Using large diameter ceiling fans to improve indoor comfort

Effective air movement

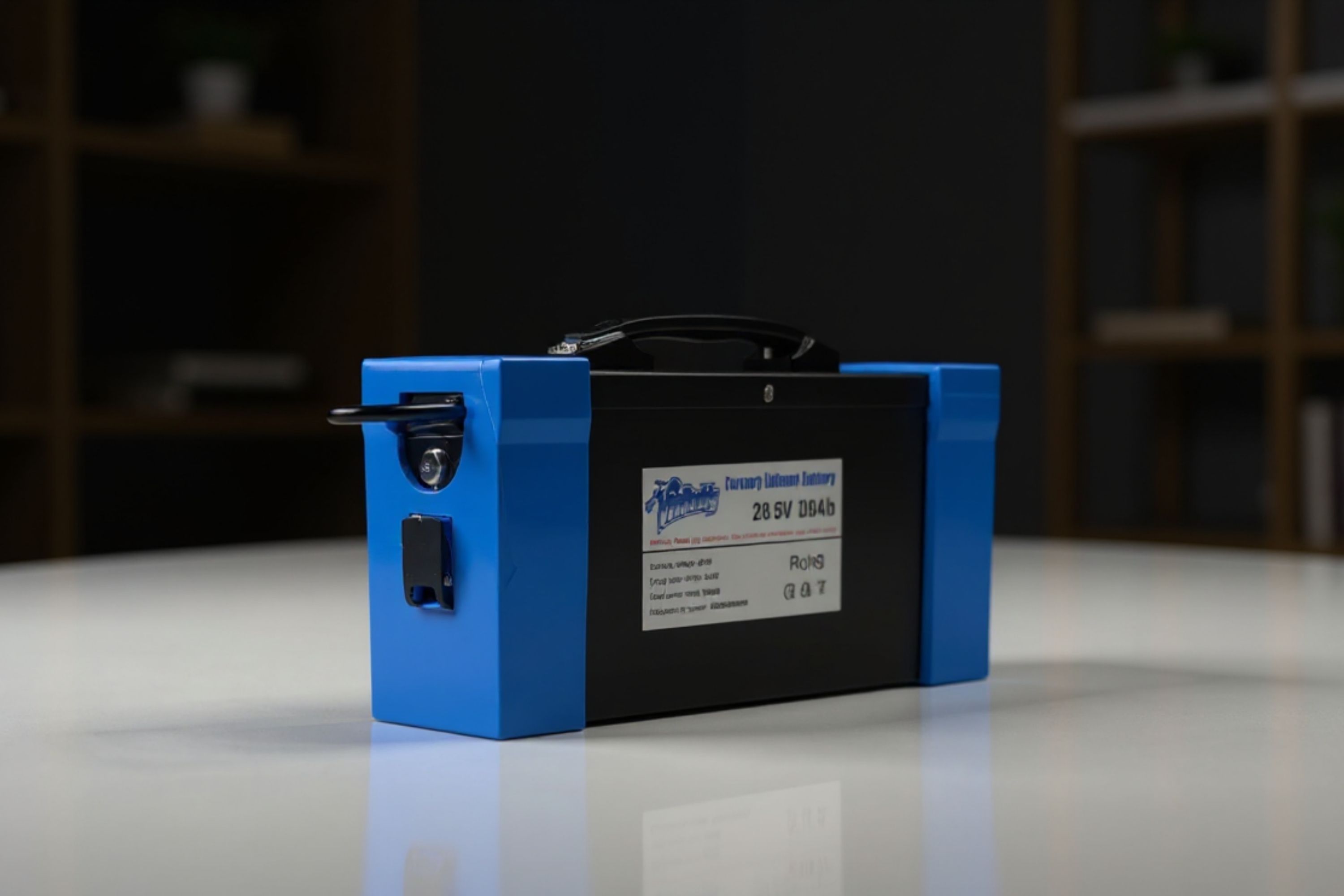

Effective air movement does not occur simply through fan rotation alone. The type of blades—or airfoils—and the angle at which they are placed play an important role. An angle approaching 30 degrees or more will increase drag and therefore require a larger motor, and consequently, move less air. This results in increased energy costs and lower aerodynamic efficiency. At the same time, a flat airfoil, which is almost horizontal, typically will not move much air either. To achieve efficient air movement and avoid excessive drag, a fan with 10 moderately-pitched, narrow-aerodynamic airfoils should be used. Similar to wings on an aircraft, airfoils allow for a much smaller energy-efficient motor. To further enhance airfoil efficiency, winglets are added at the tips to help eliminate wingtip vortices (tubes of circulating air) that can induce drag and lower overall airfoil efficiency.

