Using component systems to build caves and grottos

by jason_cramp | November 20, 2015 10:30 am

By Bruce Riley

[1]

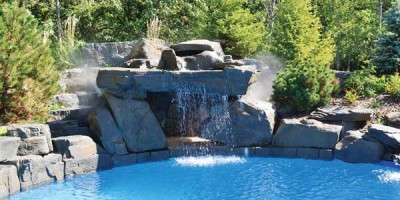

[1]Today, homeowners want pools with all the bells and whistles—not just diving boards and slides, but waterfalls and sundecks. A new trend, however, is the addition of an integral poolside grotto, complete with a cave, water feature, and slide. Previously, the only way to create a cave/grotto was to use heavy, expensive natural boulders or freehand carved artificial rock. Both of these options are labour intensive and can be stressful for designers/builders, as the finished look cannot be guaranteed. Consumers want to know exactly what they are getting in advance and pool builders need to be able to provide a cave/grotto with a consistent, predictable look at a reasonable price.

To meet this demand in the marketplace, suppliers have created component systems or ‘kits’ that are standardized, allowing builders to propose a product and guarantee it will look the same once it is built. Component cave/grotto kits allow pool builders and/or decorative concrete decking companies to offer these features at a competitive price to a wide range of customers all while guaranteeing an esthetically pleasing project. This article will explain how pool builders can market and sell cave/grotto features, the benefits of using component systems, as well as provide a general idea of how they are installed.

[2]

[2]Offering cave/grotto features

Most consumers ask about grottos/caves after they have seen one on a neighbour’s pool, at a hotel, in a photo in a magazine, or on the Internet. As a result, these features are becoming more prevalent in the pool design/build marketplace.

“We offer cave/grotto water features on all of our new pools, but we frequently add them on renovation jobs as well,” says Glen MacGillivray, president/owner of Aqua-Tech Pool, Spa and Bath in Winnipeg.

“Even if the consumer does not specifically ask for a cave/grotto, waterfall, or slide on their pool, it is a feature that should be presented because it makes pools more esthetically pleasing while at the same time increases the entertainment value of the backyard.”

Caves/grottos are basically a ‘super’ waterfall feature. They provide all the benefits such as visual beauty and the calming sound of cascading water, but also add an element of fun and excitement—especially for children.

Unlike artificial rock of the past, which was often cast from rubber moulds, today’s cave/grotto component systems look real because they are cast from actual rocks to provide the same shape, character, and texture. These systems are, in effect, a ‘kit’ that allows builders to show consumers a brochure of what the final product will look like at the time they sell the job.

Builders then order the kits that come with all of the materials necessary to complete the specific project. Each system is constructed by assembling and fitting each component together and they are designed to ensure proper water flow and weight distribution, and are structurally stronger than natural rock systems, as they are reinforced with steel.

Considering the client’s budget

When selling these features, as with any construction project, budget is always a consideration. Therefore, it is important to show a number of finish options to consumers to allow them to pick one within their budget.

“Most of our water features include caves/grottos which can cost between $5,000 and $30,000,” says MacGillivray. “Once you start adding additional options like slides and misters, costs can escalate quickly. In fact, we’ve completed some projects in the range of $150,000 for the entire system.”

Most builders will agree the cost of a custom cave/grotto feature, built using real rock, averages around $40,000; however, by using a component system, builders can offer the homeowner the same size feature (approximately 1.8 m [6 ft] wide by 3.6 m [12 ft] tall—from the deck to the top of the highest rock) at a cost between $15,000 and $20,000.

Landscaping is also integral to these water features, as it is important they fit naturally into the backyard landscape. When Aqua-Tech Pool, Spa and Bath first started offering these features, the company realized consumers were going to landscapers to have them built; however, without knowledge of pool construction and hydraulics an untrained installer may unintentionally create a water feature that can compromise the pool.

Constructing cave/grotto water features

Unlike MacGillivray, who is an experienced pool builder and landscaper, other potential contractors, such as deck builders, are also being introduced to the world of poolside caves/grottos.

