer that it is necessary to refer back to the manufacturer in order to properly asses and correct the problem.

Is the spa properly installed?

Many spas are sold by mass merchants and installed by the consumer. Therefore, the technician will need to ensure the spa is installed properly and the GFCI (make sure there is one) is wired correctly. Another consideration is to make sure everything is properly grounded and bonded.

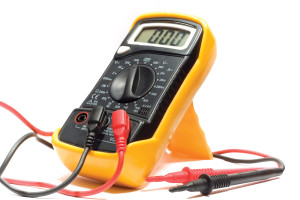

Test the supply voltage

Many faults are the result of improper source voltage, especially with solid state electronic systems. Determine the voltage at the panel, on line one, line two, as well as through neutral and ground. Next, test the incoming voltage at the control pad. Is it the same? A drop of as little as five per cent can cause contactors to chatter, motors to run hot, and key pad errors to appear.

Determine the problem

Use a multi-meter to check voltage on the line and load side of components, such as relays and the transformer. Check for proper voltage and amperage to the element as well as continuity through fuses and switches to find the faulty component. When testing continuity through switches, disconnect the leads to the component to prevent a false reading from the ‘backdoor’ of the circuit. When testing fuses, remove them from the holder—no voltage should be present.

For instance, when faced with a hot tub that is not heating, check the keypad. Is there a demand for heat and is the heater icon light on? If so, test the voltage at the element. Is there voltage at the element? If so, use an amp meter to determine if the element is drawing power. The amperage reading should equal the wattage of the element divided by the volts going to it. If there is proper voltage at the element terminals but no amperage draw, the element is faulty.