Humidity control

Humidity control is crucial within all natatoriums regardless of location and size. The mix of chemicals, condensation buildup and bather loads also create indoor air quality concerns that can be addressed in a variety of ways including:

- extensive ductwork;

- exhaust systems; and

- air handling units.

These systems create a constant exchange of inside and outside air. Condensation is inevitable; however, HVLS fans work with ventilation systems to ensure fresh air reaches the occupant level with steady, constant motion. Regardless of the method used to exchange air, it is important to keep it moving around the water to dissipate chloramine gases. To reduce humidity, air is passed through air handlers and cooled to 12.7 C (55 F), which causes the humidity to condense out of the air, albeit energy usage increases. However, UT Austin, with guidance from Allen, designed a heating system that utilized waste heat from a nearby cogeneration plant.The system works by returning air from the pool deck to one of five separate units where it passes over a carbon impregnated filter bank to remove chloramines. Air is then cooled by a chilled-water coil, below saturation temperature, to induce condensation and remove water from the air. Once the air is cooled, it passes over a hot water reheat coil to return the air temperature back to the discharge air set point, which is modulated by thermostats in each individual space. Air leaves each unit free of chloramines, dry and at any range of temperature established by space requirements. Reheat for the units are accomplished indirectly via superheated waste steam from the university’s combined heat and power plant.

To make this work, the total volume of air movement was established based on the calculated evaporation rate of water in the facility. The vapour pressure of the pool water and air at design temperature was also taken into consideration.

The system works by returning air from the pool deck to one of five separate units where it passes over a carbon impregnated filter bank to remove chloramines. Air is then cooled by a chilled-water coil, below saturation temperature, to induce condensation and remove water from the air. Once the air is cooled, it passes over a hot water reheat coil to return the air temperature back to the discharge air set point, which is modulated by thermostats in each individual space. Air leaves each unit free of chloramines, dry and at any range of temperature established by space requirements. Reheat for the units are accomplished indirectly via superheated waste steam from the university’s combined heat and power plant.

Taking the LEED

HVLS fans can also be tied in with a facility’s automation system, allowing facility managers to control all of the ventilation systems together. This is important for aquatic buildings that operate as both recreational facilities with a known number of participants, and as competitive facilities where the number of occupants can increase dramatically over a short time.

Designing aquatic facilities with consideration of its occupants is essential to creating a quality environment. By lowering effective temperatures and increasing ventilation efficiency with silent, gentle-air circulation, HVLS fans enhance aquatic environments for all those using the space.

Proper application of these fans can also help a project earn points under the Canada Green Building Council’s (CaGBC’s) Leadership in Energy & Environmental Design (LEED), a green building certification system providing third-party verification that a building utilized environmentally friendly building practices during construction.

Nina Wolgelenter is a senior writer for Big Ass Fan Co., a designer and manufacturer of high volume/low speed (HVLS) ceiling and vertical fans in Lexington, Ky. She has a background in environmental education and journalism. Her work on energy conservation, sustainability and the impact of HVLS technology across various industries has been published in magazines, newspapers and online media outlets. She can be contacted via nwolgelenter@bigassfans.com.

Nina Wolgelenter is a senior writer for Big Ass Fan Co., a designer and manufacturer of high volume/low speed (HVLS) ceiling and vertical fans in Lexington, Ky. She has a background in environmental education and journalism. Her work on energy conservation, sustainability and the impact of HVLS technology across various industries has been published in magazines, newspapers and online media outlets. She can be contacted via nwolgelenter@bigassfans.com.