Keefe Duhon, president of Concrete Revolution, a company specializing in decorative concrete construction, is one of them. When one of Duhon’s high-profile clients, Jacob Landry of History Channel’s Swamp People, approached him with the idea of adding a cave/grotto, waterfall, and waterslide feature to his pool, he presented Landry with the idea of constructing a component system he had seen at a trade show, despite never building one of these features.

“I was excited by the concept as I wanted to offer something that was guaranteed to be structurally sound, functional, and esthetically pleasing,” said Duhon. “It was also important for me to try something that didn’t involve a lot of labour-intensive, time-consuming work.”

As Landry wanted a slide integrated into the poolside feature, Concrete Revolution incorporated a modular unit designed to fit into the component cave/grotto system that was installed on his pool.

[3]

[3]The construction process

Since these components have a steel structure, a bond wire is required to meet most building codes. The concrete pad should have a bond break at the pool shell and should slope toward the pool. It is also recommended there be at least 102 mm (4 in.) of concrete on the pad. In addition, the construction of caves and grottos require concrete backfill.

Placement

Base components should overhang the pool beam by 25.4 to 51 mm (1 to 2 in.) to minimize any chance of seepage under the waterfall. The base components and ledgers generally have a dripline, but water might still run down the face of a rock. The most popular size cave/grotto is 3 m (10 ft) long and 1 m (3.5 ft) tall, with an approximate 1.2 m (4 ft) wide ‘cave area’ for sitting that is 0.5 m (1.7 ft) above the pool’s waterline.

Handholds

If the cave/grotto is placed in an area of the pool with more than 1.2 m (4 ft) of water, building codes typically require a ‘handhold’ to be installed. This can be done by setting the waterfall back from the beam about 51 to 76.2 mm (2 to 3 in.), but the beam must slope toward the pool to prevent seepage. In these cases, 228.6-mm (9-in.) coping is often used to create a handhold to extend the rock into the pool.

[4]

[4]Mortar techniques

Today’s component system castings can be quite dense and they do not absorb water so they must be set with a rich mortar mix. Most masonry supply businesses and home improvement stores have a ‘better quality’ mortar mix or cement that can be blended with masonry sand, which work well. Mortar should be easy to trowel into place—not too runny or stiff. Mortar beds should be 25.4 mm (1 in.) or more for base pieces and less for smaller rocks. For maximum bonding, mortar should also be scrubbed to the underside of the rock.

On a radius or corner, gaps need to be filled. The small rocks that come with each kit can be used or coping can be cut to fit and fill any gaps.

The mortar should be left to set; do not smear fresh mortar. After it has hardened, it can be cut and brushed away. A slight undercut will provide a nicer finish. Some installers use antiquing to age the joint after the mortar is dry, while others like to use rainbow cement for mortar so it will dry the same colour as the castings.

“We found it extremely easy to blend the seams,” says Duhon. “It gave us peace of mind to not have to worry about rain messing up colour matching as the rocks are pre-coloured. Having to only colour and blend the seams saves an incredible amount of time.”

[5]

[5]Esthetics and functionality

Not only is it important that the finished look of the cave/grotto can be predicted, but it is also critical that the water flowing over the rock feature (waterfall) actually circulates back into the pool. If it does not, the water can get underneath the waterfall and cause problems.

Many waterfalls built of natural stone have seepage problems because the bond between the stones and the mortar fails. Before the availability of component cave/grotto waterfall systems it was hard to ensure water would flow back into the pool after pouring over a mass of natural boulders due to the difficulty of placing the stones in a configuration that would force the water to go in a predetermined direction.

Water takes the path of least resistance, so every angle and crevice can potentially cause problems exponentially. Every natural boulder is unique; therefore, it is impossible to predict the outcome of the water flow. In contrast, all component systems have been tested and designed to ensure the water flows exactly as predicted, assuming the builder follows the installation instructions correctly.

Weight

Caves/grottos are an attractive poolside feature; however, when constructed out of natural boulders, they can be extremely heavy. Putting a large amount of weight on the edge of a pool can compress the ground and settle the entire pool. On the other hand, component systems are roughly one-fifth the weight of natural stone and are designed with a weight distribution per metre/foot that takes the pool into consideration.

Time

All pool builders and renovators know the importance of being able to determine exactly how much time it will take to execute each element of a particular job—not only to provide an accurate quote on the project, but also for planning and scheduling purposes.

“Building (water features) with natural stone can be unpredictable,” says MacGillivray. “A builder can spend all day arranging the natural boulders and then have the consumer come home to say they would like to see them arranged differently.

“It’s too much like artwork, too unpredictable, and the labour costs can quickly get out of control.”

When installing component systems, a crew of four workers can arrange everything in roughly half to a full-day.

“Of course a big cave/grotto job, with misters and a waterslide, can take approximately three weeks to complete,” says MacGillivray.

Training

Training is imperative to successfully building cave/grotto water features; therefore, partnering with a supplier that offers installer training can be important, as there are some tips and tricks that can make the builder’s job easier and more cost-effective.

“We started working with component systems almost 15 years ago,” says MacGillivray. “The way we build them today is different than how we did it when we first started. Experience is important to being an effective cave/grotto water feature builder.”

Most manufacturers are happy to provide their expertise. That said, new installers can count on the manufacturer to supply on-the-job technical support for first-time installations.

Adding slides, staircases, and other fun features

“It’s important to realize consumers are going to spend as much time sitting around the pool as they will be swimming in it; therefore, being able to create a complete backyard retreat is key to making the customer happy,” says MacGillivray.

A cave/grotto water feature can create a tranquil, natural setting around any pool. Most consumers who add caves/grottos have children or grandchildren, so they are looking for a feature that is not only fun, but also esthetically pleasing. Children immediately want to play under, jump off of, or slide down these water features, the latter component requiring the addition of a slide and the construction of a staircase.

Manufacturers are aware of this need so they offer component systems that allow builders to install modular rock staircases to incorporate slides into the cave/grotto feature. These staircases can often be built in one day, while a staircase constructed of natural boulders would generally take three to four days to install. The labour savings alone makes component systems a price-competitive option in the poolside hardscaping marketplace.

Today’s builders can offer a cave/grotto with a waterslide staircase for $2,000 to $3,000 versus $6,000 to $8,000 for an elaborate design simply by controlling the cost of the rock structure. Prior to component systems, these projects could easily go beyond their original quotes because of the unpredictable nature of using real boulders. The trend towards adding cave/grotto water features on pools should be embraced now that trained builders can add these easily to install component systems to their repertoire.

Editor’s note: All figures are in U.S. dollars.

[6]Bruce Riley is the managing director of RicoRock Inc., makers of cast-concrete rock, including component systems for building caves/grottos, waterfalls, and waterslide products for use in pool applications. Riley focuses on developing new products and managing commercial installations. He built rock-type pools in southern California for 25 years and now uses this experience to design standard waterfall kits for the company. He can be reached via e-mail at bruce@ricorock.com[7].

[6]Bruce Riley is the managing director of RicoRock Inc., makers of cast-concrete rock, including component systems for building caves/grottos, waterfalls, and waterslide products for use in pool applications. Riley focuses on developing new products and managing commercial installations. He built rock-type pools in southern California for 25 years and now uses this experience to design standard waterfall kits for the company. He can be reached via e-mail at bruce@ricorock.com[7].

- [Image]: http://poolspamarketing.com/wp-content/uploads/2015/11/2013-08-07-01.00.24-D.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/12/techniques_2013-08-07-00.58.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/11/techniques_Rico-Rock-9.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/11/techniques_Rico-Rock-8.jpg

- [Image]: http://www.poolspas.ca/wp-content/uploads/2015/11/techniques_Loveseat-Install3.jpg

- [Image]: http://poolspamarketing.com/wp-content/uploads/2015/11/Riley_Headshot.jpg

- bruce@ricorock.com: mailto:bruce@ricorock.com

Source URL: https://www.poolspamarketing.com/trade/using-component-systems-to-build-caves-and-grottos/